PVC panel factory & solution

PVC panels have been widely used in our daily life. As a leading PVC panel manufacturer, our goal is to enhance the application value of PVC panels.

What is the PVC Panel

PVC Panel is a plastic grooved board made primarily from polyvinyl chloride (PVC), with added ingredients such as foaming agents, flame retardants, anti-aging agents, and polytetrafluoroethylene. Its production process includes PVC foam extrusion, cold water cooling, surface crusting treatment, and vulcanization molding. It is primarily used in brand chain stores, display racks, wall storage, office decoration, residential partitions, public building partitions, interior decorative panels, and automotive parts displays.

PVC panel is fire-resistant (oxygen index greater than 40), waterproof, insect-resistant, and formaldehyde-free, meeting environmental standards. It features a modular design with 49 configurations ranging from 20×15 to 100×100. Installation methods include pre-buried wooden brick fixing, plastic expansion tube fixing, and umbrella bolt fixing. The addition of modified potato starch, keratin fiber, and inorganic fillers significantly enhances its mechanical strength, wear resistance, and load-bearing capacity, preventing brittle fracture. It is suitable for use as panels and ceiling tiles in supermarkets, warehouses, garages, cleanrooms, and other applications.

What materials are extruded Panels made of

Extruded panels, also known as extruded plastic foam board, is a lightweight, high-strength, and excellent thermal insulation building material widely used in a variety of fields, including construction, transportation, home furnishing, and industrial applications. Common extruded plastic board materials include a variety of different materials, the main ones being:

PS panel: made from polystyrene resin through an extrusion foaming process, it features a closed-cell honeycomb structure, offering excellent thermal insulation and high compressive strength.

PP Panel: made from polypropylene resin with toughening and flame retardant chemical additives, it is melt-extruded. It offers high-temperature resistance (up to 100°C), high strength, and corrosion resistance, making it suitable for use in construction and building materials.

PVC Panel: Polyvinyl chloride (PVC) is primarily composed of polyvinyl chloride resin, supplemented with additives such as stabilizers and foaming agents. It is produced through an extrusion process and offers corrosion resistance, insulation, and UV resistance. It is commonly used in building panels.

PE Panel: It has excellent chemical stability, superior insulation properties, and resistance to acid and alkali corrosion. It also has low density and excellent toughness. It is also commonly used in water pipes, medical devices, and other applications.

WPC Panel: Wood fiber or wood powder is mixed with plastic (such as polyethylene, polypropylene, or polyvinyl chloride) and formed through extrusion or compression molding. It produces an appearance similar to natural wood while combining the durability and environmental friendliness of plastic.

ABS Panel: ABS panel is an emerging material in the panel industry. It organically combines the properties of PS, SAN, and BS, offering excellent mechanical properties with a balanced balance of toughness, hardness, and rigidity.

Application scope of PVC panel

PVC panel is a board made of polyvinyl chloride material, which is popular for its excellent physical properties and chemical stability. It has a wide range of applications in many fields.

More Industry

How to Custom PVC Panel

Demand Communication: Clarify customization requirements, including size, color, quantity, and functionality.

Material Selection: Select the appropriate PVC sheet type based on the intended use, such as rigid or flexible, and whether any special properties are required.

Design and Prototyping: Provide a design draft or sample, and after verification, proceed to mass production.

Production and Quality Inspection: The factory manufactures the product to your specifications and conducts quality inspections to ensure compliance with standards.

Delivery and Installation: After delivery, the finished product can be installed or further processed as needed.

Products

Let's see PVC Panel SW recommend

How to choose PVC panel manufacturer

When choosing a PVC panel manufacturer, you need to consider factors such as material performance, production capacity, and after-sales service. Specific suggestions are as follows

PVC Panels FAQs

Q: How is the price of custom PVC panel calculated?

A: The price is generally calculated based on a combination of material, size, craftsmanship, and quantity. Small orders may be more expensive.

Q: How long does the customization process take?

A: Generally, it takes 3-7 business days. Complex craftsmanship or large orders may require longer hours.

Q: Can PVC panel be used outdoors?

A: Yes, but you must choose UV-resistant sheets. Long-term exposure may cause fading or degradation.

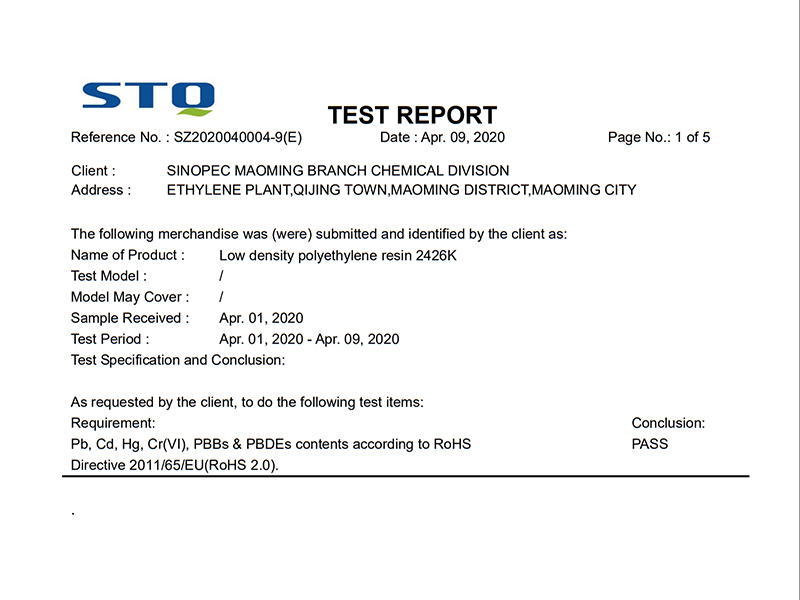

Q: Is PVC panel environmentally friendly?

A: Qualified PVC panel meet ISO 9001 environmental certification and are free of harmful substances.

Get in touch

As a 20+ years custom PVC panel factory, we have a team of skilled engineers ready to support you in your product development journey from prototyping to production.Any ideas about your product you can contact us freely,and our engineers will get back to you with a quote as soon as possible.