In today’s construction, automotive, and industrial markets, sealing strips play an essential role in ensuring airtightness, waterproofing, sound insulation, and dust protection. Whether used on doors, windows, vehicles, machinery, or bathrooms, sealing strips help prevent leaks, block noise, and enhance energy efficiency.

As a professional PVC sealing strips manufacturer with 20 years of extrusion experience, SW Factory provides high-quality customized sealing solutions for different industries worldwide.

In this article, we’ll explore:

What sealing strips are and their key functions

The most common sealing strip materials (PVC, EPDM, Silicone, TPE, PU, and Neoprene)

Their performance comparisons

Application examples in different industries

How to select the right sealing strip for your project

1. What Are Sealing Strips?

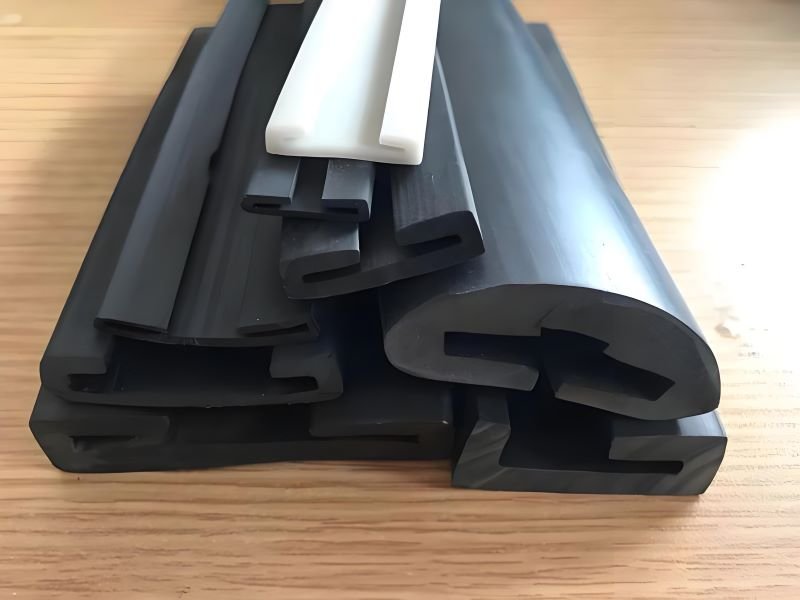

A sealing strip is a flexible profile — usually made of rubber or plastic — designed to fill gaps between surfaces, preventing air, water, dust, or vibration from passing through.

They are commonly extruded into shapes such as D-type, P-type, E-type, and U-type and used in:

Doors and windows (home, industrial, automotive)

Glass and aluminum frames

Machinery and HVAC systems

Refrigerators and cabinets

Bathrooms, kitchens, and waterproofing areas

Key Functions of Sealing Strips

Sealing: Preventing leaks of air, water, and sound.

Cushioning: Reducing vibration and noise.

Protection: Avoiding dust, corrosion, and impact.

Energy Efficiency: Enhancing insulation and reducing heat loss.

2. Common Sealing Strip Materials Overview

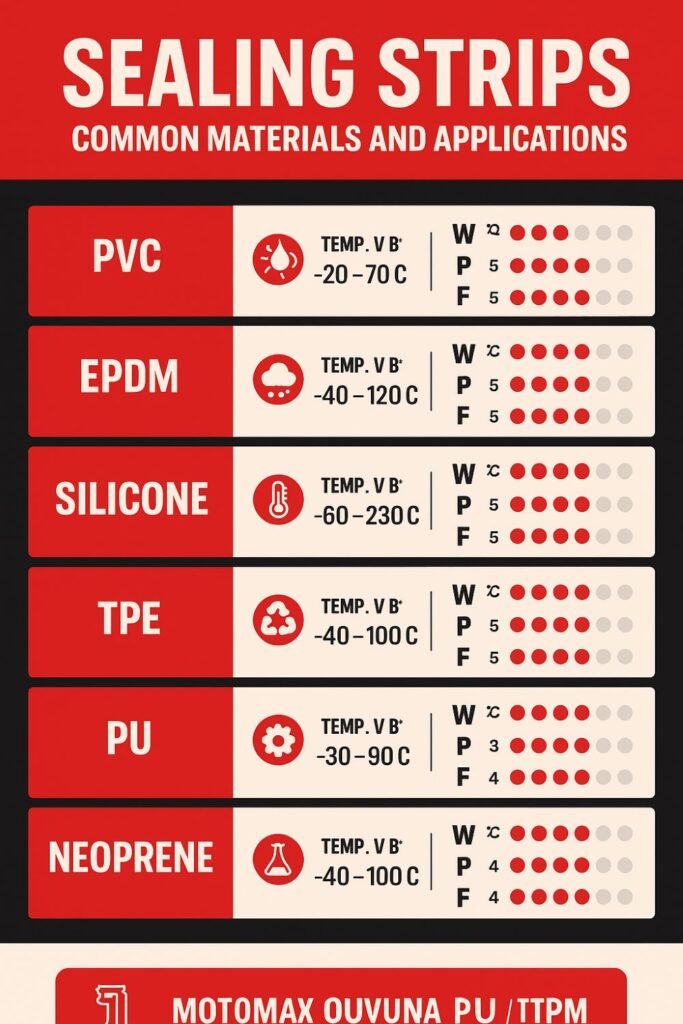

Let’s examine the six most widely used sealing strips materials and their technical properties.

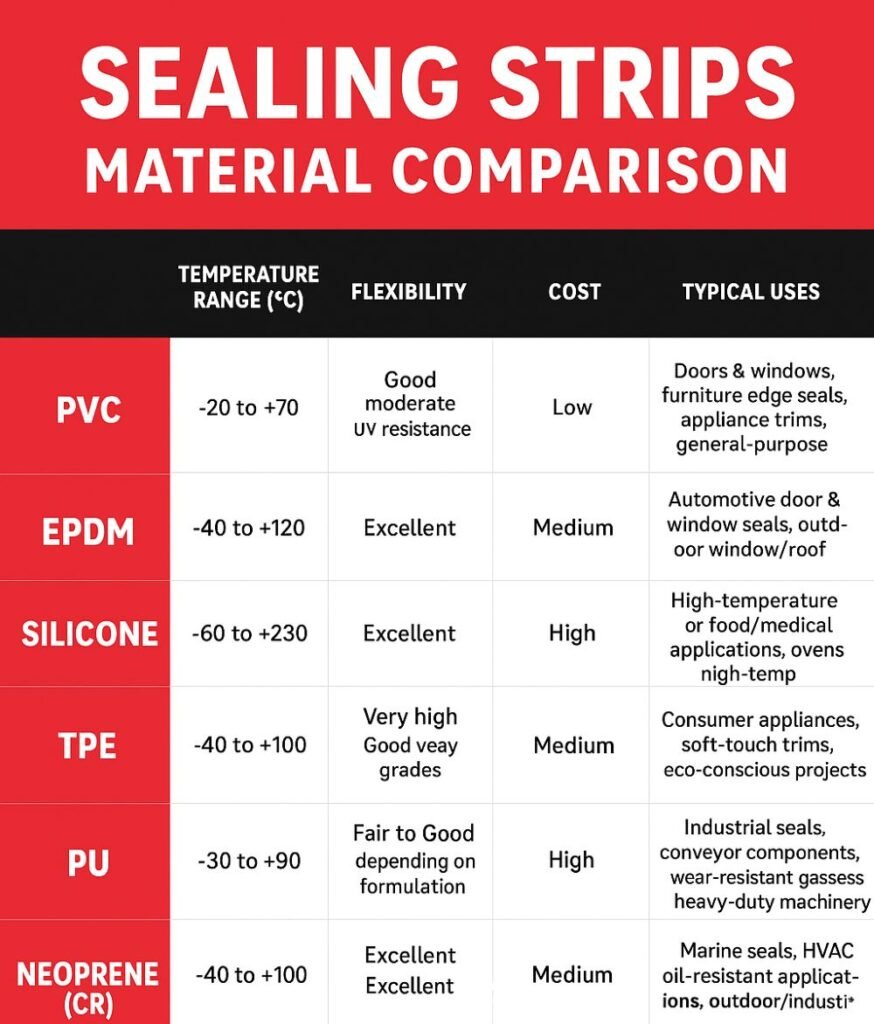

| Material | Temperature Range | Flexibility | Weather Resistance | Cost | Key Applications |

|---|---|---|---|---|---|

| PVC | -20°C to 70°C | High | Moderate | ★★★ | General building, furniture, indoor sealing |

| EPDM | -40°C to 120°C | Excellent | Excellent | ★★★★ | Automotive, construction, industrial |

| Silicone | -60°C to 230°C | Excellent | Excellent | ★★★★★ | Medical, food, high-temperature |

| TPE | -40°C to 100°C | Very High | Good | ★★★ | Consumer products, household appliances |

| PU (Polyurethane) | -30°C to 90°C | Good | Fair | ★★ | Industrial, machinery seals |

| Neoprene | -40°C to 100°C | Good | Excellent | ★★★ | Marine, outdoor, weatherproof sealing |

3. PVC Sealing Strips

PVC is one of the most versatile materials for sealing strips, widely used in doors, windows, furniture, and interior decoration.

Advantages

Cost-effective and easy to extrude

Excellent water resistance and chemical stability

Available in various hardness (from soft to rigid)

Suitable for large-volume manufacturing and customization

Applications

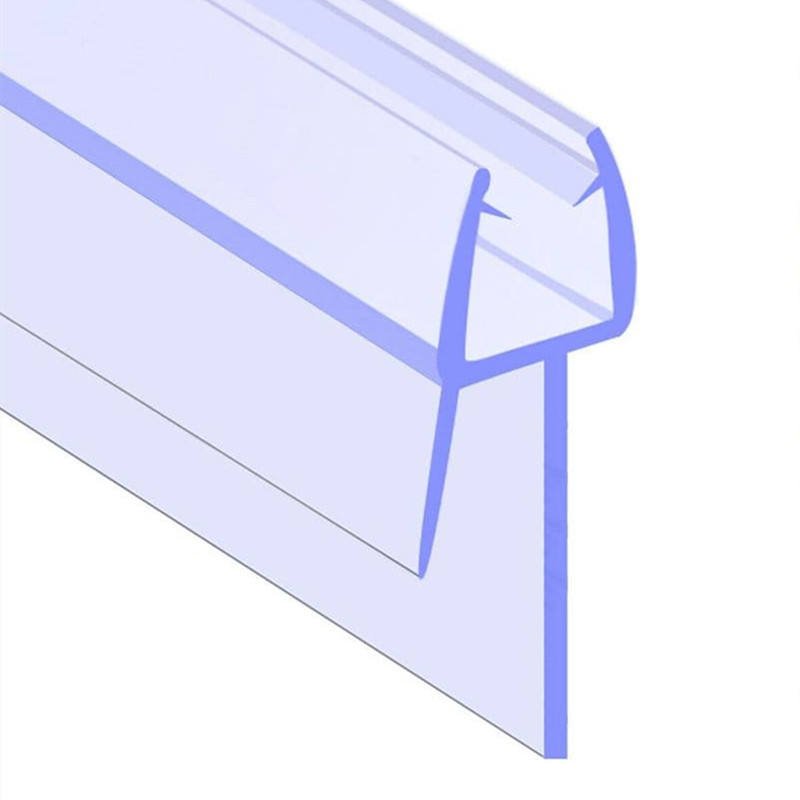

Doors and Windows: Tight sealing, dust protection, and insulation

Furniture & Cabinets: Decorative and sealing functions combined

Bathrooms: Water and mold resistance

Limitations

Not suitable for extreme cold or heat

Slightly less flexible than rubber materials

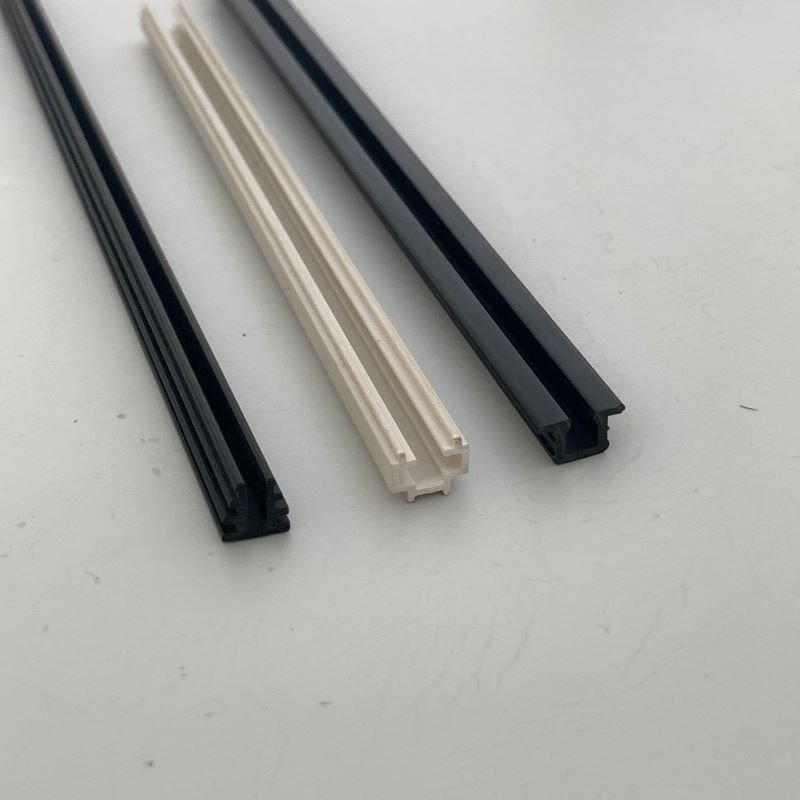

SW Factory specializes in custom PVC sealing strips, offering precise extrusion, co-extrusion (dual hardness), and color matching for OEM clients.

4. EPDM Sealing Strips

EPDM (Ethylene Propylene Diene Monomer) is a synthetic rubber known for its excellent weather, UV, and ozone resistance.

Advantages

Outstanding durability under sunlight and temperature changes

Excellent flexibility and elasticity

Great for outdoor and automotive applications

Applications

Automotive Door Seals: Reduces vibration and noise

Building Windows & Roofs: Weatherproof sealing

Industrial Machines: Long-term outdoor protection

Limitations

Slightly higher cost than PVC

Not ideal for food or medical-grade applications

Best choice for: Outdoor environments, construction, and automotive industries.

5. Silicone Sealing Strips

Silicone rubber stands out for extreme temperature resistance and non-toxicity, making it ideal for medical, food, and cleanroom environments.

Advantages

Temperature tolerance: -60°C to +230°C

Excellent flexibility and rebound

Non-toxic and odorless

High resistance to UV, ozone, and chemicals

Applications

Ovens and Food Equipment: High-temperature sealing

Medical Devices: Non-toxic sealing

Electronics: Heat-resistant gaskets

Limitations

Higher cost

Lower mechanical strength compared to EPDM

Best choice for: High-performance environments where cleanliness and heat resistance matter.

6. TPE Sealing Strips

TPE (Thermoplastic Elastomer) combines the properties of rubber and plastic — offering elasticity, reusability, and easy processing.

Advantages

100% recyclable

Soft touch and high elasticity

Easy to co-extrude with other plastics (like PVC)

Excellent for consumer products and interiors

Applications

Household appliances (refrigerators, washing machines)

Office equipment

Furniture and decorations

Limitations

Moderate resistance to weather and heat

Can deform under prolonged compression

Best choice for: Indoor and semi-protected environments needing flexibility and aesthetic appeal.

7. PU (Polyurethane) Sealing Strips

PU offers excellent abrasion resistance and mechanical strength, making it ideal for industrial sealing.

Advantages

High tensile and tear strength

Excellent resistance to oil and chemicals

Can be molded or extruded easily

Applications

Machinery & Equipment: Shock absorption and sealing

Automotive: Vibration-dampening components

Industrial Doors: Heavy-duty protection

Limitations

Sensitive to moisture and UV light

Shorter lifespan outdoors

Best choice for: Industrial and machinery seals requiring strength and durability.

8. Neoprene Sealing Strips

Neoprene (Chloroprene Rubber) is well known for its resistance to oil, ozone, and weathering, widely used in marine and industrial environments.

Advantages

Good balance of flexibility, durability, and chemical resistance

Works well in outdoor, industrial, and marine settings

Flame retardant options available

Applications

Marine Equipment

Outdoor Construction

HVAC Systems

Limitations

Moderate flexibility

Slightly heavier and costlier than PVC

Best choice for: Environments exposed to oils, chemicals, or marine conditions.

9. Comparative Analysis: PVC vs. Rubber Sealing Strips

| Material | Temperature range (°C) | Flexibility | Weather / UV resistance | Cost | Typical uses |

|---|---|---|---|---|---|

| PVC | -20 to +70 | High — good bendability for profiles | Good (moderate UV resistance; UV-stabilized grades recommended for long outdoor life) | Low | Doors & windows, furniture edge seals, appliance trims, general-purpose building seals |

| EPDM | -40 to +120 | Excellent — great rebound and compression recovery | Excellent (outstanding UV/ozone/weather resistance) | Medium | Automotive door & window seals, outdoor window/roof seals, long-life weather seals |

| Silicone | -60 to +230 | Excellent — remains flexible at extreme temps | Excellent (very high UV/ozone/weather resistance) | High | High-temperature or food/medical applications, ovens, high-temp gaskets, electronics |

| TPE (Thermoplastic Elastomer) | -40 to +100 | Very high — rubber-like feel, easy co-extrusion | Good (many grades with good weather resistance) | Medium | Consumer appliances, soft-touch trims, eco-conscious projects, co-extruded seals |

| PU (Polyurethane) | -30 to +90 | Good — strong and elastic under load | Fair to Good (depends on formulation; abrasion-resistant grades available) | High | Industrial seals, conveyor components, wear-resistant gaskets, heavy-duty machinery |

| Neoprene (CR) | -40 to +100 | Good — durable and resilient | Excellent (good weather, ozone and oil resistance) | Medium | Marine seals, HVAC, oil-resistant applications, outdoor/industrial environments |

From this table, PVC sealing strips remain the most cost-effective choice for indoor sealing needs, while EPDM and Silicone excel in outdoor and high-temperature applications.

10. Real-World Application Examples

Case 1: Residential Doors and Windows

Material Used: PVC sealing strips

Reason: Affordable, easy installation, aesthetic match

Result: Improved insulation and reduced noise leakage

Case 2: Automotive Door Gasket

Material Used: EPDM sealing strips

Reason: Superior weather and vibration resistance

Result: Enhanced durability and sound insulation

Case 3: Food Equipment Gasket

Material Used: Silicone sealing strips

Reason: Non-toxic, heat-resistant

Result: Safe and hygienic sealing performance

Case 4: Marine Hatch Seals

Material Used: Neoprene sealing strips

Reason: Saltwater and oil resistance

Result: Long-lasting outdoor performance

11. How to Choose the Right Sealing Strip Material

Here are the key selection factors when choosing sealing strips:

Operating Environment:

Indoor (PVC, TPE) vs. Outdoor (EPDM, Neoprene) vs. High-temp (Silicone).Temperature Range:

Choose material that stays flexible within your working range.Exposure Conditions:

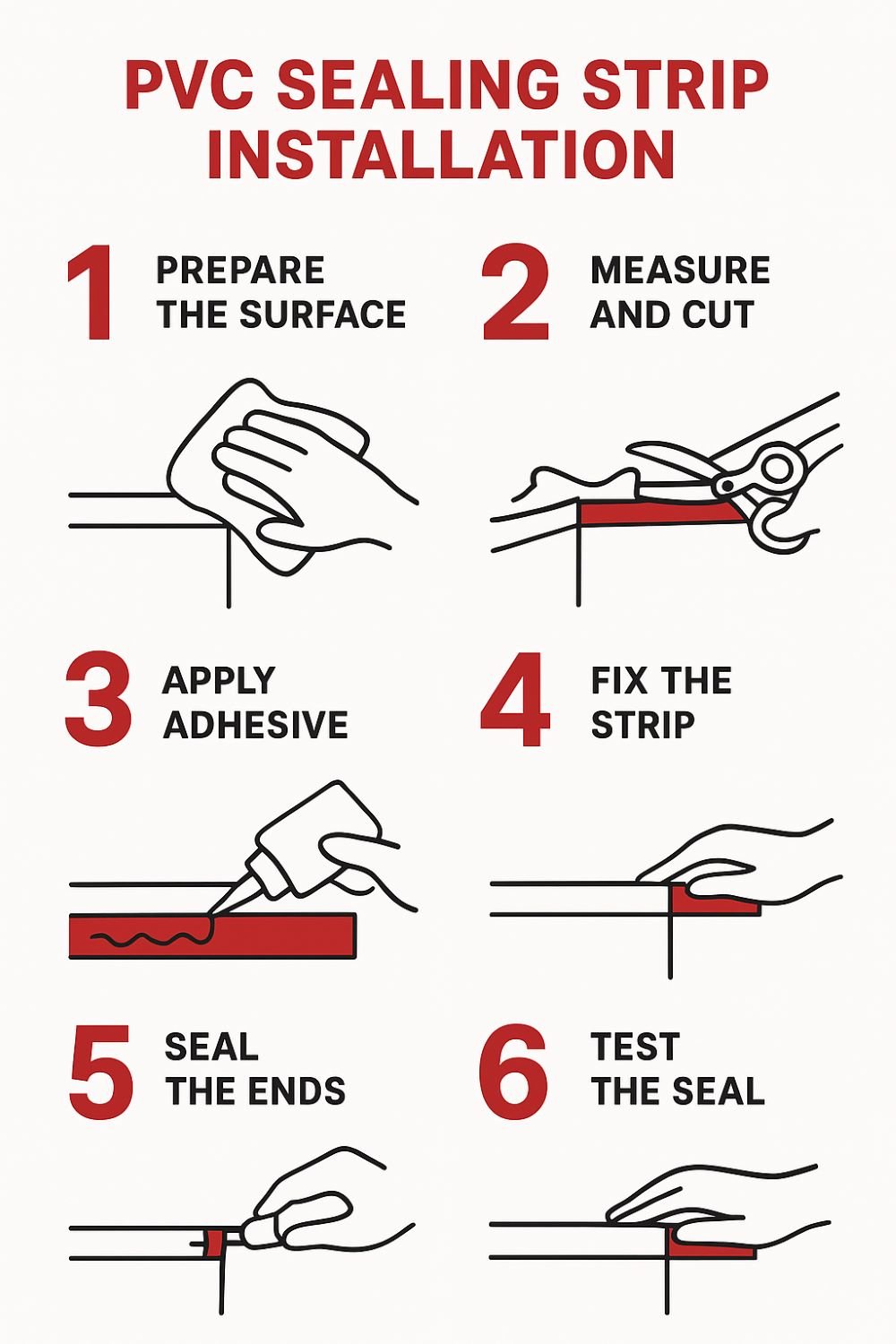

Consider UV, ozone, oil, or chemical exposure.Hardness and Flexibility:

Match material hardness (Shore A scale) to application pressure and gap width.Installation and Maintenance:

PVC and TPE are easier to install and replace than some rubber materials.Cost and Lifespan:

PVC = economical; Silicone = premium performance.

12. Why Choose SW as Your PVC Sealing Strips Supplier

With 20 years of extrusion manufacturing experience, SW Factory provides:

Advanced co-extrusion and color-matching capabilities

Custom shapes and hardness levels (40A–90A)

OEM/ODM services for brands and project contractors

Strict quality control (ISO 9001 certified)

Fast global delivery and responsive support

We help customers in construction, furniture, automotive, and industrial sectors select or design the best PVC sealing strips for their needs.

PVC sealing strips remain the best choice

When selecting sealing strips, understanding the material differences is essential for achieving the right balance between performance, cost, and durability.

For indoor and decorative uses, PVC sealing strips remain the best choice for value and versatility. For outdoor, automotive, or industrial uses, EPDM, Silicone, or Neoprene may be more suitable.

No matter your project, choosing a reliable manufacturer like SW Factory ensures consistent quality, customized design, and professional support.

We have a PVC pipes factory of skilled engineers ready to support you in your product development journey from idea design to production.Any ideas about your product you can contact us freely,and our engineers will get back to you with a quote asap. Whatsapp +86 188 2072 7151

Who is Shuowei?

Since 2006, Shuowei is a professional extrusion profiles factory based in Guangdong, China. There are total about 51-100 people in our office. Shuowei PVC extrusion factory is committed to the design and production of extruded profiles, such as PVC pipes, PE trunking, PVC skirting line. Since its inception, we have won the wide recognition of the market and the deep trust of customers with our ingenious design, exquisite technology and the ultimate pursuit of quality.

Are you a manufacturer or a trader?

We are a Chinese top PVC extrusion profiles manufacturer and our factory is located in Huizhou. Our factory has a 16,000㎡ production base, 5+ automated extrusion profiles production lines, an annual production capacity of 30,000 tons, and serves more than 500 customers worldwide. Welcome to visit our factory!

What is your product range?

We pecialize in the design and production of high quality extrusion profiles,such as PVC pipe, ABS extrusion, PC lampshades, PVC skirting lines, PP trunking, PE profiles…

How long does the custom development process take?

We support custom extrusion products. The usual process has 4 steps: demand confirmation → 3D design/proofing → test certification → mass production (cycle 3-8 weeks).

Do you have any international certifications?

We have passed ISO 9001, CE, RoHS, SGS and other certifications, and meet the mainstream standards of Europe, America, the Middle East and Asia