In modern construction, automotive, and industrial applications, PVC sealing strips are essential for protecting against water, dust, vibration, and temperature fluctuations. Whether used in doors, windows, refrigeration units, or machinery housings, a properly selected and installed PVC sealing strip ensures energy efficiency, comfort, and product longevity.

At SW, a professional PVC sealing strip manufacturer with 20 years of extrusion experience, we often meet customers who ask:

“How do I choose the right sealing strip?”

“What’s the correct installation method?”

“How can I avoid sealing failure?”

This comprehensive guide answers all those questions — covering how to choose, install, and maintain PVC sealing strips effectively.

1. What Is a PVC Sealing Strip?

A PVC sealing strip is a flexible extruded profile made of polyvinyl chloride (PVC), designed to fill gaps and prevent leakage between two surfaces. It acts as a physical barrier against dust, air, moisture, sound, and vibration.

Common Applications:

Door and window sealing

Automotive weatherstripping

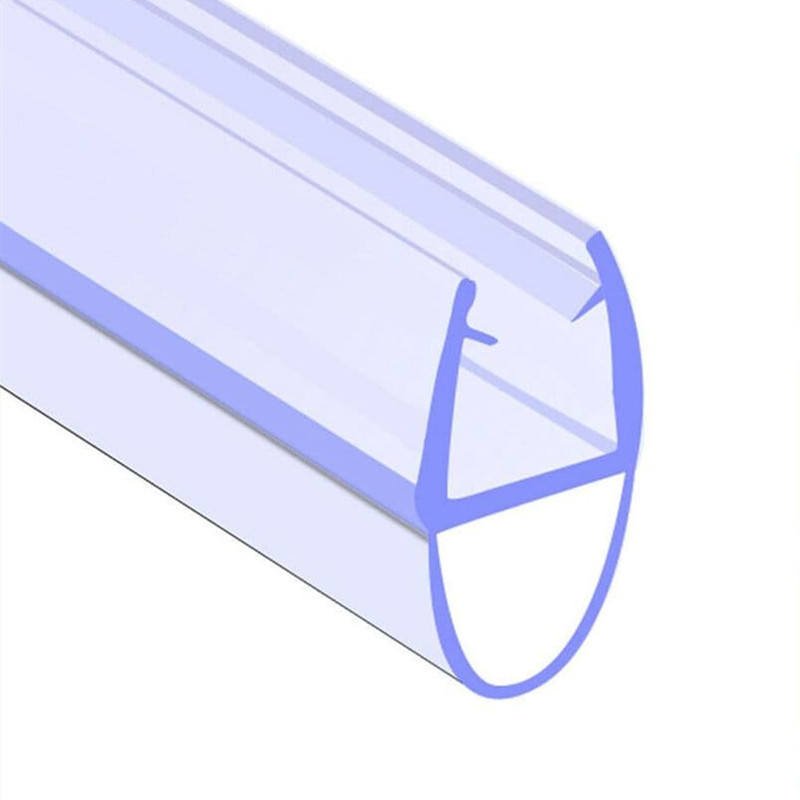

Shower enclosures and bathroom fittings

Electrical cabinet protection

Refrigerator and freezer doors

Industrial equipment covers

PVC is one of the most versatile materials for sealing applications because it offers:

Excellent flexibility and durability

Resistance to water, oil, and chemicals

Easy co-extrusion with other materials

Affordable cost-performance ratio

2. Why Choose PVC Over Other Materials?

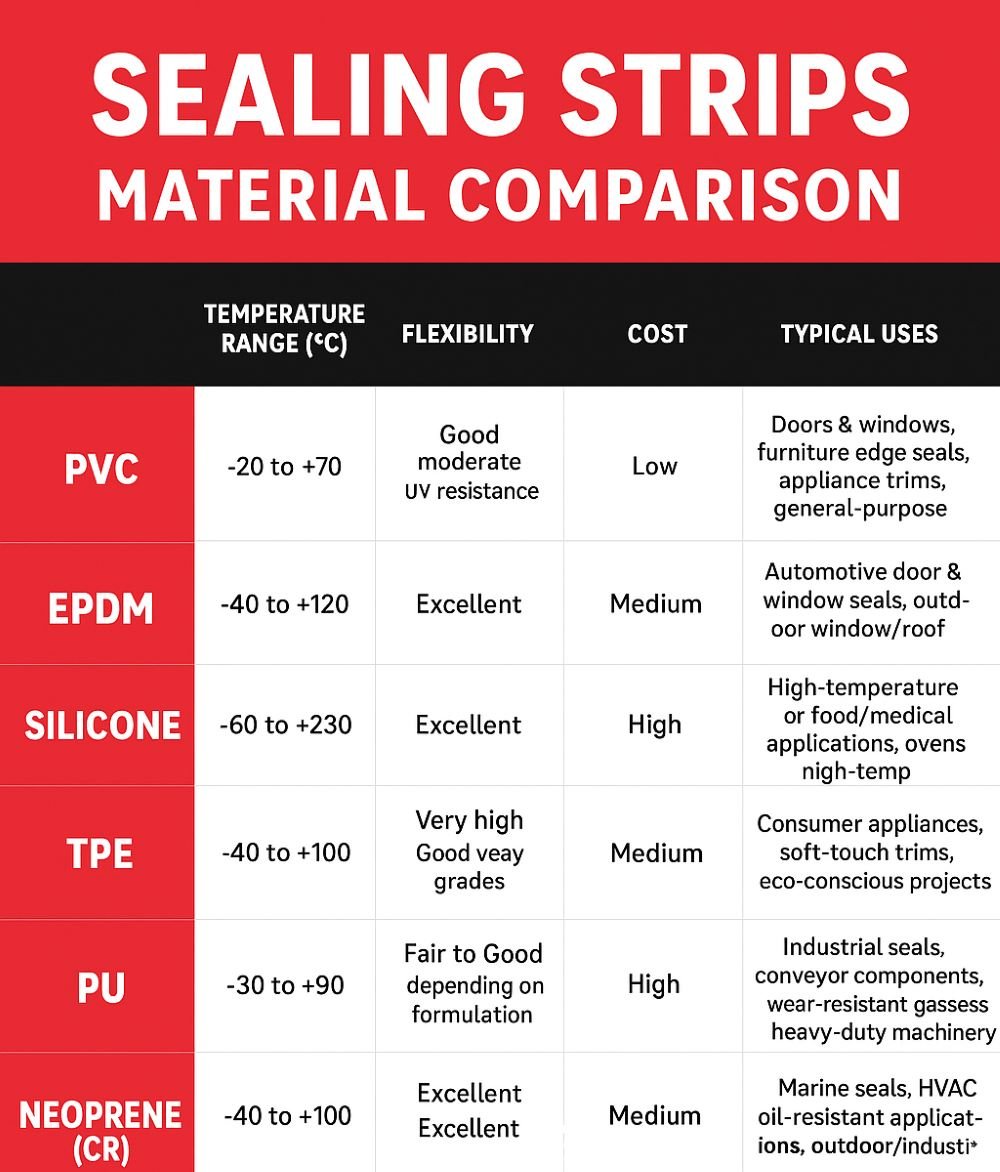

Compared with silicone, rubber, or TPE, PVC sealing strip provide a balance between performance and cost.

| Material | Advantages | Limitations | Typical Uses |

|---|---|---|---|

| PVC | Cost-effective, flexible, customizable, UV resistant | Limited at extreme temperatures | Doors, windows, construction |

| EPDM Rubber | Excellent weather & ozone resistance | Higher cost | Automotive seals, outdoor applications |

| Silicone | Extreme temperature range, food safe | Expensive | Oven doors, cleanrooms |

| TPE | Eco-friendly, recyclable | Slightly softer | Modern consumer products |

For most indoor and moderate outdoor applications, PVC sealing strips are the most practical and economical choice.

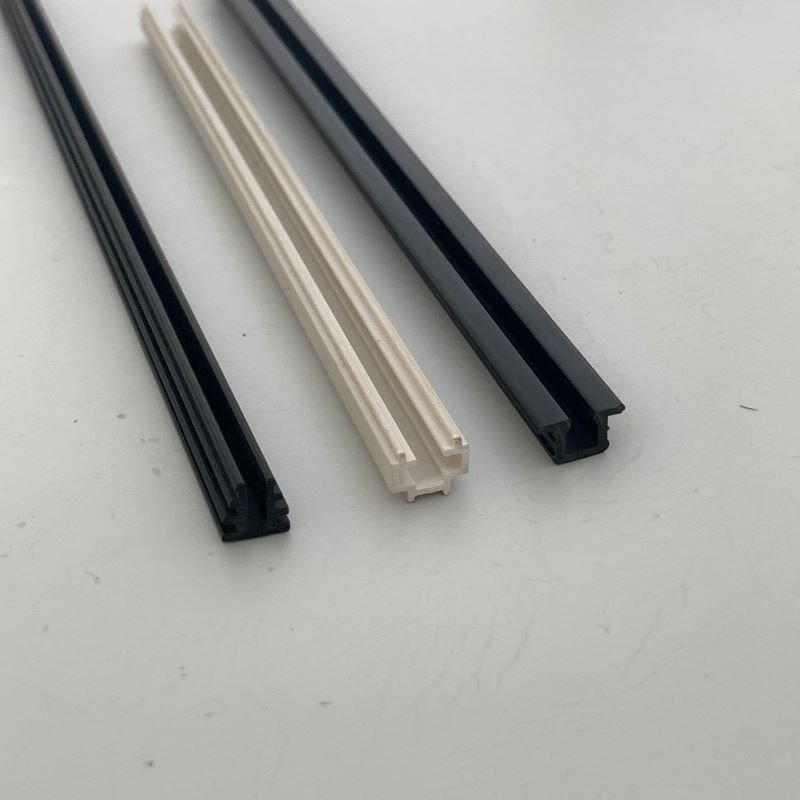

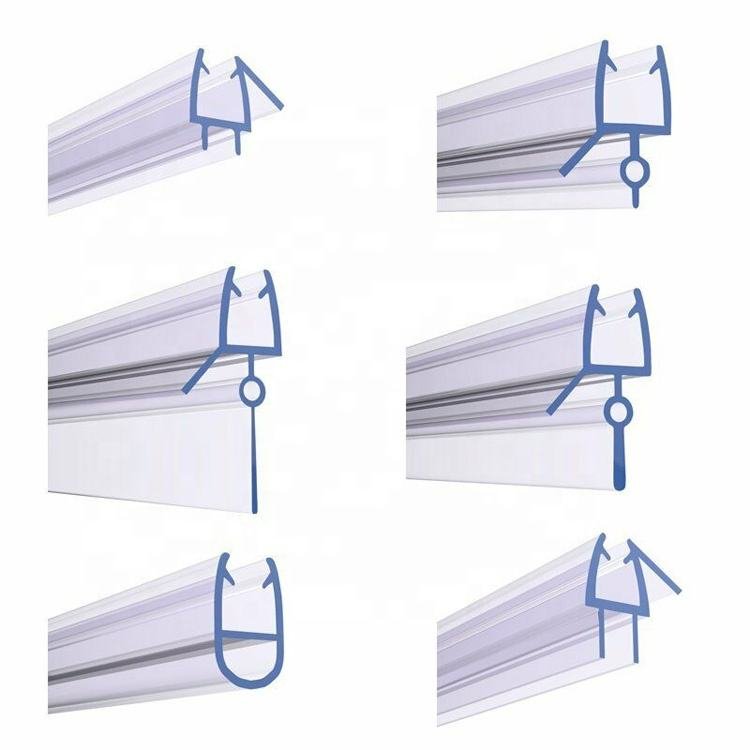

3. Types of PVC Sealing Strip

Soft PVC Strips: Used for tight seals and vibration reduction.

Rigid PVC Strips: Provide structure or support (often as base layer).

Co-extruded PVC Strips: Combine rigid and soft PVC for strength + flexibility.

Adhesive-Backed PVC Strips: Easy peel-and-stick installation.

Magnetic PVC Sealing Strips: Ideal for refrigerators or enclosures.

4. How to Choose the Right PVC Sealing Strip

Step 1: Define the Application

Start by identifying the environment:

Indoor or outdoor?

Temperature range?

Contact with chemicals or UV light?

Step 2: Measure the Gap or Joint

Accurate gap measurement ensures the correct compression and sealing effect. Too tight = deformation; too loose = leaks.

Step 3: Select the Correct Hardness

Hardness (measured in Shore A) determines flexibility.

Soft (60–70 Shore A): best for doors and windows.

Medium (75–85): for industrial equipment.

Hard (90+): for structural trims.

Step 4: Consider Adhesion

If you need quick installation, choose adhesive-backed PVC sealing strips. For long-term structural use, mechanical fastening is preferred.

Step 5: Verify Compliance

Check for RoHS, REACH, and ISO certifications to ensure material safety and performance stability.

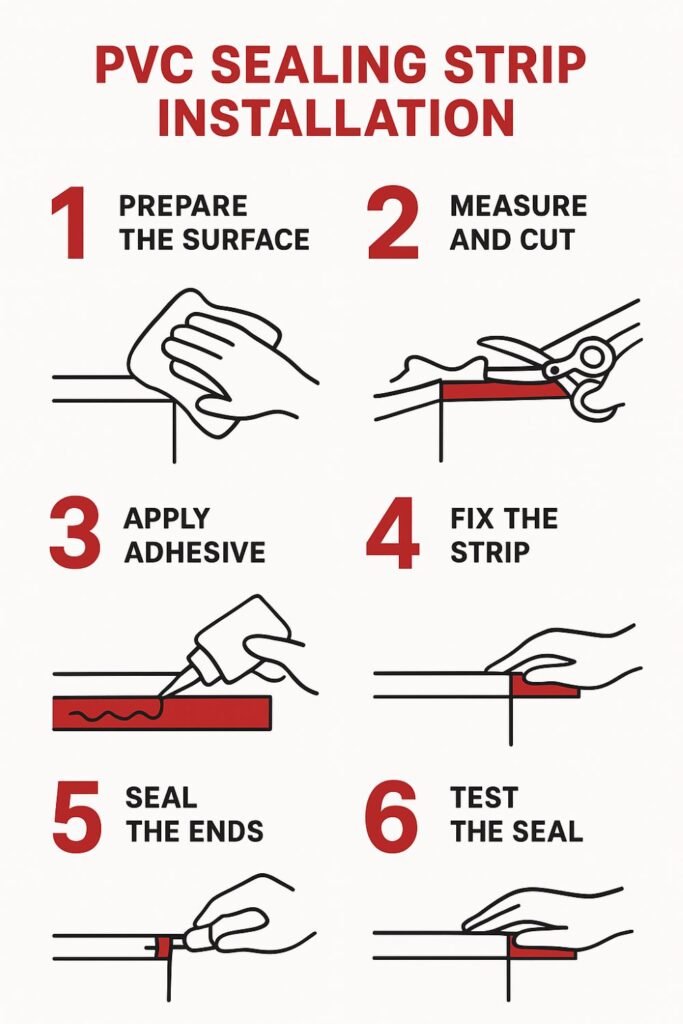

5. Step-by-Step: How to Install a PVC Sealing Strip

Installing a PVC sealing strip properly is key to achieving an effective seal. Below is a professional method used by SW technicians.

Step 1 — Prepare the Surface

Clean the surface thoroughly.

Remove dust, oil, and old adhesive.

Make sure it’s completely dry before applying the new strip.

Step 2 — Measure and Cut

Use a measuring tape to determine the required length.

Cut the PVC sealing strip with scissors or a utility knife.

For corners, use a 45° angle cut for a seamless joint.

Step 3 — Apply Adhesive (if applicable)

If your strip doesn’t come with adhesive backing:

Use a compatible PVC glue or contact adhesive.

Apply a thin, even layer to both surfaces.

Wait 1–2 minutes before joining.

Step 4 — Fix the Strip

Align the strip carefully and press it along the marked line.

Ensure even pressure to avoid air bubbles or gaps.

For long installations, use rollers for better adhesion.

Step 5 — Seal the Ends

Use a sealing compound or corner cap to close open ends. This prevents water or air ingress.

Step 6 — Test the Seal

Check for uniform compression.

Apply light pressure or water spray to ensure no leakage.

6. Installation Tips for Long-Term Performance

Store strips properly — avoid direct sunlight or high heat before installation.

✅ Install at room temperature (15–30°C) for best flexibility.

✅ Avoid stretching the strip during installation; it will shrink back.

✅ Press firmly along the full length to activate adhesive bonding.

✅ Use primers for non-porous or uneven surfaces.

7. Common Mistakes to Avoid

❌ Applying on dusty or oily surfaces

❌ Using incompatible adhesives

❌ Overstretching the strip

❌ Leaving gaps at corners or joints

❌ Installing in extreme cold or heat

Each of these can cause adhesion failure or leakage, reducing the lifespan of the PVC sealing strip.

8. Maintenance and Care

To extend the life of your PVC sealing strip:

Clean regularly using mild soap and water.

Avoid solvents or harsh chemicals.

Inspect annually for cracks or hardening.

Replace if brittle or deformed.

Lubricate sliding seals with silicone oil to reduce friction.

Proper maintenance ensures your sealing strip performs effectively for years.

9. Case Studies: PVC Sealing Strip in Real Applications

Case 1: Building Door Frame Sealing

A construction firm in Dubai replaced traditional EPDM seals with PVC sealing strip produced by SW.

Result: Reduced cost by 25%, faster installation, and improved air tightness.

Case 2: Automotive Edge Sealing

An automotive parts supplier needed durable yet flexible seals for van doors.

SW provided co-extruded PVC sealing strips with UV stabilizers.

Result: Enhanced performance under sunlight exposure, 2× longer lifespan.

Case 3: Refrigeration Door Gaskets

A European appliance manufacturer switched to magnetic PVC sealing strips with custom hardness.

Result: 20% energy savings due to improved sealing performance.

10. How to Choose the Right PVC Sealing Strip Factory

When sourcing your PVC sealing strip, partner with a reliable factory that offers:

| Criteria | What to Look For |

|---|---|

| Experience | 10+ years in extrusion manufacturing |

| Equipment | Twin-screw extruders, vacuum calibration |

| Customization | Hardness, color, shape, co-extrusion |

| Certification | ISO 9001, RoHS, REACH |

| Delivery | Consistent lead times and packaging |

| Support | Engineering design and sample testing |

11. Why Choose SW as Your PVC Sealing Strip Partner

With 20 years of PVC sealing strip manufacturing experience, SW provides complete solutions for global customers — from design to delivery.

Our Key Strengths

Advanced extrusion technology

In-house mold and die design

OEM/ODM customization for brand clients

ISO-certified quality control

Low MOQs and fast sampling

Global export to 50+ countries

SW’s engineers ensure each PVC sealing strip meets your exact sealing, temperature, and color specifications.

12. Troubleshooting: If Your Sealing Strip Fails

| Problem | Cause | Solution |

|---|---|---|

| Peeling or detaching | Dirty surface / poor adhesive | Reclean and reapply with primer |

| Leakage | Improper compression | Choose correct hardness or profile size |

| Cracks | UV or chemical exposure | Use UV-stabilized PVC grades |

| Noise or vibration | Wrong profile shape | Consult factory for redesign |

13. The Future of PVC Sealing Strip

The sealing industry is evolving with technology and sustainability. New trends include:

Recyclable PVC compounds

Bio-based plasticizers (phthalate-free)

Smart sealing systems with embedded magnets or sensors

Eco-efficient co-extrusion with multi-layer designs

SW continues to innovate with green extrusion and energy-efficient production, ensuring environmental responsibility and top performance.

14. Summary: Key Takeaways

PVC sealing strips are versatile, durable, and cost-effective.

✅ Choose based on environment, hardness, and gap size.

✅ Install carefully with proper cleaning and pressure.

✅ Avoid stretching, uneven application, and extreme temperatures.

✅ Partner with a professional PVC sealing strip factory like SW for reliable quality and customization.

The right PVC sealing strip not only improves comfort and efficiency but also enhances your product’s reliability and energy performance. Whether you’re a construction firm, appliance manufacturer, or industrial OEM, investing in professional-quality sealing solutions ensures long-term benefits.

For more information or free technical consultation, contact us at:

📧 lucy@dgsw888.com

🌐https://swpvcextrusion.com

📞 +86-188 2072 7151

Written by SW Technical Team

20+ Years of Professional PVC Sealing Strip Manufacturing

We have a PVC pipes factory of skilled engineers ready to support you in your product development journey from idea design to production.Any ideas about your product you can contact us freely,and our engineers will get back to you with a quote asap. Whatsapp +86 188 2072 7151

Who is Shuowei?

Since 2006, Shuowei is a professional extrusion profiles factory based in Guangdong, China. There are total about 51-100 people in our office. Shuowei PVC extrusion factory is committed to the design and production of extruded profiles, such as PVC pipes, PE trunking, PVC skirting line. Since its inception, we have won the wide recognition of the market and the deep trust of customers with our ingenious design, exquisite technology and the ultimate pursuit of quality.

Are you a manufacturer or a trader?

We are a Chinese top PVC extrusion profiles manufacturer and our factory is located in Huizhou. Our factory has a 16,000㎡ production base, 5+ automated extrusion profiles production lines, an annual production capacity of 30,000 tons, and serves more than 500 customers worldwide. Welcome to visit our factory!

What is your product range?

We pecialize in the design and production of high quality extrusion profiles,such as PVC pipe, ABS extrusion, PC lampshades, PVC skirting lines, PP trunking, PE profiles…

How long does the custom development process take?

We support custom extrusion products. The usual process has 4 steps: demand confirmation → 3D design/proofing → test certification → mass production (cycle 3-8 weeks).

Do you have any international certifications?

We have passed ISO 9001, CE, RoHS, SGS and other certifications, and meet the mainstream standards of Europe, America, the Middle East and Asia