Extrusion lampshade solutions

SW is a 20+ years manufacturer specializing in the production of extruded lampshades. Our experts provide you with the best solution for PVC lampshade, PP lampshade, PC lampshade……

What is the lampshade

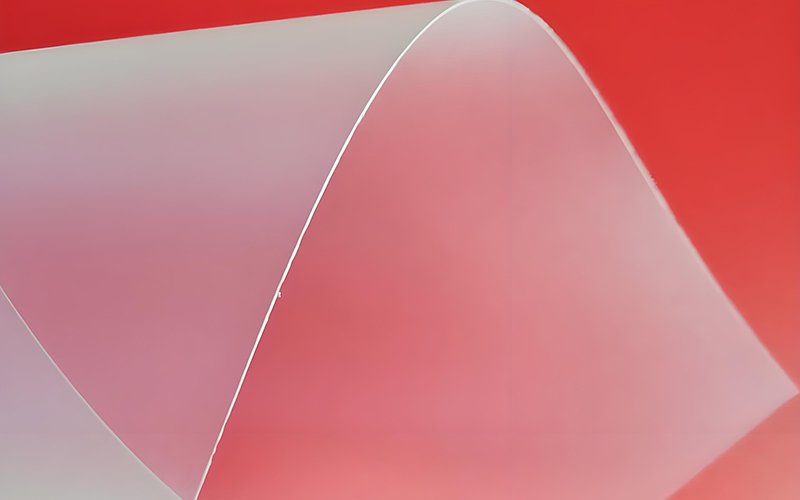

LED lampshade is a supporting component of LED lighting fixtures, mainly used to adjust the distribution of light. It reduces glare by scattering or concentrating light, making the lighting softer and more uniform, with a maximum transmittance of 94%. According to the material of the product, there are mainly PC lampshades, PVC lampshades, PP lampshades, acrylic lampshades, glass lampshades, plastic lampshades, paper lampshades, etc., which need to meet the characteristics of high light transmittance, strong diffusion, flame retardancy and impact resistance to adapt to the characteristics of LED light sources.

What materials are available for lampshades

There are many lampshades made of different materials, each with their own advantages and disadvantages

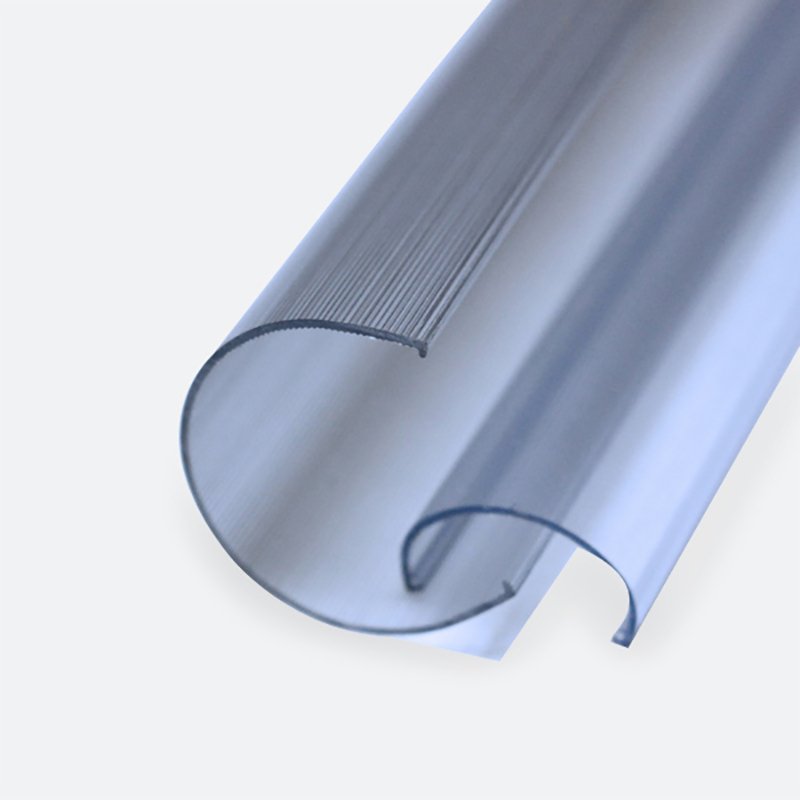

PVC lampshade

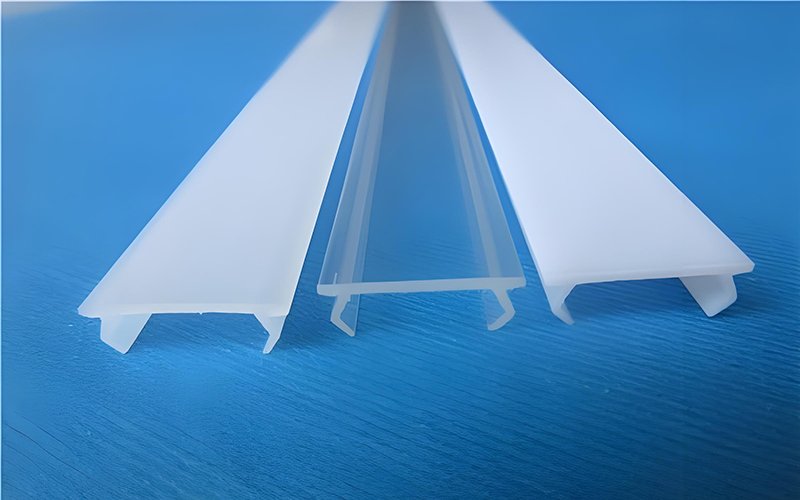

PC lampshade

PP lampshade

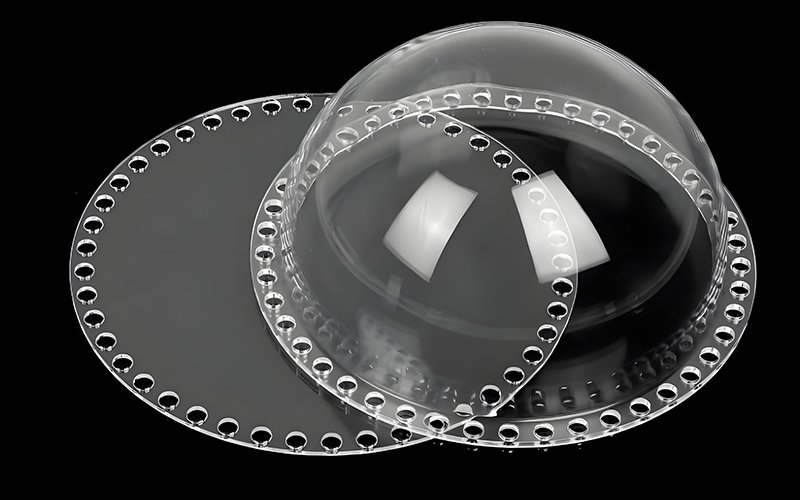

Acrylic lampshade

How to produce the PVC lampshade

LED lampshade is a part of LED lighting fixtures, used to protect LED beads from external environmental influences, while also playing a role in beautification and heat dissipation.

1.Production process: The production process of LED lampshades can be divided into various methods such as injection molding, extrusion, stamping, blow molding, etc. Each method has its unique characteristics and scope of application, and choosing the appropriate process has a critical impact on the quality and appearance of LED lampshades. Usually, PVC lampshades are produced by extrusion

2.Material selection: LED lampshades are usually made of plastic materials such as PVC PC, PMMA, PS, etc. These materials have good transparency and weather resistance, which can meet the usage needs of LED lamps in different environments. The quality of materials is directly related to the service life and safety of LED lampshades, so careful selection of materials is necessary.

3.Design innovation: The design of LED lampshades can be innovated according to different lamp shapes and uses. By designing a reasonable structure and shape, the light scattering effect and aesthetics of LED lampshades can be improved, making them better suited to different lighting scenarios and style requirements.

4.Quality control: As an important component of LED lighting fixtures, the quality of LED lampshades directly affects the overall performance and safety of the lighting fixtures.

5. Customized services: LED lampshade manufacturers can provide customized services for different customers’ personalized needs, including color, size, pattern, and other aspects of customization.

In the production process, it is necessary to strictly control the material procurement, production process, and finished product inspection to ensure that the quality of LED lampshades meets the standard requirements.

Production process of extruded PVC lampshade

How to choose a PVC lampshade factory

- Professionalism and experience: Choose manufacturers with rich production experience and professional technology, such as Shuowei New Material, who can provide higher quality products and services. They usually have advanced production processes and equipment, as well as a sound quality management system.

- Product types and specifications: Ensure that the manufacturer can provide the required types and specifications of LED lampshades. For example, SW’s main products include LED bulb lampshades, ultra semi-circular lampshades, and large angle illuminated PC lampshades, which can meet the needs of different customers.

- Customization capability: If specific specifications or designs of LED lampshades are required, manufacturers with customization capabilities should be selected. They are able to personalize design and production according to customer needs.

- Quality inspection: When selecting LED lampshades, strict quality checks should be conducted on the product. Including the transparency, weather resistance, impact resistance, etc. of the lampshade, to ensure that the product meets the requirements for use.

- Price and cost-effectiveness: While paying attention to price, we should also consider the cost-effectiveness of the product. Choose LED lampshades that are reasonably priced and of high quality to achieve maximum economic benefits.

- After sales service: Understand the manufacturer’s after-sales service policy to ensure timely resolution of any issues encountered during use. Good after-sales service is an important factor that cannot be ignored when choosing a manufacturer.

PVC lampshade tips

- Installation precautions

Power off operation: Before replacing or installing the lampshade, the power supply of the lamp must be turned off to avoid the risk of electric shock.

Size matching: Ensure that the lampshade size fits perfectly with the lamp frame to avoid deformation or light leakage caused by size differences.

Fixing method: Fix the lampshade with screws or buckles to ensure its stability and prevent it from falling off. - Precautions for use

Avoid high temperature environment: PVC material has limited temperature resistance, and prolonged exposure to high temperature environments (such as high bulb power or poor heat dissipation) may cause deformation or aging.

Regular cleaning and maintenance: Wipe the surface dust with a soft cloth to avoid scratching the lampshade with hard objects, which may affect its transparency.

Check sealing: If the lampshade is found to be loose or poorly sealed, it should be adjusted or replaced in a timely manner to prevent mosquitoes or rainwater from entering. - Maintenance precautions

Polishing treatment: If there are scratches or yellowing on the surface, 800-2000 grit sandpaper can be used to polish and restore luster (attention should be paid to controlling the strength and temperature).

Replacement suggestion: When the lampshade is affected by aging, deformation, or damage that affects the lighting effect, it should be replaced in a timely manner.

Advantages and disadvantages of PVC lampshade

PVC lampshade advantages

Affordable price: PVC material has a lower cost, suitable for large-scale production and consumption, and is suitable for consumers with limited budgets.

Lightweight and easy to install: Lightweight, easy to install and transport, especially suitable for scenarios that require frequent replacement or movement.

Good weather resistance: After special treatment, it can resist environmental factors such as ultraviolet rays and high temperatures, and is not easily discolored or aged.

Strong impact resistance: Compared to other plastic materials, PVC is more resistant to drops and less prone to breakage.

PVC lampshade disadvantage

Insufficient transparency: The light penetration rate is about 80%, resulting in relatively weak lighting effects, which need to be improved by adding coatings or pigments.

Poor environmental friendliness: harmful substances may be released during the production process, and recycling is difficult.

Long term use is prone to aging: Prolonged exposure to direct sunlight or high temperatures can cause oxidation, yellowing, discoloration, or cracking.

Products

Let's see PVC lampshade SW recommend

Get in touch

As a 20+ years custom PVC lampshade factory, we have a team of skilled engineers ready to support you in your product development journey from prototyping to production.Any ideas about your extrusion PVC lampshade you can contact us freely,and our engineers will get back to you with a quote as soon as possible.