In modern manufacturing, construction, and automotive engineering, sealing strips play a critical role in ensuring airtight, watertight, and dustproof performance. Whether installed in doors, windows, machinery, or vehicles, sealing strips are indispensable components that protect against environmental elements, vibration, and noise.

At SW, a professional plastic extrusion sealing strip factory with over 20 years of manufacturing experience, we specialize in the production of PVC sealing strips and other customized sealing solutions. Understanding the differences between sealing strip materials is crucial for choosing the right product for your application — balancing performance, durability, and cost.

This comprehensive guide explores the most common sealing strip materials, their features, advantages, and ideal applications, helping you make informed decisions when sourcing or designing your next project.

1. What Are Sealing Strips?

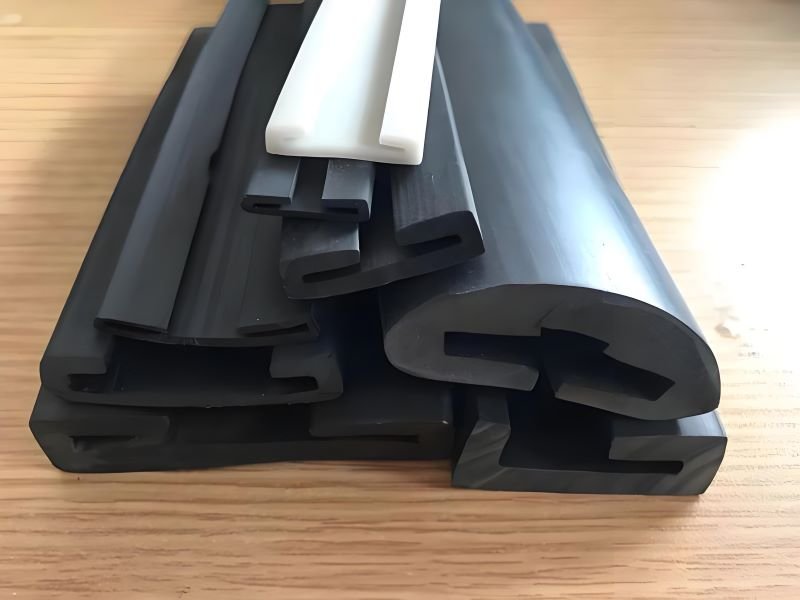

A sealing strip is a flexible material extruded into various shapes (such as U, T, P, or bulb profiles) and installed between two surfaces to prevent the passage of air, water, dust, and vibration.

These strips can be made from PVC, EPDM rubber, silicone, TPE, or polyurethane, among others, depending on the performance requirements of the application.

Primary Functions of Sealing Strips

-

Sealing: Prevents leaks and environmental ingress.

-

Insulation: Reduces sound and heat transmission.

-

Protection: Prevents damage caused by friction or impact.

-

Vibration Reduction: Absorbs mechanical shock and noise.

-

Aesthetic Enhancement: Provides clean, finished edges for structures and equipment.

Sealing strips are commonly used in automotive, construction, appliance, marine, and industrial applications.

2. Common Materials Used for Sealing Strips

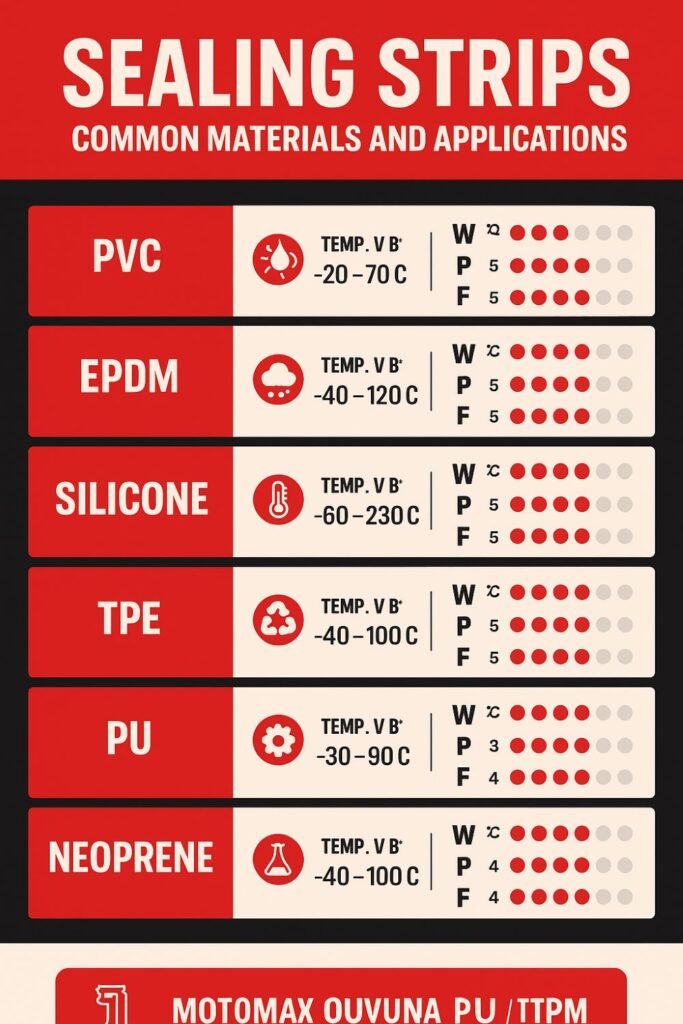

Each sealing strip material has unique mechanical and chemical properties that make it suitable for specific uses. Below is a detailed comparison of the most widely used types.

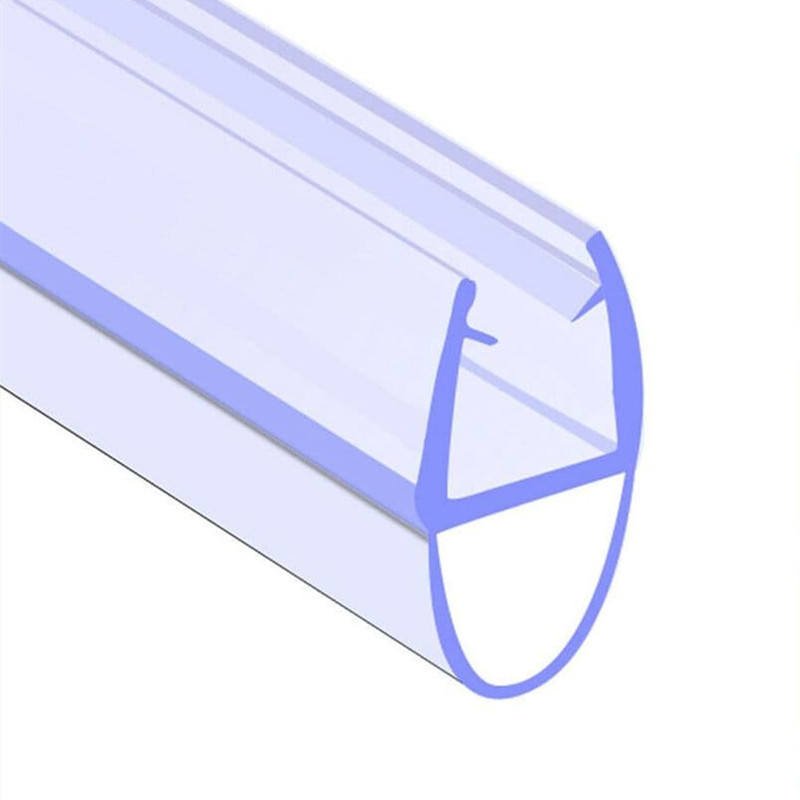

2.1. PVC Sealing Strips

PVC sealing strips are among the most popular types due to their versatility, cost-effectiveness, and ease of extrusion. At SW, we have specialized in PVC sealing strip production for over 20 years, offering custom shapes, colors, and hardness levels.

Key Features

-

Excellent weather and UV resistance

-

Waterproof and moisture-resistant

-

Available in hard and soft formulations

-

Compatible with co-extrusion for multi-layer sealing performance

-

Economical compared to rubber and silicone alternatives

Applications

-

Windows and doors

-

Automotive trims and edge seals

-

Industrial equipment

-

Refrigerators and home appliances

-

Marine hatches and boat edges

Advantages

-

Highly customizable with color and hardness options

-

Excellent dimensional stability

-

Resistant to chemical corrosion

-

Low maintenance and long lifespan

PVC sealing strips are ideal for general-purpose applications where cost, flexibility, and performance are balanced.

2.2. EPDM Sealing Strips

EPDM rubber sealing strips are widely used for demanding outdoor environments. This synthetic rubber offers exceptional durability and elasticity.

Key Features

-

Outstanding UV, ozone, and weather resistance

-

Maintains flexibility from -40°C to +120°C

-

Excellent compression set resistance

Applications

-

Car doors, trunks, and windows

-

Building façades and curtain walls

-

Industrial machinery and HVAC systems

Advantages

-

Excellent long-term sealing performance

-

Resistant to aging and environmental exposure

-

Performs well under temperature extremes

Drawback: EPDM strips can be more expensive and heavier than PVC or TPE alternatives.

2.3. Silicone Sealing Strips

Silicone sealing strips are known for their superior temperature resistance and chemical stability, often used in high-temperature or food-grade environments.

Key Features

-

Temperature resistance: -60°C to +230°C

-

FDA-approved for food and medical applications

-

Excellent compression recovery

Applications

-

Ovens, refrigerators, and kitchen appliances

-

Medical devices and laboratories

-

Electronics and lighting enclosures

Advantages

-

Non-toxic and odorless

-

Excellent thermal and electrical insulation

-

Remains flexible at extreme temperatures

Drawback: Higher production cost compared to PVC or EPDM, making it less ideal for cost-sensitive projects.

2.4. TPE Sealing Strips

TPE sealing strips combine the flexibility of rubber with the processing benefits of plastic. They are recyclable and increasingly popular as an eco-friendly alternative.

Key Features

-

Excellent elasticity and rebound

-

Lightweight and flexible

-

Recyclable and non-toxic

Applications

-

Automotive interiors

-

Electronic enclosures

-

Building joints and frames

Advantages

-

Can be co-extruded with other plastics

-

Environmentally friendly (no halogens)

-

Resistant to weather and ozone

Drawback: Slightly less durable than EPDM in harsh environments.

2.5. PU Sealing Strips

PU sealing strips offer outstanding wear resistance and elasticity, making them suitable for industrial and mechanical uses.

Key Features

-

High abrasion and tear resistance

-

Excellent impact strength

-

Resistant to oil and solvents

Applications

-

Conveyor systems

-

Industrial sealing and gaskets

-

Heavy machinery and equipment

Advantages

-

Strong and durable under load

-

Long lifespan even in abrasive conditions

-

High mechanical strength

Drawback: More expensive and sensitive to humidity compared to PVC.

2.6. Neoprene (CR) Sealing Strips

Neoprene sealing strips combine weather, oil, and chemical resistance, making them suitable for specialized industrial environments.

Key Features

-

Good resistance to oil and grease

-

Moderate UV and ozone resistance

-

Temperature range: -40°C to +100°C

Applications

-

Marine and aerospace industries

-

Industrial sealing applications

-

Electrical enclosures

Advantages

-

Multi-purpose performance

-

Resistant to flame and corrosion

-

Excellent adhesion to metals

Drawback: Higher density and cost compared to PVC and EPDM.

3. Comparison of Sealing Strip Materials

| Material | Temperature Range | Weather Resistance | Flexibility | Cost | Typical Use |

|---|---|---|---|---|---|

| PVC | -20°C to +70°C | Good | Excellent | Low | Windows, appliances, automotive |

| EPDM | -40°C to +120°C | Excellent | Excellent | Medium | Vehicles, outdoor seals |

| Silicone | -60°C to +230°C | Excellent | Excellent | High | Food, medical, high-temp |

| TPE | -40°C to +100°C | Good | Excellent | Medium | Electronics, eco projects |

| PU | -30°C to +90°C | Good | High | High | Industrial, mechanical |

| Neoprene | -40°C to +100°C | Excellent | Medium | Medium | Marine, aerospace |

From this table, PVC sealing strips stand out for their balance between cost, durability, and performance — particularly for construction, industrial, and automotive applications.

4. Choosing the Right Sealing Strip for Your Application

Selecting the best sealing strip depends on your application’s environmental conditions, performance expectations, and budget.

4.1. Consider Temperature

-

For high-temperature environments, choose silicone.

-

For general indoor/outdoor use, PVC or EPDM performs well.

4.2. Consider Chemical Exposure

-

PU and neoprene resist oil and solvents.

-

PVC provides general chemical resistance for most environments.

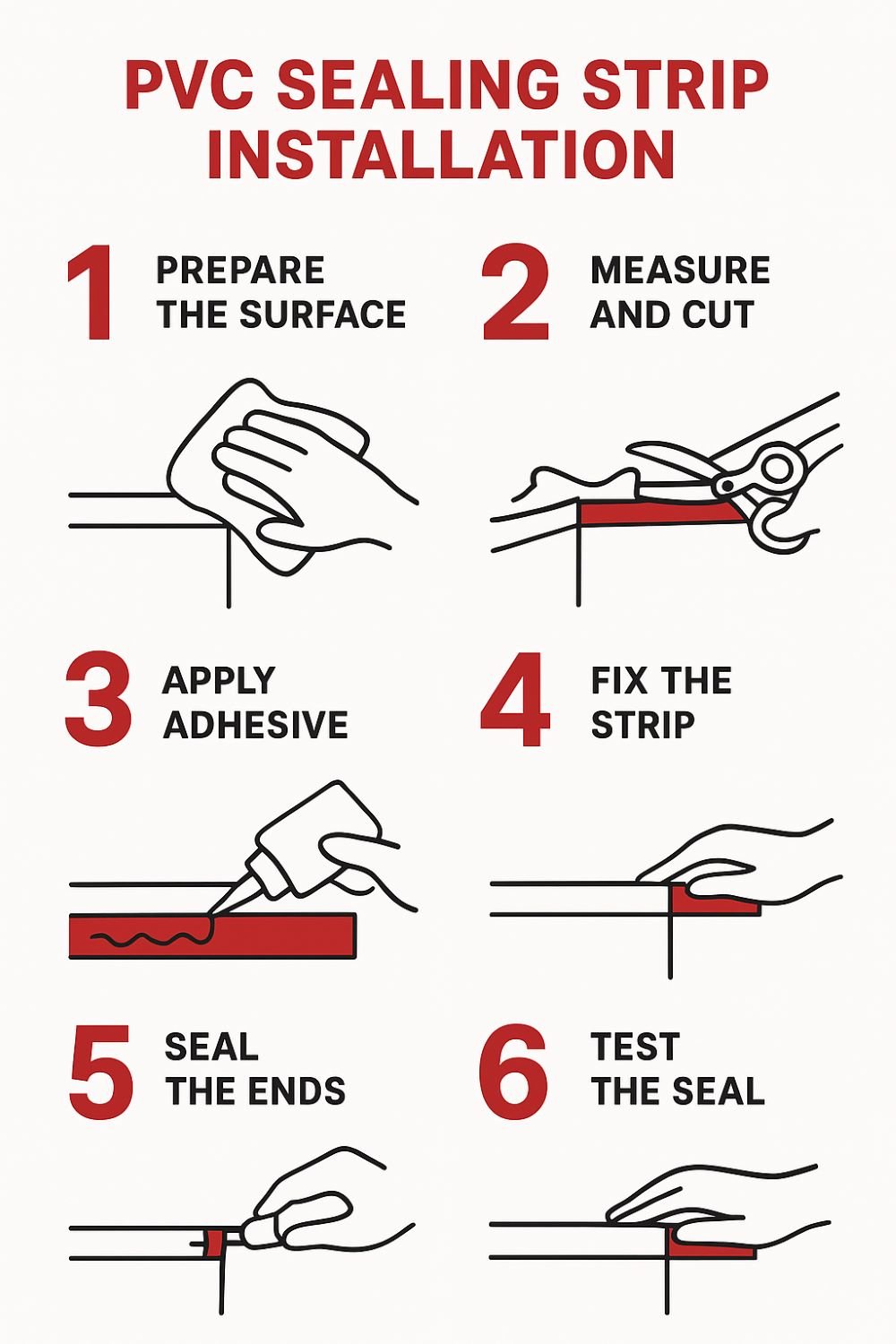

4.3. Consider Installation and Cost

-

PVC sealing strips are lightweight, affordable, and easy to install.

-

EPDM or TPE are better for heavy-duty or eco-sensitive projects.

4.4. Consider Appearance

-

PVC offers the widest color range and aesthetic flexibility for decorative sealing.

5. Customization Options for Sealing Strips

At SW, our sealing strips are fully customizable to suit different industries and design requirements.

Custom Options Include:

-

Profiles: U, P, T, D, bulb, flat, or bespoke cross-sections

-

Hardness: From 60A (soft) to 95A (rigid)

-

Colors: Black, white, gray, transparent, or custom colors

-

Materials: PVC, EPDM, TPE, PU, silicone

-

Co-extrusion: Combination of soft and hard materials for enhanced sealing

Our advanced extrusion lines enable high precision and consistent quality for every batch.

6. Real-World Applications

Case 1: Door and Window Manufacturer

A construction client switched from rubber to PVC sealing strips for cost savings and improved weather resistance, resulting in 15% lower production costs and easier installation.

Case 2: Automotive OEM

An automotive brand used co-extruded PVC-EPDM sealing strips for vehicle doors, achieving superior sound insulation and extended lifespan.

Case 3: Refrigeration Equipment

A leading appliance company used magnetic PVC sealing strips to improve refrigerator energy efficiency by 12%.

7. Why Choose SW as Your Sealing Strip Supplier

With two decades of experience, SW is one of the leading plastic extrusion sealing strip manufacturers in China, serving global customers in over 30 countries.

Our Strengths

-

20+ years of professional extrusion experience

-

OEM & ODM support

-

Custom design and tooling services

-

High precision and consistency

-

Competitive pricing with fast delivery

At SW, we focus not only on production but also on providing technical consultation to help customers select the most appropriate sealing material and profile for their specific application.

each sealing strip material offers unique benefits

From PVC and EPDM to silicone and TPE, each sealing strip material offers unique benefits. Choosing the right type depends on the application environment, required flexibility, and budget.

For most general-purpose sealing needs — from doors and windows to industrial machinery — PVC sealing strips remain the most cost-effective and versatile choice.

As a trusted sealing strip manufacturer with 20 years of expertise, SW provides premium-quality PVC sealing strips and other extruded sealing solutions tailored to your project.

If you’re looking for a reliable sealing strips supplier, contact SW today for customized, high-performance sealing solutions built to last.

We have a PVC pipes factory of skilled engineers ready to support you in your product development journey from idea design to production.Any ideas about your product you can contact us freely,and our engineers will get back to you with a quote asap. Whatsapp +86 188 2072 7151

Who is Shuowei?

Since 2006, Shuowei is a professional extrusion profiles factory based in Guangdong, China. There are total about 51-100 people in our office. Shuowei PVC extrusion factory is committed to the design and production of extruded profiles, such as PVC pipes, PE trunking, PVC skirting line. Since its inception, we have won the wide recognition of the market and the deep trust of customers with our ingenious design, exquisite technology and the ultimate pursuit of quality.

Are you a manufacturer or a trader?

We are a Chinese top PVC extrusion profiles manufacturer and our factory is located in Huizhou. Our factory has a 16,000㎡ production base, 5+ automated extrusion profiles production lines, an annual production capacity of 30,000 tons, and serves more than 500 customers worldwide. Welcome to visit our factory!

What is your product range?

We pecialize in the design and production of high quality extrusion profiles,such as PVC pipe, ABS extrusion, PC lampshades, PVC skirting lines, PP trunking, PE profiles…

How long does the custom development process take?

We support custom extrusion products. The usual process has 4 steps: demand confirmation → 3D design/proofing → test certification → mass production (cycle 3-8 weeks).

Do you have any international certifications?

We have passed ISO 9001, CE, RoHS, SGS and other certifications, and meet the mainstream standards of Europe, America, the Middle East and Asia