- +86 188 2072 7151

- Lucy@dgsw888.com

- Building 33, Block B, Wanyang Zhongchuang Zone, Yangqiao Town, Huizhou City, Guangdong

Material: PVC plastic

Size:3*2(cm)/3*4(cm)/4*5(cm)/custom

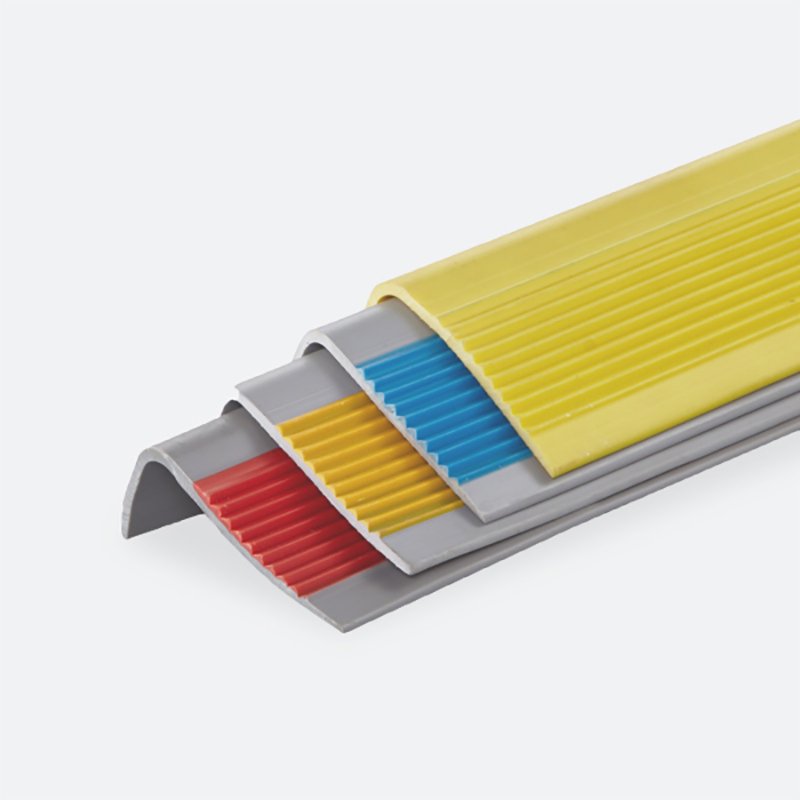

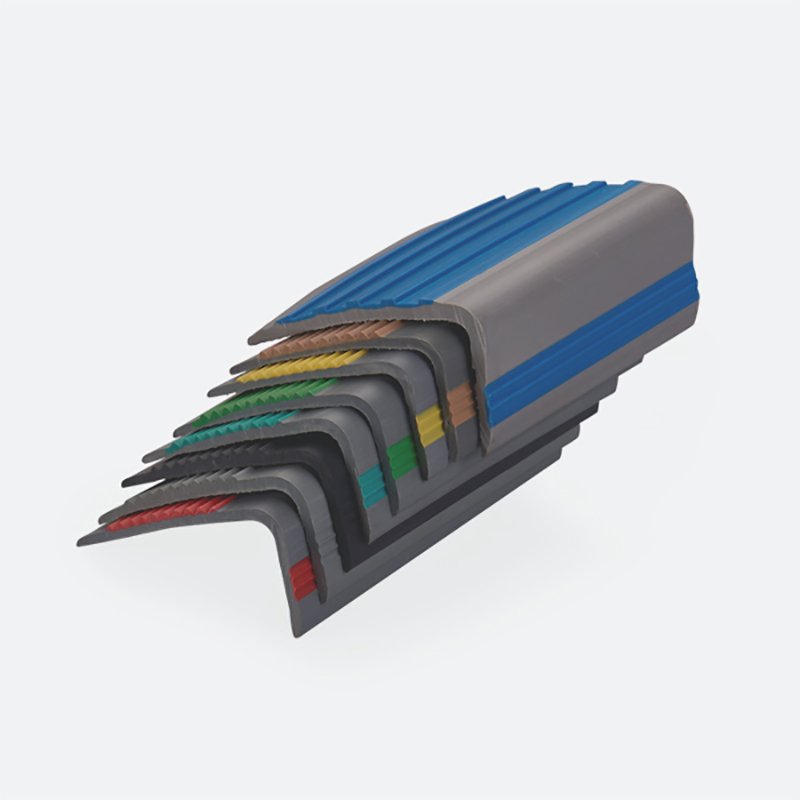

Colors:Yellow/red/blue/gray/customized

Thickness:Customized Thickness

Length: 10m/20m/30m/50m/customized

Feature:High anti-slip

Working Temperature:-20-135°c

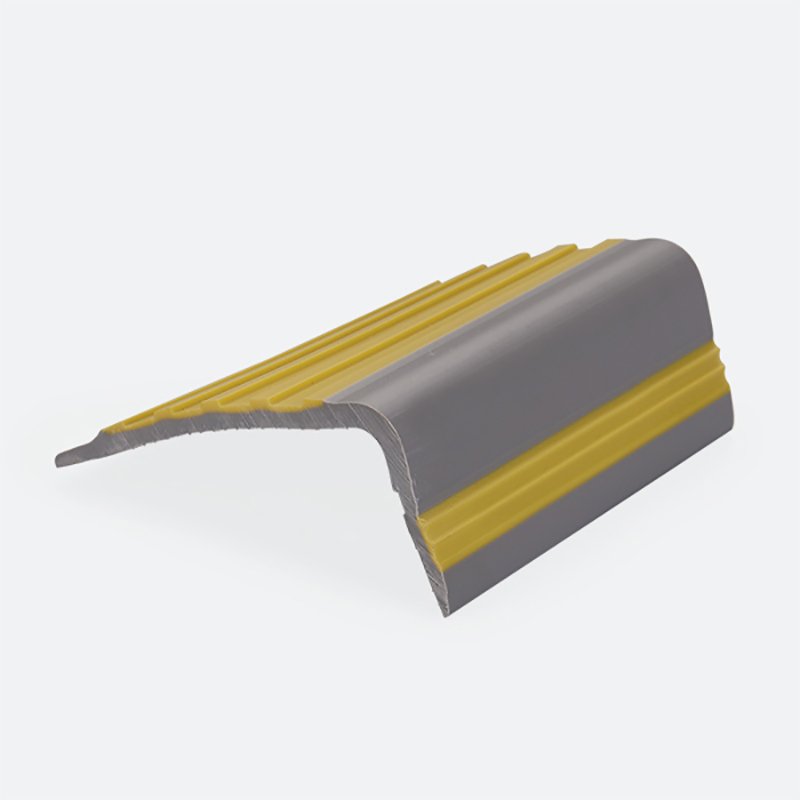

PVC anti-slip strip is a safety protection device installed in slippery areas such as stairs and steps. It is made of high-quality PVC material and has the characteristics of anti-skid, wear-resistant, and easy to clean.

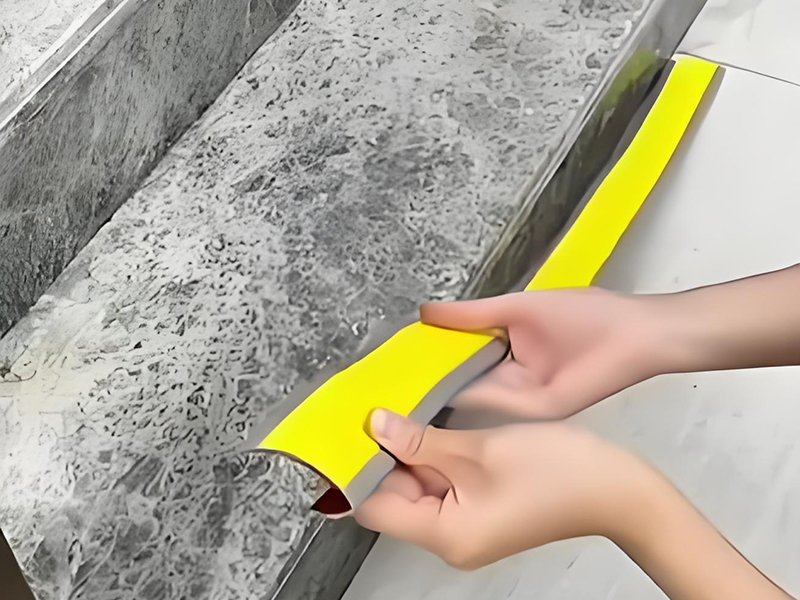

PVC anti slip strips effectively prevent falling accidents caused by smooth ground by increasing the friction on the tread surface, especially suitable for stairs made of smooth materials such as tiles and stone.

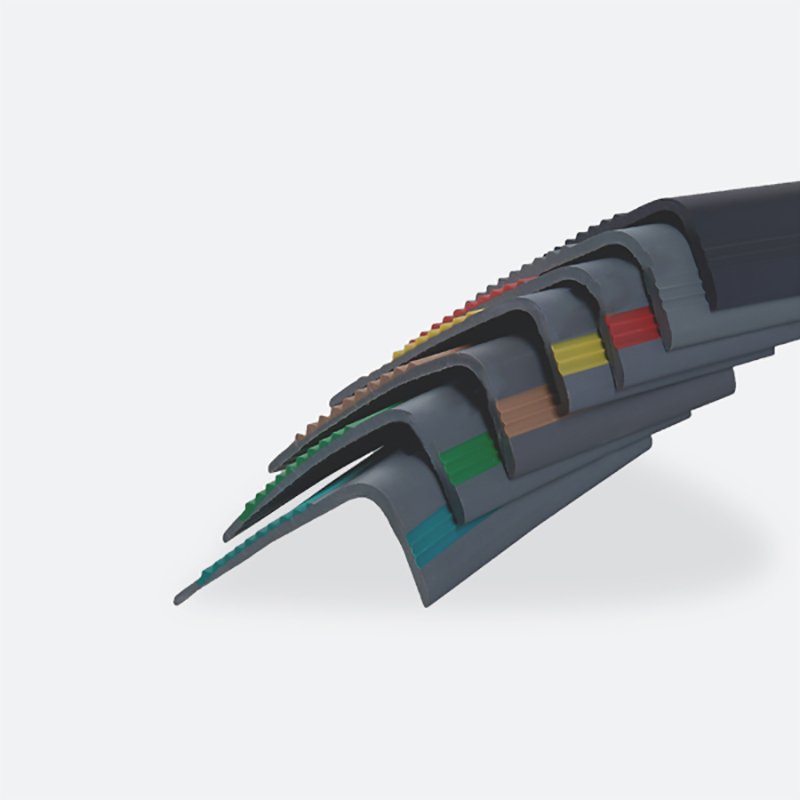

PVC anti-slip strips are mainly made of PVC, with a soft texture and strong weather resistance. They can adapt to various climatic conditions and are widely used in public places such as homes, shopping malls, and office buildings for stair treads, ramps, and other areas. They have both protective and decorative functions.

| Categories | PVC anti-slip strip |

| Material | High quality PVC |

| Brand | Your LOGO |

| Color | Yellow/red/blue/gray/customized |

| Size/shape | 3*2(cm)/3*4(cm)/4*5(cm)/custom |

| Thickness | Customized |

| Length | Customized |

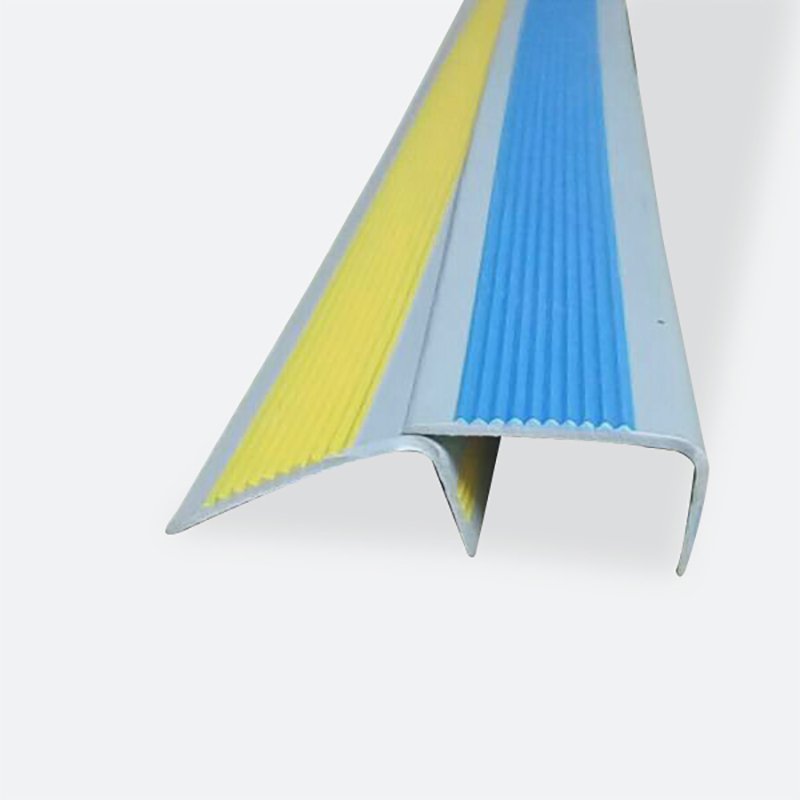

| Shape | L-shape/I-shape/customized |

| Processing Service | Cutting |

| Plastic Modling Type | Extruding |

| Application | Anti slip/Floor/staircase/house/hotel/school |

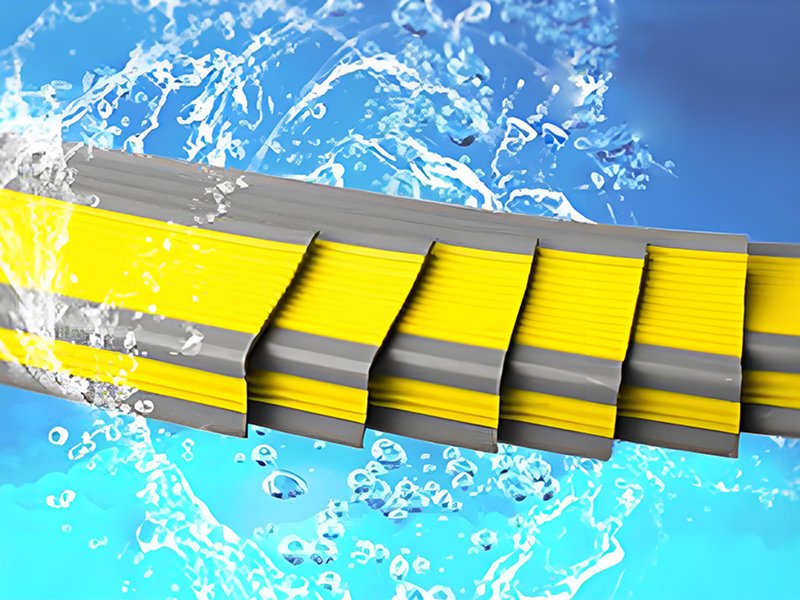

| Feature | Anti slip/waterproof |

| Standard | ISO 9001 ISO14001 ISO45001 cqm |

| Design | Custom according to your drawing |

| Net Weight | According to drawing |

| OEM/ODM | Accept |

| Packing | Customized |

| Packing material | Carton |

| Packing size | Customized Packing |

| Shipping | small quantity 3-7 days by FedEx, UPS, DHL, TNT or EMS or by sea or air for large quantity |

| Payment terms | TT & Paypal & Western Union |

| Certification | CE, CCC, CQC,ROHS |

| Delivery Time | 7-10 days for making mold and sampling, 7-30 days production depends on different quantity |

The surface adopts a fish scale pattern design, which improves the anti slip effect by increasing friction, and the anti slip coefficient can reach 0.6 or above

Made of high-quality PVC material, it has strong corrosion resistance, is not easily aged or deformed,waterproof and has a long service life

The material is environmentally friendly, safe, non-toxic, and pollution-free, suitable for places such as homes, hospitals, schools, etc. that require a balance between aesthetics and safety

Simple daily cleaning, diverse colors, flexible matching, can meet the needs of different decoration styles

At Shuowei, we’ve refined our service architecture over 20 years and 3,000+ global projects to transform complex profile challenges into competitive advantages. Here’s why manufacturers from Munich to Mumbai trust our rigorously engineered process.

Customization process:

1. Contact us: Clarify the purpose of PVC ant-slip strip, if you have specific requirements specifications,please send an email or WhatsApp to contact us(+86 188 2072 7151)

2. Prepare Raw Materials: According to the purpose and performance requirements of the extruded profiles, PVC or PE ABS PP PMMA raw materials with different polymerization degrees and models can be selected.

3. Extruder preheating: The heating device heats each section of the extruder barrel to the set temperature. Generally, the material is divided into the feeding section, compression section and metering section, and the temperature of each section is different.

4. Extrusion molding:Add the mixed dry blend into the preheated extruder barrel. As the screw rotates, the material is transported forward in the barrel. Finally, under the action of the die, the designed shape is extruded.

5. Cooling & Shaping: The PVC anti-slip strip extruded from the extruder head has a high temperature and needs to be cooled and shaped immediately to maintain its shape. Usually a vacuum sizing water tank is used for cooling and shaping.

6. Sample testing: If the sample test is qualified, a batch order will be placed. If it is unqualified, the sample will be remade.

7. Mass production: Sign a bulk purchase and sale contract.After confirming the samples, the production stage will be entered. The printing quality (such as ink dots and registration deviation) and die-cutting accuracy will be monitored.

Conventional products are 0.6-1.6MPa, and customized products can reach up to 2.5MPa (such as fire-fighting pipes).

A: Standard products comply with BS EN 61386 flame retardant B1 level, and can be customized to V-0 level (UL94).

A: -40℃~120℃ (short-term resistance to 150℃), suitable for automotive engine compartment parts.

±0.1mm (precision grade) or ±0.3mm (general grade), which is better than the national standard GB/T 8814.

Supports 3-layer co-extrusion, color difference ΔE≤0.5, surface hardness ≥2H (such as high-end decorative lines).

Only purchase from TOP5 manufacturers such as Dow Chemical and LG Chemical, and each batch is accompanied by the original factory warranty.

18 inspection nodes: raw material entry inspection → online diameter gauge monitoring → 72-hour weathering test, etc.

Free replenishment during the warranty period (defect evidence must be provided), and a rectification report will be issued within 48 hours.

It is recommended to use a cold-resistant formula (-40℃ impact strength ≥50kJ/㎡), which has been applied to Canadian municipal projects.

Medical-grade PVC is certified by ISO 14644-1, and the TVOC release is ≤0.01mg/m³.