In an industry where micron-level tolerances decide market success, choosing a plastic extrusion factory partner isn’t about finding suppliers – it’s about securing engineering allies. At Shuowei, we’ve refined our service architecture over 20 years and 3,000+ global projects to transform complex profile challenges into competitive advantages. Here’s why manufacturers trust our rigorously engineered process.

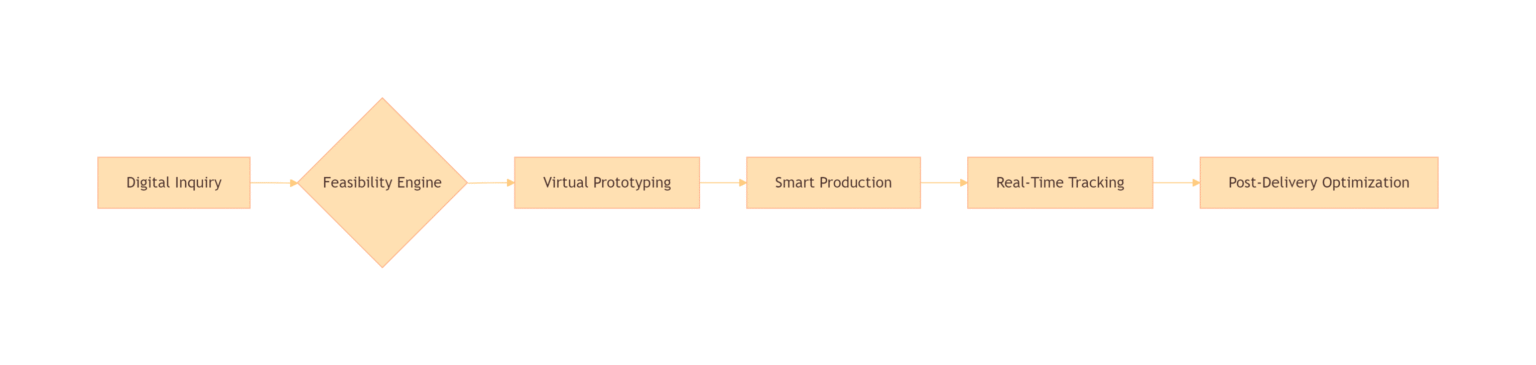

SW plastic extrusion factory Core Differentiator: Integrated Service Ecosystem

Unlike conventional factories, Shuowei merges robotics-driven precision, materials science, and digital transparency into a seamless workflow. Our ISO 9001/IATF 16949-certified process eliminates 92% of traditional friction points.

Phase 1: find SW plastic extrusion factory

Goal: Transform vague requirements into engineered solutions

Step 1: Intelligent Project Intake

- Online Configurator: Upload CAD files or sketch requirements via our AI-powered platform

- Instant DFM Feedback: Automated analysis of:

- Wall thickness uniformity

- Undercut manufacturability

- Material-flow simulations

Output: Preliminary Technical Report within 4 business hours

Step 2: Cross-Functional Scoping

Your dedicated team:

- Applications Engineer: Material selection (e.g., UV-stabilized PP for outdoor use)

- Process Specialist: Tolerance mapping (±0.05mm achievable?)

- Supply Chain Analyst: Logistics optimization (e.g., sea/air freight cost modeling)

Output: Project Charter with 18-point risk assessment

Client Case: German automotive supplier reduced development costs by 37% through our material-substitution advisory (PA66 → PPA for under-hood components).

Phase 2: Virtual Engineering & Prototyping (3-15 Days)

Goal: Validate performance before tooling investment

Critical Actions:

3D Modeling & FEA

- SolidWorks topology optimization (e.g., 32% weight reduction on cable ducting)

- ANSYS mold flow analysis (predicting weld lines/sink marks)

Digital Twin Creation

Simulate:- Thermal cycling (-40°C to 150°C)

- Structural loading (ISO 527 tensile tests)

- Chemical resistance (IEC 60695-11-10)

Rapid Functional Prototyping

Method Lead Time Accuracy Best For 3D Printing 2-3 days ±0.2mm Form/fit checks CNC Machining 5-7 days ±0.05mm Mechanical validation Short-Run Extrusion 10-15 days Production-grade Field testing

Phase 3: Tooling & Process Validation (15-30 Days)

Goal: Achieve production-ready tooling with zero surprises

Our Toolroom Capabilities:

- Modular Die Systems: Quick-change inserts (45min changeover)

- Multi-Layer Flow Simulation: For coextrusion barriers

- Surface Texturing: EDM finishing to Ra 0.1μm

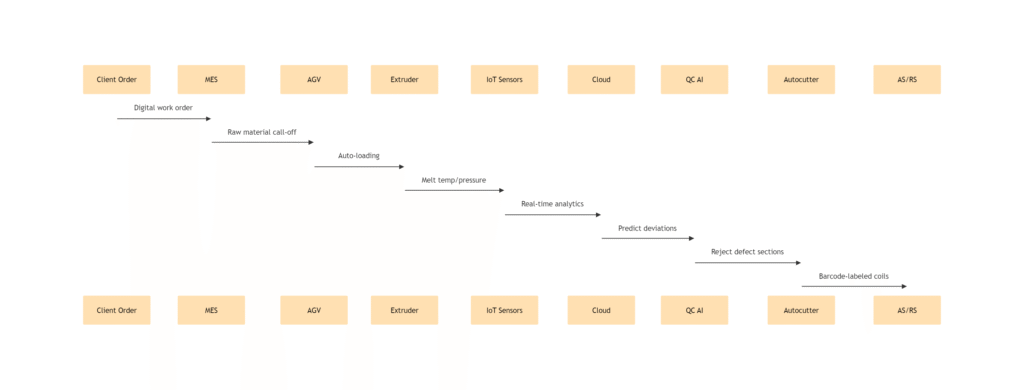

Phase 4: Industry 4.0 Production (Lead Time: 15-60 Days)

Smart Factory Workflow:

Precision Control Highlights:

- Auto-Adaptive Extruders: Compensate for material viscosity shifts

- Laser Micrometers: 100% dimensional scanning at 60m/min

- Blockchain Traceability: Scan QR code for full process history

Capacity Scale:

- 50-1,200 kg/hour per line

- 30,000+ tons annual output

Phase 5: Logistics & Global Compliance (Seamless Export)

Our Integrated Logistics:

| Stage | Technology | Client Benefits |

|---|---|---|

| Packaging | Auto-stretch wrapping + Edge protectors | 99.98% damage-free transit |

| Documentation | AI-powered paperwork generation | 1-hour commercial invoice processing |

| Regulatory | Embedded compliance engine | Automatic RoHS/REACH/FDA updates |

| Shipment Tracking | Live container monitoring | GPS temperature/humidity alerts |

Global Footprint Proof:

- 48-hour delivery window to EU industrial zones

- Pre-cleared channels in 12 ports (e.g., Rotterdam, LA/LB)

Phase 6: SW plastic extrusion factory Aftercare & Continuous Improvement

Post-Delivery Services:

- Performance Dashboard: Monitor your profiles’ field performance

- Preventive Maintenance Alerts: “Replace sealant in 3 months” notifications

- Material Recycling Program: Closed-loop regrind service

Why Our Process Beats Industry Benchmarks

| Metric | Industry Average | Shuowei Performance |

|---|---|---|

| RFQ → Quote turnaround | 5-7 days | <24 hours |

| Prototype accuracy | ±0.15mm | ±0.05mm |

| On-time delivery | 85% | 98.7% |

| Post-shipment issues | 3.2% | 0.8% |

Client Transformation: Siemens Building Tech

Challenge:

Fire-resistant cable conduits requiring:

- UL94 V-0 + IEC 60332-3

- Color consistency ΔE<1 across batches

- 48-hour emergency replenishment

Our Process Execution:

- Material Innovation: Developed TiO2-stabilized PVC formulation

- Digital Twin: Predicted color drift under humidity swings

- Distributed Manufacturing: Produced simultaneously in China/Mexico plants

- Smart Inventory: AI-driven safety stock at Chicago hub

Results:

- $2.3M saved in expedited freight costs

- Zero project delays over 3-year partnership

Experience Process Transparency

Shuowei isn’t just a plastic extrusion factory – it’s your engineering command center. We invite you to:

- [Run a Virtual Capability Assessment] – Upload your drawing for instant DFM analysis

- [Download Service Blueprint] – 28-page process playbook with compliance checklists

- [Book Live Factory Tour] – See Industry 4.0 extrusion via 360° VR

Process Guarantee:

“If any service milestone misses agreed specs, we comp your next production run.”

Elevate your extrusion projects from transactional to transformational.

Contact process engineers: lucy@dgsw888.com | +86-13509821151

We have a plastic extrusion factory of skilled engineers ready to support you in your product development journey from idea design to production.Any ideas about your product you can contact us freely,and our engineers will get back to you with a quote asap.Whatsapp +86 13509821151

Who is Shuowei?

Since 2006, Shuowei is a professional extrusion profiles factory based in Guangdong, China. There are total about 51-100 people in our office. Shuowei PVC extrusion factory is committed to the design and production of extruded profiles, such as PVC pipes, PE trunking, PVC skirting line. Since its inception, we have won the wide recognition of the market and the deep trust of customers with our ingenious design, exquisite technology and the ultimate pursuit of quality.

Are you a manufacturer or a trader?

We are a Chinese top PVC extrusion profiles manufacturer and our factory is located in Huizhou. Our factory has a 16,000㎡ production base, 5+ automated extrusion profiles production lines, an annual production capacity of 30,000 tons, and serves more than 500 customers worldwide. Welcome to visit our factory!

What is your product range?

We pecialize in the design and production of high quality extrusion profiles,such as PVC pipe, ABS extrusion, PC lampshades, PVC skirting lines, PP trunking, PE profiles…

How long does the custom development process take?

We support custom extrusion products. The usual process has 4 steps: demand confirmation → 3D design/proofing → test certification → mass production (cycle 3-8 weeks).

Do you have any international certifications?

We have passed ISO 9001, CE, RoHS, SGS and other certifications, and meet the mainstream standards of Europe, America, the Middle East and Asia