Lighting has transformed in recent years, with LED technology becoming the global standard for energy-efficient illumination. As the LED industry expands, so does the demand for high-quality, durable, and stylish PVC lampshades. A well-designed lampshade not only protects the light source but also enhances the aesthetics and functionality of lighting products.

At SW, a professional plastic extrusion manufacturer with decades of expertise, we specialize in producing PVC lampshades tailored to the needs of modern LED lighting. In this comprehensive guide, we’ll walk you through:

Why PVC is an ideal material for LED lampshades.

The extrusion process for producing PVC lampshades.

Customization options to achieve unique designs.

Technical considerations for LED applications.

Advantages of choosing a professional PVC lampshade factory like SW.

By the end of this article, you will have a complete understanding of how custom PVC lampshades are manufactured and how to select the right one for your LED lighting projects.

1. Why Choose PVC for LED Lampshades?

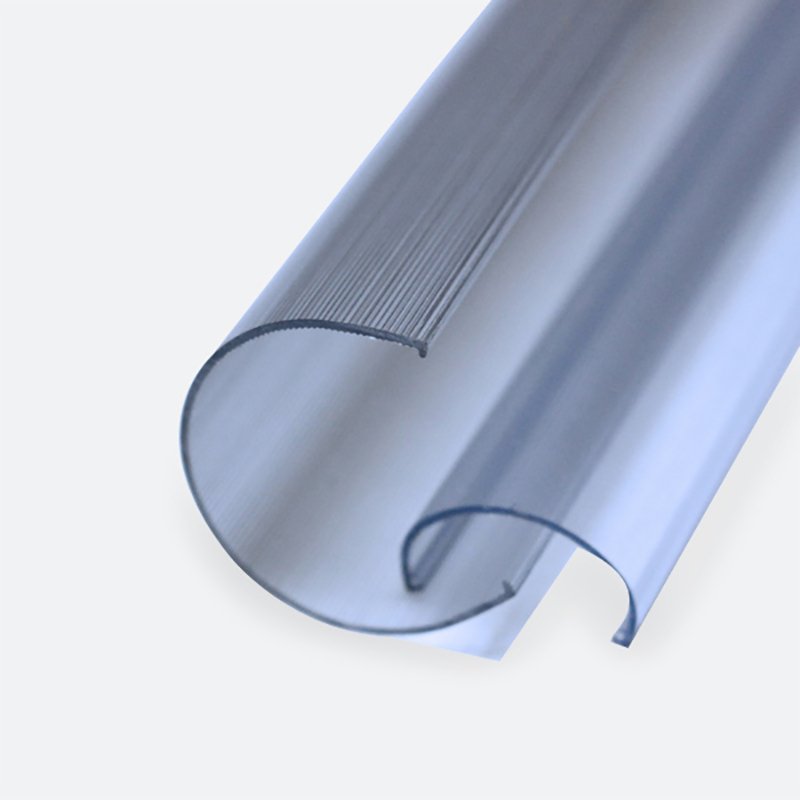

Among various plastics used for lampshades (such as PP, PC, ABS, and acrylic), PVC (Polyvinyl Chloride) stands out for its balance of performance, cost, and versatility.

Key Advantages of PVC Lampshades

Durability: PVC is strong enough to resist impact while remaining lightweight.

Heat resistance: With proper additives, PVC can handle the moderate heat emitted by LEDs.

Light diffusion: PVC can be extruded in translucent or frosted finishes to create soft, even light diffusion, reducing glare.

Cost efficiency: More affordable than PC or acrylic, making it suitable for mass production.

Customizable appearance: PVC can be colored, textured, or patterned to match different lighting designs.

Moisture and chemical resistance: Perfect for both indoor and outdoor lighting applications.

In short, PVC lampshades strike an excellent balance between aesthetics, functionality, and affordability — which is why they are a popular choice in LED lighting manufacturing.

2. Understanding the PVC Lampshades Extrusion Process

Producing a PVC lampshade requires precision engineering, modern extrusion equipment, and a well-structured production workflow.

Step 1: Material Preparation

High-quality PVC resin is selected as the base material.

Additives such as heat stabilizers, UV stabilizers, plasticizers, and pigments are mixed in to enhance performance and durability.

The compound is blended to ensure consistency.

Step 2: Extrusion

The PVC compound is fed into the extruder where it is melted and homogenized under controlled temperatures.

Through a specially designed extrusion die, the molten PVC is shaped into the desired lampshade profile (cylindrical, conical, rectangular, etc.).

Cooling systems solidify the material as it exits the die, maintaining its precise dimensions.

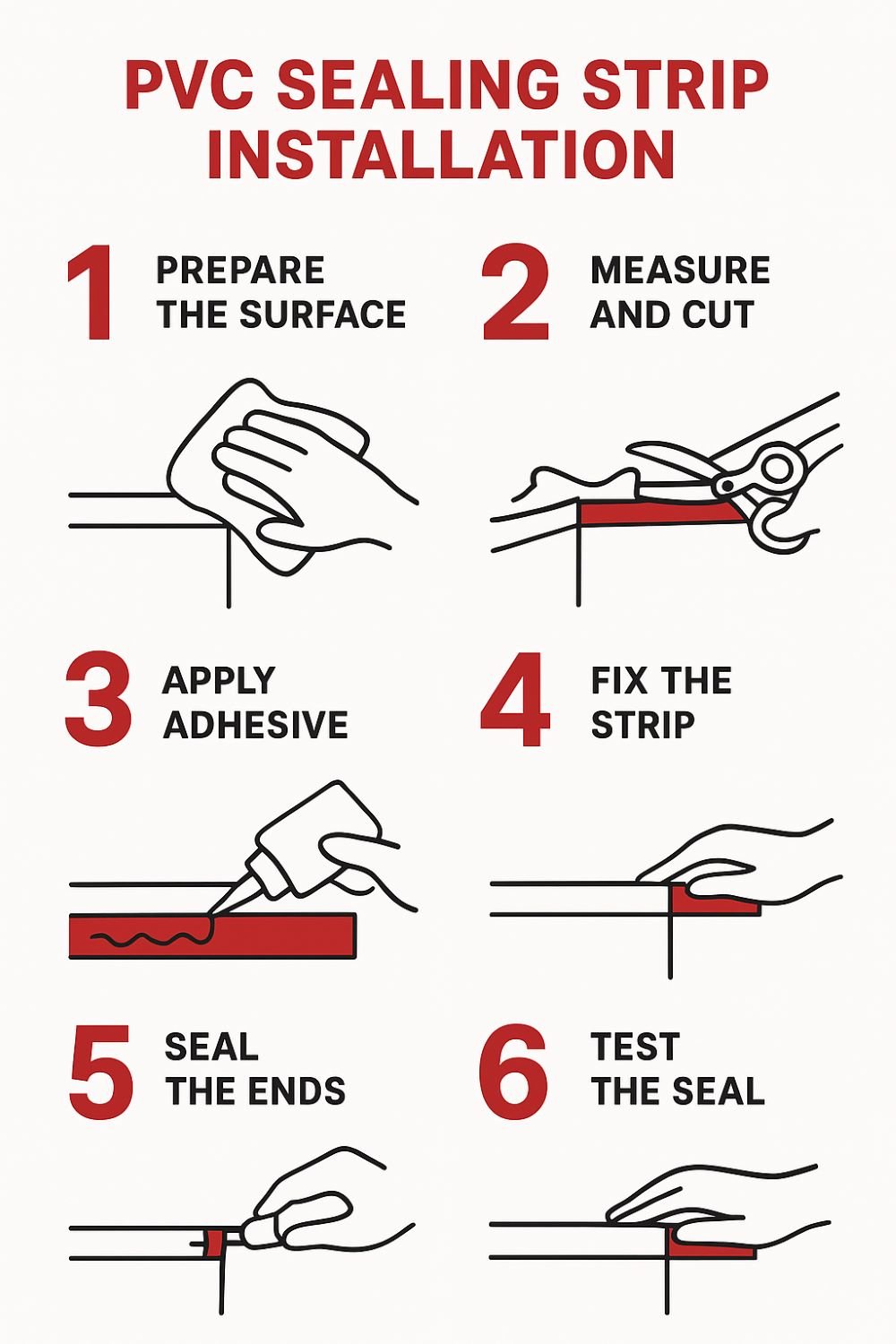

Step 3: Cutting and Forming

Extruded PVC tubes or profiles are cut to length.

If necessary, secondary forming processes (such as thermoforming or bending) are used to achieve unique shapes.

Step 4: Surface Finishing

Finishing techniques include frosting, polishing, or applying a textured pattern.

The lampshade can also be printed or painted for decorative purposes.

Step 5: Quality Inspection

Lampshades undergo rigorous dimensional checks, heat resistance tests, and optical performance evaluations.

Only products meeting international quality standards are approved for shipment.

This extrusion process allows for high-volume, cost-effective, and consistent production of PVC lampshades, making it ideal for LED lighting manufacturers.

3. Customization Options for PVC Lampshades

One of the greatest strengths of PVC lampshades is their ability to be customized. At SW, we offer a wide range of design possibilities to meet different lighting applications.

1) Shape and Size

Cylindrical

Conical

Dome-shaped

Rectangular or square profiles

Miniature lampshades for compact LEDs

2) Surface Finish

Transparent for maximum light transmission.

Translucent/frosted for soft diffusion.

Opaque with inner reflective coating to direct light.

Textured (striped, dotted, or patterned) for unique effects.

3) Color Options

Classic white or cream for residential use.

Clear or frosted finishes for commercial lighting.

Colored shades (red, blue, green, amber) for decorative purposes.

4) Functional Enhancements

UV-resistant PVC lampshades for outdoor use.

Fire-retardant formulations for compliance with safety standards.

Anti-static treatment to minimize dust attraction.

Through these options, customers can develop custom PVC lampshades that perfectly match their LED product design and brand identity.

4. Technical Considerations for LED PVC Lampshades

When designing a PVC lampshade specifically for LED applications, there are several key factors to consider.

Light Diffusion

LEDs are point light sources that can cause glare. A frosted or translucent PVC lampshade helps create soft, even light distribution.

Heat Management

Although LEDs generate less heat than incandescent bulbs, heat buildup inside enclosed fixtures must be considered. PVC must be properly stabilized to withstand prolonged exposure to moderate temperatures.

Optical Properties

Choosing the right thickness and finish affects brightness and diffusion. For task lighting, thinner and more transparent shades are preferred, while for ambient lighting, frosted finishes are ideal.

Safety Standards

Custom PVC lampshades must comply with UL, CE, or RoHS standards, ensuring fire safety, non-toxicity, and long-term durability.

Compatibility with LED Fixtures

Designs should account for fixture dimensions, bulb positioning, and installation methods. Extruded PVC lampshades can be engineered with clips, grooves, or fittings for easy assembly.

5. Advantages of Choosing SW as Your PVC Lampshade Factory

At SW, we don’t just manufacture lampshades — we deliver custom-engineered lighting solutions.

Why Work With Us?

30+ years of extrusion experience – We understand every detail of PVC material behavior.

State-of-the-art equipment – Precision extrusion machines and quality control systems.

Customization capability – Shapes, finishes, sizes, and properties tailored to your needs.

Strict quality assurance – Lampshades tested for optical, thermal, and structural performance.

Competitive pricing – Cost-efficient solutions without compromising on quality.

Global supply – Trusted by lighting manufacturers worldwide.

Partnering with SW means getting PVC lampshades that are reliable, consistent, and perfectly matched to LED lighting applications.

6. Applications of PVC Lampshades in LED Lighting

PVC lampshades are widely used in different LED products:

Residential lighting: table lamps, floor lamps, pendant lights.

Commercial lighting: office fixtures, retail lighting, display illumination.

Outdoor lighting: garden lights, decorative wall lamps, waterproof LED covers.

Industrial use: task lamps, machine lights with protective shades.

Decorative designs: colorful PVC lampshades for events, hotels, or hospitality interiors.

This versatility makes PVC lampshades one of the most practical choices for modern lighting design.

choosing the right PVC lampshade factory

The growing popularity of LED lighting has created new demands for lampshades that are durable, attractive, and cost-efficient. PVC lampshades, produced through the extrusion process, provide the perfect solution.

From material preparation and extrusion to custom finishes and advanced performance options, PVC lampshades offer unmatched flexibility for both functional and decorative LED applications.

At SW, as a leading PVC lampshade manufacturer, we specialize in delivering tailored solutions for global lighting brands. Whether you need standard extruded lampshades or fully custom designs, we can help you achieve the perfect balance of performance, cost, and aesthetics.

By choosing the right PVC lampshade factory, you gain more than just a product — you gain a partner in your lighting innovation.

We have a PVC pipes factory of skilled engineers ready to support you in your product development journey from idea design to production.Any ideas about your product you can contact us freely,and our engineers will get back to you with a quote asap. Whatsapp +86 188 2072 7151

Who is Shuowei?

Since 2006, Shuowei is a professional extrusion profiles factory based in Guangdong, China. There are total about 51-100 people in our office. Shuowei PVC extrusion factory is committed to the design and production of extruded profiles, such as PVC pipes, PE trunking, PVC skirting line. Since its inception, we have won the wide recognition of the market and the deep trust of customers with our ingenious design, exquisite technology and the ultimate pursuit of quality.

Are you a manufacturer or a trader?

We are a Chinese top PVC extrusion profiles manufacturer and our factory is located in Huizhou. Our factory has a 16,000㎡ production base, 5+ automated extrusion profiles production lines, an annual production capacity of 30,000 tons, and serves more than 500 customers worldwide. Welcome to visit our factory!

What is your product range?

We pecialize in the design and production of high quality extrusion profiles,such as PVC pipe, ABS extrusion, PC lampshades, PVC skirting lines, PP trunking, PE profiles…

How long does the custom development process take?

We support custom extrusion products. The usual process has 4 steps: demand confirmation → 3D design/proofing → test certification → mass production (cycle 3-8 weeks).

Do you have any international certifications?

We have passed ISO 9001, CE, RoHS, SGS and other certifications, and meet the mainstream standards of Europe, America, the Middle East and Asia