“PVC extrusion profiles are widely used in daily life due to their excellent performance and better price. There are many PVC extrusion profile manufacturers in China. SW Company enjoys the trust of customers because of its superior manufacturing capabilities and quality assurance. Let’s learn about the powerful OEM PVC extrusion profile manufacturing capability of SW”

1.Core Advantages of PVC extrusion profiles Manufacturing

“We transform polymer molecules into perfectly engineered profiles — with speed, precision, and relentless consistency.”–Jack Wong–CEO

Manufacturing Capabilities Overview

| Capability | Technical Highlights | Competitive Edge |

|---|---|---|

| Automation Level | Industry 4.0-enabled production lines | 24/7 unmanned operation achievable |

| Dimensional Control | ±0.05mm laser-guided calibration | 3x tighter than ISO 3302-1 |

| Material Versatility | PVC/PP/PE/ABS/PA/PPO/PMMA, etc. | 200+ compound formulations |

| Output Scalability | 50 kg/hr to 1,200 kg/hr per line | From prototyping to mass production |

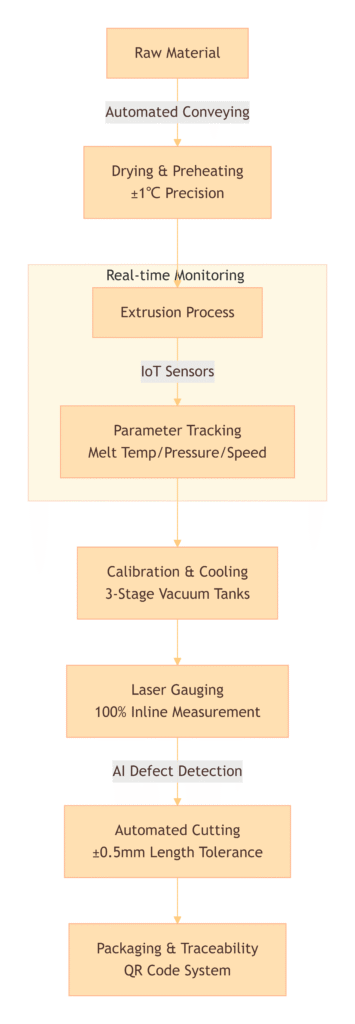

2.PVC extrusion profiles Smart Production Flow

Key Control Points:

✅ Melt Stability: ±1.5% pressure fluctuation (vs. industry avg. ±5%)

✅ Cooling Efficiency: 0.5℃/mm gradient control to prevent warpage

✅ Traceability: Full data logging per meter of extrusion

3.Cutting-Edge Production Facilities

3.1. Advanced Extrusion Lines

- 22x Battenfeld Cologne extruders (Germany)

- Screw diameters: 45mm-120mm

- Dedicated lines for:

- Multi-coextrusion (up to 5 layers)

- Micro-profiles (min. wall thickness 0.3mm)

3.2. Industry-Leading QC Lab

| Equipment | Function | Standard Compliance |

|---|---|---|

| Instron 5967 Universal Tester | Tensile/Impact/Flexural Tests | ASTM D638/D790/ISO 180 |

| Atlas Xenotest 440 | UV Aging Simulation | ISO 4892-2/AATCC TM16 |

| Zwick Roell Melt Flow Indexer | Material Rheology Analysis | ISO 1133 |

4.Why Global Leaders Trust SW PVC extrusion profiles

Case 1: Automotive Sealant Profiles for Continental AG

- Challenge: 0.15mm tolerance for 8m continuous extrusion

- Solution: AI-driven thermal compensation + servo pullers

- Result: 99.2% batch acceptance rate (vs. contract requirement 97%)

Case 2: Medical-Grade Tubing for Philips Healthcare

- Requirement: ISO Class 7 cleanroom production

- Implementation: Dedicated negative-pressure extrusion line

- Validation: 0 particle count >0.5μm per ft³

5.Sustainability-Driven Manufacturing

Green Initiatives Integrated into Production:

- ♻️ Material Recycling: 100% in-house regrind utilization

- 🌱 Energy Recovery: 35% waste heat reused in pre-drying

- 📉 Zero Wastewater: Closed-loop cooling system

Ready to Experience Precision Manufacturing?

[Request Plant Virtual Tour] | [Download Technical Capability Brochure]

We have a PVC extrusion profiles factory of skilled engineers ready to support you in your product development journey from idea design to production.Any ideas about your product you can contact us freely,and our engineers will get back to you with a quote asap.Whatsapp +86 13509821151

Who is Shuowei?

Since 2006, Shuowei is a professional extrusion profiles factory based in Guangdong, China. There are total about 51-100 people in our office. Shuowei PVC extrusion factory is committed to the design and production of extruded profiles, such as PVC pipes, PE trunking, PVC skirting line. Since its inception, we have won the wide recognition of the market and the deep trust of customers with our ingenious design, exquisite technology and the ultimate pursuit of quality.

Are you a manufacturer or a trader?

We are a Chinese top PVC extrusion profiles manufacturer and our factory is located in Huizhou. Our factory has a 16,000㎡ production base, 5+ automated extrusion profiles production lines, an annual production capacity of 30,000 tons, and serves more than 500 customers worldwide. Welcome to visit our factory!

What is your product range?

We pecialize in the design and production of high quality extrusion profiles,such as PVC pipe, ABS extrusion, PC lampshades, PVC skirting lines, PP trunking, PE profiles…

How long does the custom development process take?

We support custom extrusion products. The usual process has 4 steps: demand confirmation → 3D design/proofing → test certification → mass production (cycle 3-8 weeks).

Do you have any international certifications?

We have passed ISO 9001, CE, RoHS, SGS and other certifications, and meet the mainstream standards of Europe, America, the Middle East and Asia