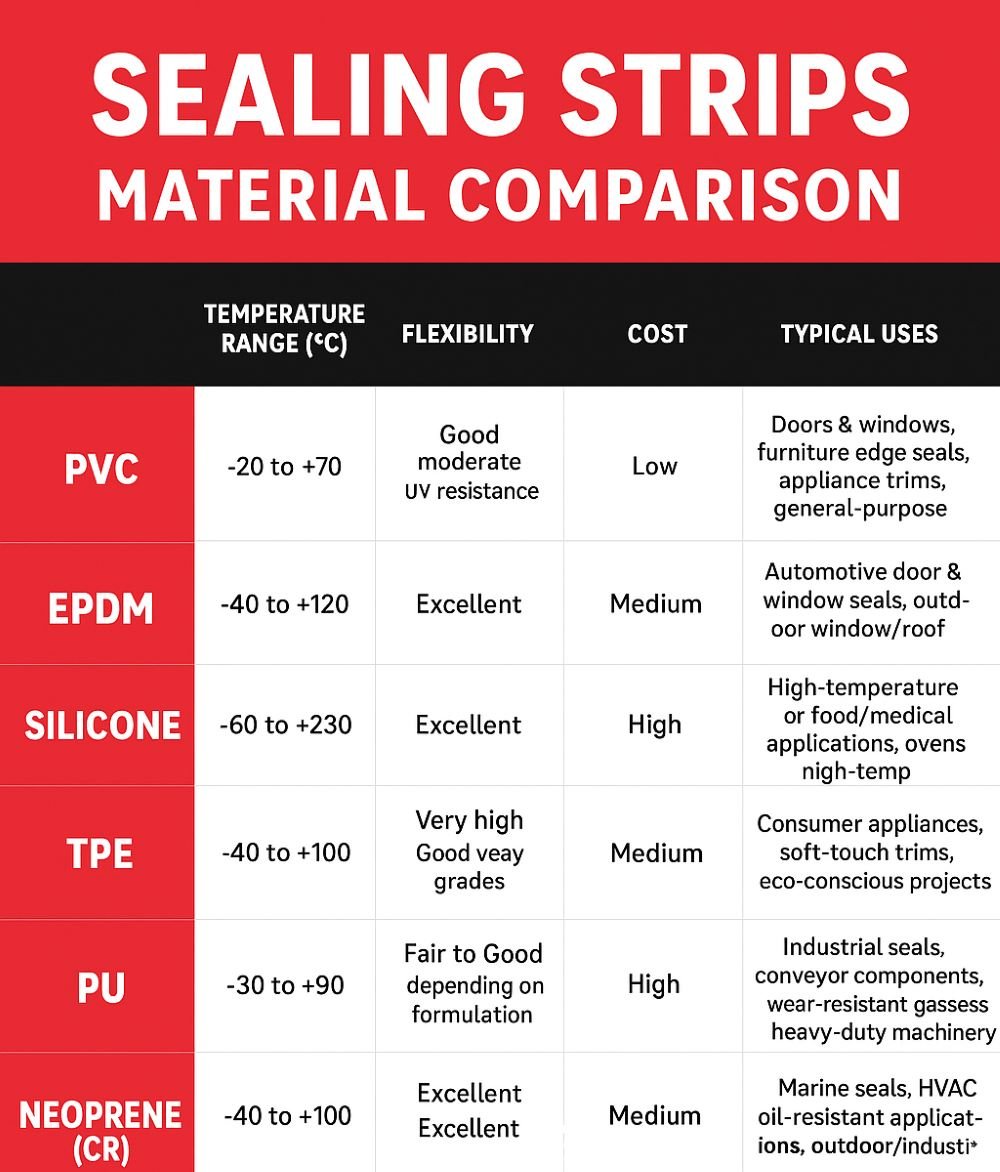

In industries ranging from construction and automotive to appliances and electronics, PVC sealing strip is essential components that provide airtight and watertight seals. They help prevent dust, moisture, noise, and vibration from passing through gaps in doors, windows, and equipment assemblies. Over the past decades, PVC sealing strips have become one of the most versatile and cost-effective sealing solutions worldwide.

At SW, we specialize in the extrusion and customization of PVC sealing strips, with over 20 years of manufacturing experience. Our goal is to help businesses design and produce the ideal sealing solutions tailored to their exact needs. This article explores every stage of how PVC sealing strips are produced, how customization works, and what factors to consider for performance and longevity.

What is PVC Sealing Strip?

PVC sealing strip is extruded flexible plastic profiles designed to provide sealing and insulation between two surfaces. Made primarily from polyvinyl chloride (PVC), they are known for their excellent flexibility, chemical resistance, and durability.

PVC sealing strips can be solid, hollow, or co-extruded, and can incorporate additional features like adhesive backing, decorative coloring, or reinforced ribs. They are commonly used in:

-

Doors and windows (to block air or water leakage)

-

Refrigerators and freezers (for thermal insulation)

-

Automobiles (for dustproof and vibration reduction)

-

Construction (for expansion joints and glazing systems)

-

Appliances and cabinets (for soundproofing and dust prevention)

Advantages of PVC Sealing Strip

PVC sealing strip has several advantages that make them a preferred choice for both manufacturers and consumers:

-

Durability: Resistant to weathering, aging, and most chemicals.

-

Flexibility: Excellent bendability even at low temperatures.

-

Water and Dust Resistance: Prevents leakage and contamination.

-

Ease of Processing: Easily extruded into different profiles and shapes.

-

Customizability: Color, hardness, size, and cross-section can all be tailored.

-

Cost-Effectiveness: PVC is affordable and easy to produce in bulk.

Step-by-Step Process: How PVC Sealing Strip is Manufactured

1. Raw Material Selection

The first step in producing PVC sealing strip is selecting the right formulation of polyvinyl chloride resin, combined with plasticizers, stabilizers, and additives.

-

PVC Resin: Base material for the strip.

-

Plasticizers: Enhance flexibility and elasticity.

-

Stabilizers: Protect against heat degradation during extrusion.

-

Colorants: Provide aesthetic customization (e.g., black, gray, white).

-

Fillers and Modifiers: Adjust hardness and tensile strength.

The exact material blend depends on where the PVC sealing strips will be used—for instance, higher UV stabilizers for outdoor use or food-grade additives for refrigerator applications.

2. Mixing and Compounding

The chosen raw materials are precisely weighed and mixed in a high-speed mixer. The compound must be uniform to ensure consistent color and mechanical performance.

-

Hot Mixing: Ingredients are combined and heated to disperse additives evenly.

-

Cooling: The mixture is cooled to room temperature before extrusion.

-

Pelletizing: The compound is sometimes converted into small granules for feeding consistency.

At this stage, quality control technicians check color uniformity, melt flow rate, and density.

3. Extrusion Process

The extrusion process transforms raw PVC material into continuous sealing profiles. It involves several key steps:

a. Feeding and Melting

PVC granules are fed into an extruder machine, where rotating screws push the material forward through heated barrels. The PVC melts into a uniform, viscous state.

b. Shaping Through Die

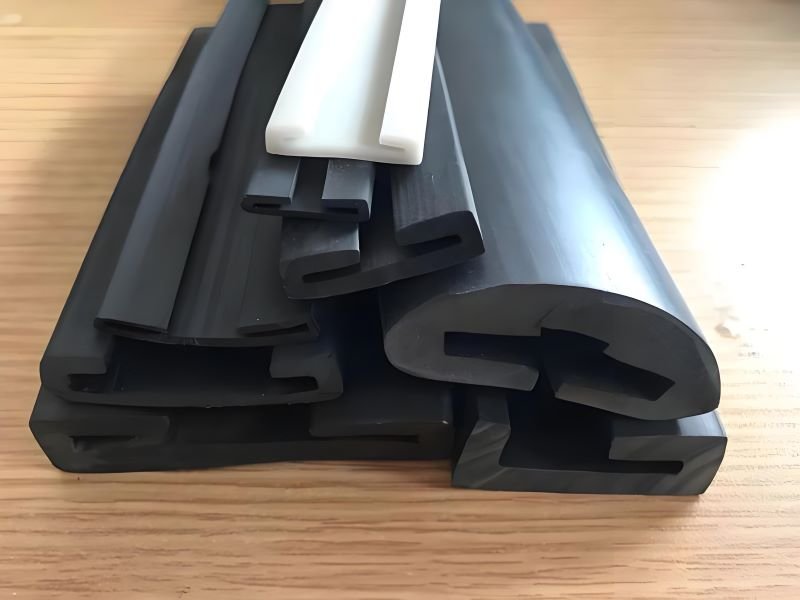

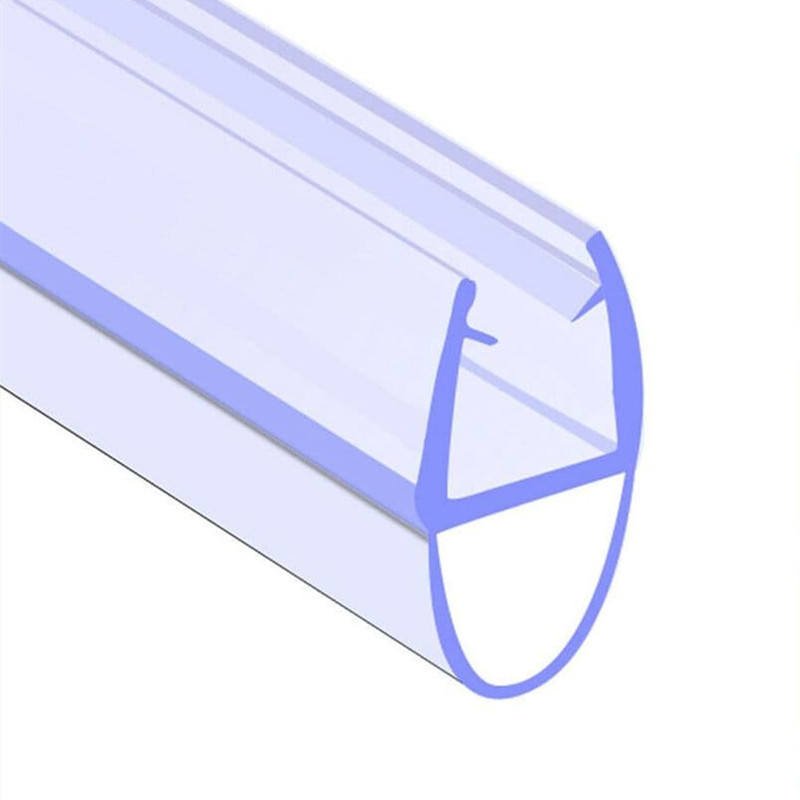

The molten PVC passes through a custom-designed extrusion die, which determines the shape of the sealing strip—whether it’s a simple D-shape, P-shape, U-channel, or complex co-extrusion.

SW uses precision-engineered dies designed in-house for superior accuracy and dimensional control.

c. Cooling and Calibration

After extrusion, the hot profile passes through a calibration and cooling system—usually water baths or air cooling channels. The goal is to maintain dimensional stability and prevent deformation.

d. Haul-off and Cutting

The cooled strip is pulled continuously by haul-off rollers and then cut to the desired length—either standard 2-meter pieces or customized rolls.

4. Surface Treatment and Finishing

Depending on customer requirements, PVC sealing strips may receive additional finishing steps:

-

Embossing: Adds surface texture for grip or aesthetics.

-

Printing: For branding or measurement markings.

-

Co-extrusion: Combines two PVC materials (e.g., soft + rigid) for improved sealing.

-

Self-Adhesive Backing: Adds peel-and-stick convenience for easy installation.

These finishing touches enhance performance and make installation faster for end users.

5. Quality Control and Testing

Quality is the heart of PVC sealing strips manufacturing. At SW, we perform multiple quality checks throughout the process:

| Test Type | Description | Purpose |

|---|---|---|

| Dimensional Accuracy | Verifies profile width, thickness, and tolerances | Ensures correct fit in assembly |

| Hardness Test | Measures Shore A hardness | Confirms flexibility |

| Aging & UV Resistance | Simulates outdoor exposure | Predicts long-term durability |

| Compression Set Test | Measures recovery after deformation | Ensures long-lasting sealing |

| Tensile Strength Test | Evaluates pull and tear resistance | Checks material integrity |

6. Customization and Design

One of the greatest advantages of PVC sealing strips is their customizability. At SW, our engineering team collaborates with customers to design and produce sealing strips tailored to their products.

Common customization options include:

-

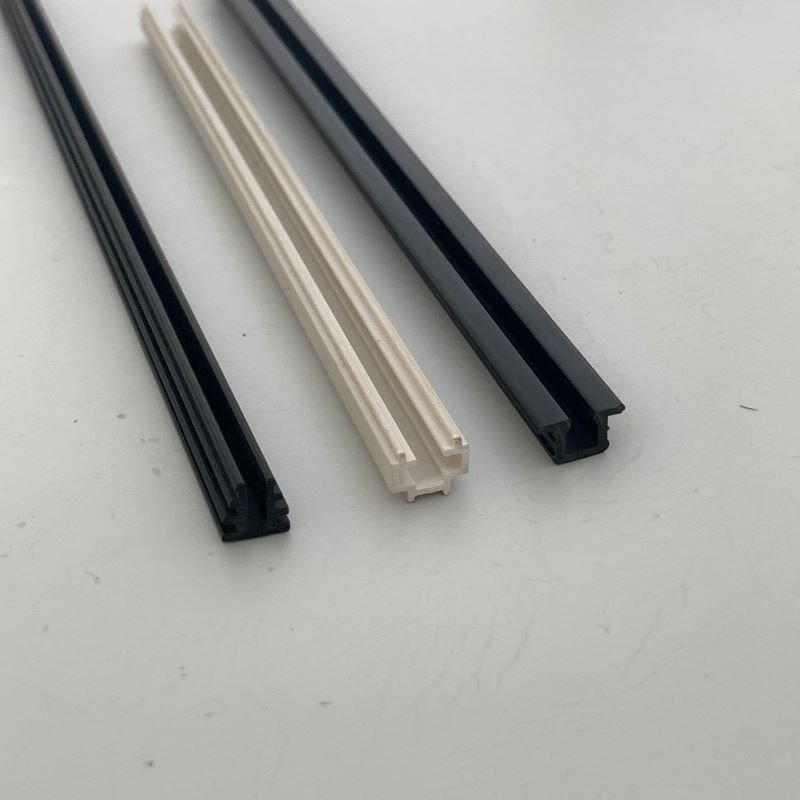

Shape/Profile: D, E, P, U, L, H, or unique shapes.

-

Color: Black, white, gray, transparent, or any RAL color.

-

Hardness: From Shore A 50 (soft) to 90 (hard).

-

Co-extrusion: Combining soft and rigid PVC materials.

-

Adhesive Type: Standard, strong, or removable.

-

Special Properties: Flame retardant, UV-resistant, food-safe, anti-bacterial.

Through CAD design and 3D simulation, SW ensures each custom profile meets specific functional and aesthetic requirements.

Applications of PVC Sealing Strip

PVC sealing strip is versatile and used across multiple industries:

| Application | Function | Typical Product Example |

|---|---|---|

| Windows & Doors | Weatherproofing, noise insulation | Architectural seals |

| Automotive | Dustproofing, vibration reduction | Door & trunk gaskets |

| Refrigeration | Thermal insulation | Refrigerator/freezer door seals |

| Furniture | Edge protection | Cabinet or glass door trims |

| Construction | Expansion joints, waterproofing | Glazing gaskets |

| Electrical Enclosures | Dust & moisture prevention | Control panel seals |

Usage and Installation Tips

To maximize the performance of PVC sealing strip, follow these installation and usage recommendations:

-

Clean the Surface: Ensure no oil, dust, or debris remains before applying the strip.

-

Measure Accurately: Cut strips slightly longer than the gap for full compression.

-

Apply Even Pressure: Press firmly along the length to secure adhesion.

-

Avoid Overstretching: PVC has elastic memory; stretching can cause shrinkage later.

-

Regular Maintenance: Clean with mild soap and inspect for aging annually.

Why Choose SW as Your PVC Sealing Strip Partner

With over 20 years of extrusion experience, SW has become a trusted PVC sealing strip factory for global brands. Here’s why clients choose us:

-

Custom Design Expertise: From concept to production, we develop tailor-made sealing profiles.

-

Advanced Extrusion Technology: Equipped with high-precision extrusion and co-extrusion lines.

-

Strict Quality Control: ISO-certified processes ensure product reliability.

-

Flexible MOQ and OEM Support: Ideal for both startups and large-scale manufacturers.

-

Competitive Pricing: High quality at factory-direct prices.

Our philosophy is simple: “Precision in every profile, performance in every seal.”

Sustainability and Environmental Considerations

SW is committed to sustainable manufacturing. Our PVC sealing strip is made from eco-friendly, recyclable compounds, and our production lines are optimized to reduce waste and energy consumption.

We also offer phthalate-free and RoHS-compliant materials, ensuring safety and regulatory compliance for international markets.

PVC sealing strip is indispensable

PVC sealing strip is indispensable for modern construction, manufacturing, and consumer products. Their adaptability, cost-effectiveness, and durability make them an ideal choice for sealing applications across industries.

Whether you require custom profiles, co-extruded sealing solutions, or mass production, SW provides professional design, engineering, and manufacturing support.

As a leading PVC sealing strips factory, we bring together 20 years of expertise, precision extrusion technology, and deep knowledge of material science — delivering products that perform reliably in real-world conditions.

We have a PVC pipes factory of skilled engineers ready to support you in your product development journey from idea design to production.Any ideas about your product you can contact us freely,and our engineers will get back to you with a quote asap. Whatsapp +86 188 2072 7151

Who is Shuowei?

Since 2006, Shuowei is a professional extrusion profiles factory based in Guangdong, China. There are total about 51-100 people in our office. Shuowei PVC extrusion factory is committed to the design and production of extruded profiles, such as PVC pipes, PE trunking, PVC skirting line. Since its inception, we have won the wide recognition of the market and the deep trust of customers with our ingenious design, exquisite technology and the ultimate pursuit of quality.

Are you a manufacturer or a trader?

We are a Chinese top PVC extrusion profiles manufacturer and our factory is located in Huizhou. Our factory has a 16,000㎡ production base, 5+ automated extrusion profiles production lines, an annual production capacity of 30,000 tons, and serves more than 500 customers worldwide. Welcome to visit our factory!

What is your product range?

We pecialize in the design and production of high quality extrusion profiles,such as PVC pipe, ABS extrusion, PC lampshades, PVC skirting lines, PP trunking, PE profiles…

How long does the custom development process take?

We support custom extrusion products. The usual process has 4 steps: demand confirmation → 3D design/proofing → test certification → mass production (cycle 3-8 weeks).

Do you have any international certifications?

We have passed ISO 9001, CE, RoHS, SGS and other certifications, and meet the mainstream standards of Europe, America, the Middle East and Asia