In the world of modern construction and interior decoration, wall and ceiling solutions must balance durability, aesthetics, and cost-effectiveness. Among the many materials available, PVC panels have become one of the most popular choices for architects, builders, and homeowners. Known for its versatility, affordability, and ease of installation, the PVC panel has transformed both residential and commercial spaces.

At SW, we are a professional PVC panel factory with over 20 years of extrusion and manufacturing experience. We have supplied standard and customized PVC panels for countless projects worldwide. In this blog, we will provide a detailed introduction to the PVC panel and guide you through the process of manufacturing customized PVC panels for specific requirements.

1. What is a PVC Panel?

A PVC panel is a lightweight yet strong product made from polyvinyl chloride, a thermoplastic polymer widely used in building and decorative industries. Panels are produced by an extrusion process and are designed to cover walls and ceilings, replacing traditional materials such as wood, tiles, or paint.

1.1 Key Characteristics of PVC Panels

Durability: Resistant to impact, moisture, and corrosion.

Waterproof: Non-porous surface makes it ideal for bathrooms and kitchens.

Fire Resistance: High-quality panels meet international fire safety standards.

Lightweight: Easier to transport and install compared to tiles or wood.

Design Flexibility: Available in matte, glossy, marble, or wood-grain finishes.

Cost-Effective: More affordable than natural wood or ceramic tiles.

1.2 Common Applications of PVC Panels

Residential walls and ceilings

Commercial interiors (offices, hotels, shops)

Wet areas (bathrooms, kitchens, basements)

Decorative cladding in showrooms and retail spaces

2. Why Choose PVC Panels Over Other Materials?

Compared with wood, tiles, or gypsum, the PVC panel offers several unique advantages:

Moisture Resistance: Unlike wood or MDF, PVC does not swell or rot.

Low Maintenance: Easy to clean with just a damp cloth.

Hygienic Surface: Resistant to mold and mildew.

Faster Installation: Interlocking designs reduce labor time.

Customizable: PVC extrusion allows for tailored sizes, shapes, and finishes.

3. Standard PVC Panel Specifications

At SW, our PVC panels are available in a wide range of standard specifications:

Width: 100 mm, 200 mm, 250 mm, 300 mm, 400 mm

Thickness: 5 mm, 7 mm, 8 mm, 10 mm, 12 mm

Length: Standard 2.6 m, 2.9 m, 3.0 m, or customized

Surface Options: Printing, lamination, high-gloss, matte, embossed, or UV-coating

Edge Type: Tongue-and-groove interlocking design for seamless installation

4. The Manufacturing Process of PVC Panels

The production of a PVC panel requires precise extrusion technology and strict quality control. Below is a step-by-step guide to the process:

4.1 Raw Material Preparation

PVC Resin: The base polymer used to make panels.

Additives: Stabilizers, plasticizers, lubricants, and pigments are added to improve durability, flexibility, and color.

Mixing: Materials are blended in a high-speed mixer to create a uniform compound.

4.2 Extrusion Process

The compound is fed into an extruder machine.

High temperature and pressure melt the material.

The molten PVC is shaped through a mold (die) that determines the panel profile.

4.3 Cooling and Calibration

The extruded panel passes through a water cooling system.

A calibration unit ensures accurate dimensions and surface smoothness.

4.4 Surface Treatment

Depending on customer requirements, panels can be finished with:

Printing (wood grain, marble, stone patterns)

Lamination (foil for glossy or matte finish)

UV Coating (for enhanced scratch and fade resistance)

4.5 Cutting and Sizing

Panels are cut to standard or custom lengths (e.g., 2.6 m, 2.9 m, 5.8 m).

4.6 Packaging

Finished panels are wrapped in protective film, stacked, and packed for shipment.

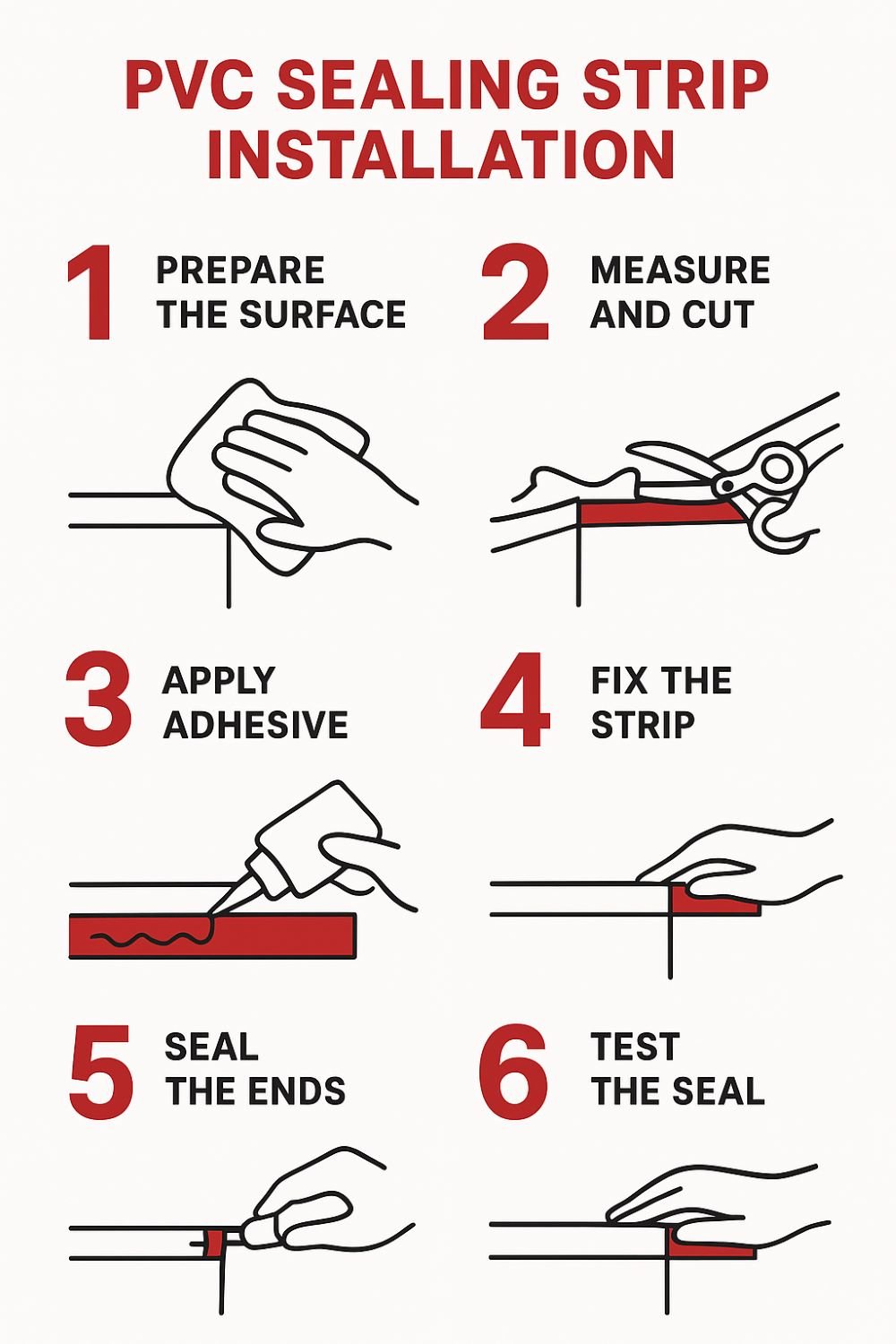

A picture shows how to customize PVC panels

5. How Customized PVC Panels Are Made

Customization is one of the greatest strengths of PVC panel production. At SW, we provide OEM and ODM services to match our clients’ project needs.

5.1 Customized Dimensions

Panels can be extruded in unique widths and thicknesses.

Lengths can be adjusted for regional market preferences (e.g., 2.95 m for Europe, 5.8 m for containers).

5.2 Customized Colors and Designs

We can match Pantone colors for corporate branding.

Custom printed patterns (wood, marble, stone, floral, metallic).

Special embossing for textured finishes.

5.3 Customized Surface Finishes

High Gloss: For modern interiors.

Matte: For a natural look.

UV Coating: For outdoor or sunlight-prone areas.

5.4 Customized Fire-Retardant or UV-Resistant Panels

For hospitals, schools, or high-safety areas, fire-rated formulations are available.

For outdoor applications, UV-stabilized PVC panels ensure long life.

5.5 Branding Options

Panels can include your brand logo on packaging or embossing.

OEM labeling helps distributors sell under their own names.

6. Quality Control in PVC Panel Manufacturing

To ensure every PVC panel meets international standards, SW follows strict quality assurance steps:

Raw Material Inspection

Extrusion Monitoring (temperature, pressure, speed)

Surface Testing (adhesion, scratch resistance)

Dimensional Accuracy (thickness, width, interlock precision)

Final Inspection before packaging

7. Applications of Customized PVC Panels

Customized PVC panels are widely used across industries:

Residential Projects: Living rooms, bedrooms, bathrooms, kitchens.

Commercial Projects: Office partitions, retail stores, hotels.

Public Infrastructure: Schools, hospitals, airports.

Industrial Use: Cleanrooms, factories, laboratories.

8. Why Choose SW as Your PVC Panel Factory?

With over 20 years of professional manufacturing experience, SW offers:

Complete Product Range: From standard PVC panels to custom-designed solutions.

OEM/ODM Services: We design and produce according to your market needs.

Advanced Technology: State-of-the-art extrusion equipment ensures precision.

Strict Quality Control: Every panel meets international standards.

Global Export Experience: Serving customers in Asia, Europe, Africa, and America.

Competitive Pricing: Factory-direct supply guarantees cost-effectiveness.

SW focus on PVC panel

The PVC panel is a versatile, durable, and affordable solution for modern construction and interior decoration. With benefits such as moisture resistance, fire safety, and design flexibility, PVC panels have become an essential material in residential, commercial, and industrial projects.

At SW, we not only manufacture high-quality standard PVC panels but also provide complete customization options. From dimensions and colors to finishes and branding, we deliver PVC panels tailored to meet the needs of global customers.

If you are looking for a reliable PVC panel factory to support your projects or brand, SW is your trusted partner with two decades of expertise.

We have a PVC panels factory of skilled engineers ready to support you in your product development journey from idea design to production.Any ideas about your product you can contact us freely,and our engineers will get back to you with a quote asap. Whatsapp +86 188 2072 7151

Who is Shuowei?

Since 2006, Shuowei is a professional extrusion profiles factory based in Guangdong, China. There are total about 51-100 people in our office. Shuowei PVC extrusion factory is committed to the design and production of extruded profiles, such as PVC pipes, PE trunking, PVC skirting line. Since its inception, we have won the wide recognition of the market and the deep trust of customers with our ingenious design, exquisite technology and the ultimate pursuit of quality.

Are you a manufacturer or a trader?

We are a Chinese top PVC extrusion profiles manufacturer and our factory is located in Huizhou. Our factory has a 16,000㎡ production base, 5+ automated extrusion profiles production lines, an annual production capacity of 30,000 tons, and serves more than 500 customers worldwide. Welcome to visit our factory!

What is your product range?

We pecialize in the design and production of high quality extrusion profiles,such as PVC pipe, ABS extrusion, PC lampshades, PVC skirting lines, PP trunking, PE profiles…

How long does the custom development process take?

We support custom extrusion products. The usual process has 4 steps: demand confirmation → 3D design/proofing → test certification → mass production (cycle 3-8 weeks).

Do you have any international certifications?

We have passed ISO 9001, CE, RoHS, SGS and other certifications, and meet the mainstream standards of Europe, America, the Middle East and Asia