From construction and automotive to household appliances and marine systems, PVC sealing strips play a critical role in sealing, insulation, and protection. Behind every reliable sealing product stands a specialized PVC sealing strip factory equipped with advanced extrusion lines, precise tooling, and strict quality management.

Choosing the right PVC sealing strip factory isn’t only about price — it’s about long-term performance, customizability, technical support, and supply consistency. This guide will help you understand how to select the right manufacturer and introduce the Top 10 PVC sealing strip factories in 2025, including SW, a global leader with 20 years of extrusion experience.

1. Understanding PVC Sealing Strips

1.1 What Are PVC Sealing Strips?

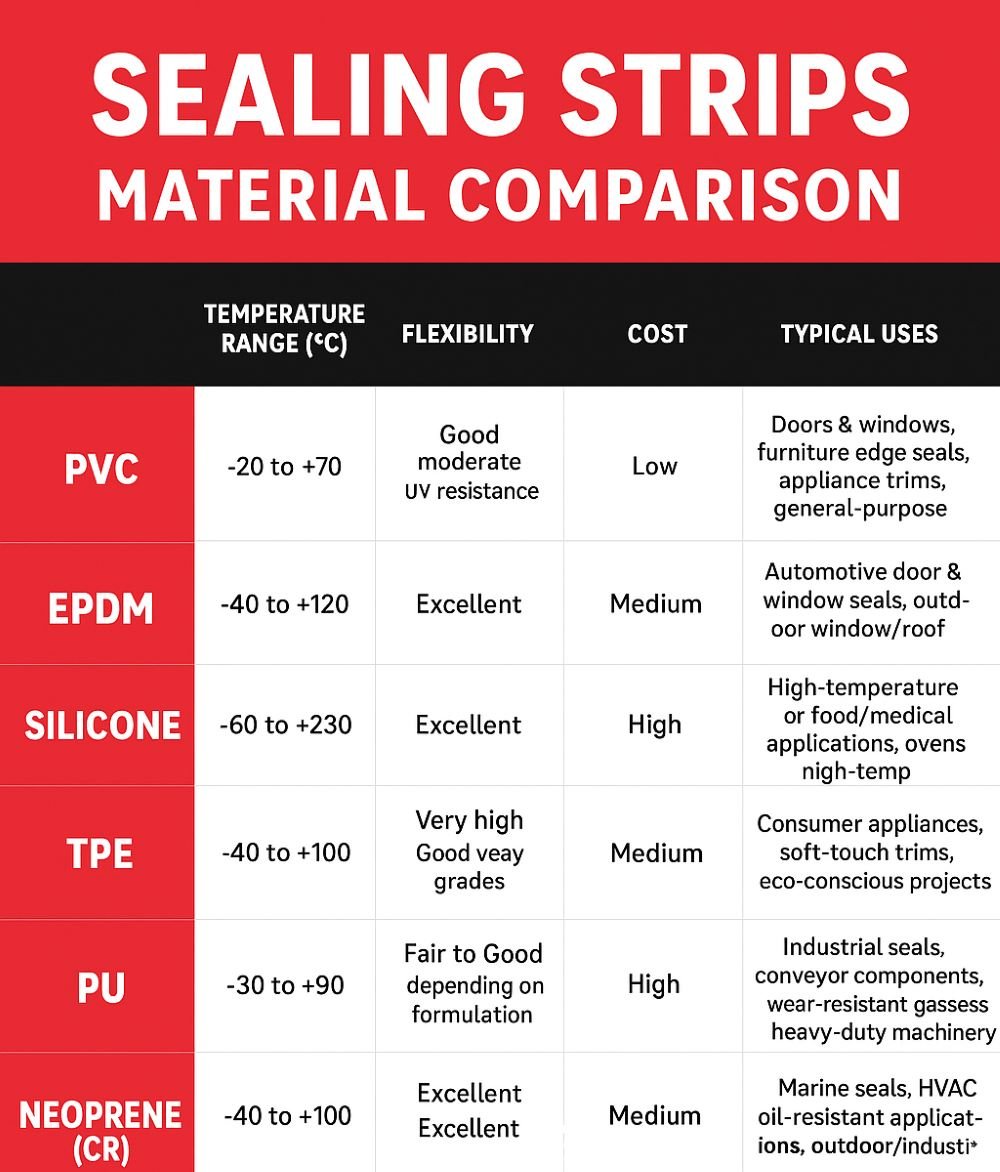

PVC sealing strips are flexible extruded profiles made from polyvinyl chloride (PVC). They are used to fill gaps, absorb vibration, prevent leaks, and protect against dust, water, and air infiltration.

Common uses include:

Door and window frame seals

Automotive edge trims

Refrigerator and appliance gaskets

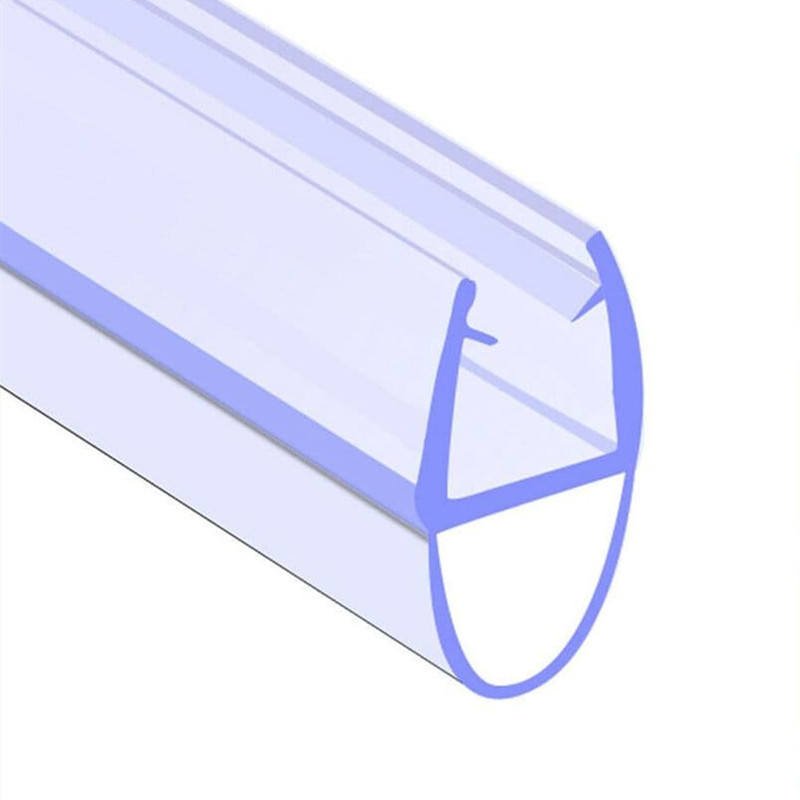

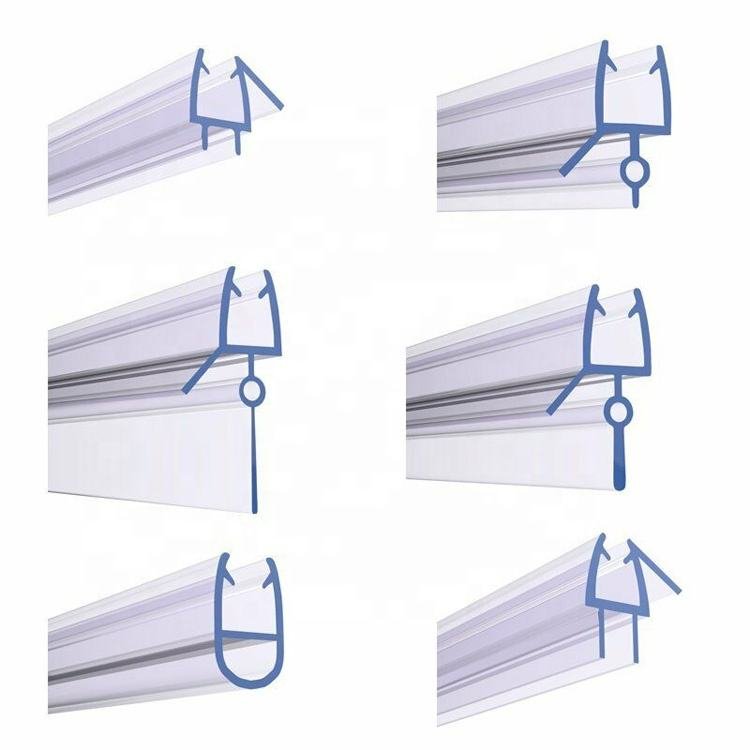

Shower door seals

Industrial equipment sealing

1.2 Why PVC?

PVC is cost-effective, durable, and easy to process through extrusion. Compared to rubber or silicone, it offers an excellent balance of price, flexibility, and chemical resistance. PVC can also be modified — soft, semi-rigid, or co-extruded with rigid backing — to match various installation needs.

2. Key Factors in Choosing a PVC Sealing Strip Factory

When sourcing from a PVC sealing strip factory, consider the following technical and business aspects:

2.1 Material Formulation Expertise

PVC compounds vary widely. The best factories customize plasticizers, stabilizers, and UV additives based on your target market (e.g., REACH or RoHS compliance).

A qualified factory will:

Offer both soft and rigid PVC extrusion.

Use non-toxic, heavy-metal-free formulas.

Provide color matching and flame-retardant options.

2.2 Extrusion Technology

Look for manufacturers using precision twin-screw extruders and automatic calibration systems. This ensures consistent wall thickness, dimensional stability, and smooth surfaces.

Modern factories often have:

Vacuum calibration tanks

Automatic cutting systems

Inline measurement & defect detection

2.3 Mold Design Capability

Every sealing strip shape requires a custom die. A capable PVC sealing strip factory should have in-house mold design and CNC machining capabilities for fast prototyping and cost control.

2.4 Quality Management

Check for ISO 9001 certification, traceable inspection systems, and full documentation (raw material batches, tensile strength, hardness, compression set, etc.).

2.5 Customization and Co-extrusion

A flexible factory can provide:

Dual-hardness PVC profiles

Co-extrusion with magnets or foamed cores

Pre-applied adhesive backing

2.6 Production Capacity & Lead Time

Top factories run multiple extrusion lines for different profile sizes and colors, with daily capacities from 3–10 tons. Ensure the supplier can handle your volume and maintain short lead times.

2.7 After-sales Service and OEM Support

Strong technical service makes long-term cooperation possible. Leading suppliers like SW provide design drawings, tooling samples, installation guides, and export packaging solutions.

3. How PVC Sealing Strips Are Manufactured

Understanding the production process helps you evaluate a factory’s technical strength.

Step 1 — Raw Material Preparation

PVC resin is blended with plasticizers, stabilizers, lubricants, and pigments to achieve the desired hardness (usually 60–90 Shore A).

Step 2 — Extrusion

The compound is melted and extruded through a precision die. The molten profile enters a cooling tank to solidify its final shape.

Step 3 — Calibration & Sizing

A vacuum calibration unit ensures dimensional stability and smooth surfaces.

Step 4 — Cutting & Finishing

Strips are cut to specific lengths or wound on coils. Labels and packaging are added for traceability.

Step 5 — Quality Inspection

Testing includes:

Dimensional accuracy

Shore hardness

Compression recovery

Color consistency

Adhesion (for adhesive-backed types)

4. Applications of PVC Sealing Strips

| Application | Description | Key Features Required |

|---|---|---|

| Doors & Windows | Prevent air leakage, vibration, and noise | Flexibility, UV resistance |

| Automotive Seals | Edge protection, vibration damping | Heat & oil resistance |

| Refrigeration | Airtight gasket to retain cold air | Low-temperature flexibility |

| Construction Panels | Waterproof joints in wall panels | Flame retardancy, color match |

| Electronics & Appliances | Cable and enclosure sealing | Electrical insulation |

5. Top 10 PVC Sealing Strip Factories in 2025

1. SW – China

Website: www.swextrusion.com

With over 20 years of PVC extrusion experience, SW is one of China’s leading PVC sealing strip factories. The company offers full OEM/ODM customization, from material formulation to mold development.

Key strengths:

20 + years of extrusion experience

In-house tooling and CAD design

ISO-certified quality control

Fast sample delivery (within 10 days)

Global export (Europe, Middle East, Americas)

Applications: doors, windows, appliances, building profiles.

Factory location: Zhejiang, China.

2. GasketSeal Co. (Germany)

Specializes in precision co-extruded PVC and EPDM sealing profiles. Known for tight dimensional tolerances and European automotive compliance.

3. PolySeal Industries (USA)

Manufacturer of high-performance extruded seals for HVAC, construction, and OEM equipment. Offers REACH-compliant PVC compounds.

4. Ningbo Extrutec (China)

A modern PVC sealing strip factory with advanced twin-screw extrusion and 24-hour automated lines.

5. Trim-Lok Inc. (USA)

Known globally for edge trims and sealing solutions. Offers both PVC and rubber-based sealing profiles for vehicles and marine industries.

6. Kunsha BestSeal (China)

Strong in custom co-extrusion and multi-material sealing strips for windows and industrial enclosures.

7. Sealflex Plastics (India)

Large exporter of flexible PVC sealing strips and thermoplastic elastomer (TPE) alternatives. Cost-effective production with stable quality.

8. SealPro Manufacturing (UK)

Specialist in door and window sealing profiles. Offers full OEM design and color customization.

9. Guangzhou Lume Plastic (China)

High-capacity PVC sealing strip factory with more than 15 extrusion lines and strong packaging solutions for export.

10. TechnoRub Sealing Systems (Turkey)

Provides hybrid sealing profiles (PVC + EPDM) for construction and automotive sectors. Known for strong R&D support.

7. How to Evaluate a PVC Sealing Strip Factory

When comparing suppliers, create a technical checklist covering:

| Criteria | Why It Matters | Target Value |

|---|---|---|

| Material hardness | Determines flexibility & sealing pressure | 60–90 Shore A |

| Tolerance control | Affects fit and appearance | ±0.1 mm or better |

| UV resistance | For outdoor or sunlight exposure | ≥ 5 years outdoor life |

| Tensile strength | Indicates durability | > 8 MPa |

| Dimensional stability | Prevents shrinkage | < 2 % |

| Certification | Confirms compliance | ISO 9001, RoHS, REACH |

8. Why Choose SW as Your PVC Sealing Strip Factory

SW offers a one-stop solution for global OEM customers:

Custom Formulation: Tailored hardness, color, UV, and flame-retardant levels.

Advanced Equipment: 15 + extrusion lines with strict dimensional calibration.

Mold Workshop: Rapid die development with CNC precision.

OEM/ODM Support: From idea to finished product — drawings, samples, and bulk delivery.

Quality Assurance: 100% inspection before shipment.

Global Export Experience: Serving clients in over 50 countries.

SW’s approach is “engineer-driven customization.” The team helps customers reduce cost and improve product performance through professional extrusion design.

9. FAQs About PVC Sealing Strip Factories

Q1: What’s the minimum order quantity (MOQ)?

Most factories require 500–1000 meters per profile; SW offers lower MOQs for development.

Q2: How long does mold development take?

Typically 7–15 days depending on profile complexity.

Q3: Can I customize color and hardness?

Yes, PVC can be produced in any RAL color and hardness from 55–95 Shore A.

Q4: What’s the typical lead time?

Production usually takes 2–3 weeks after sample approval.

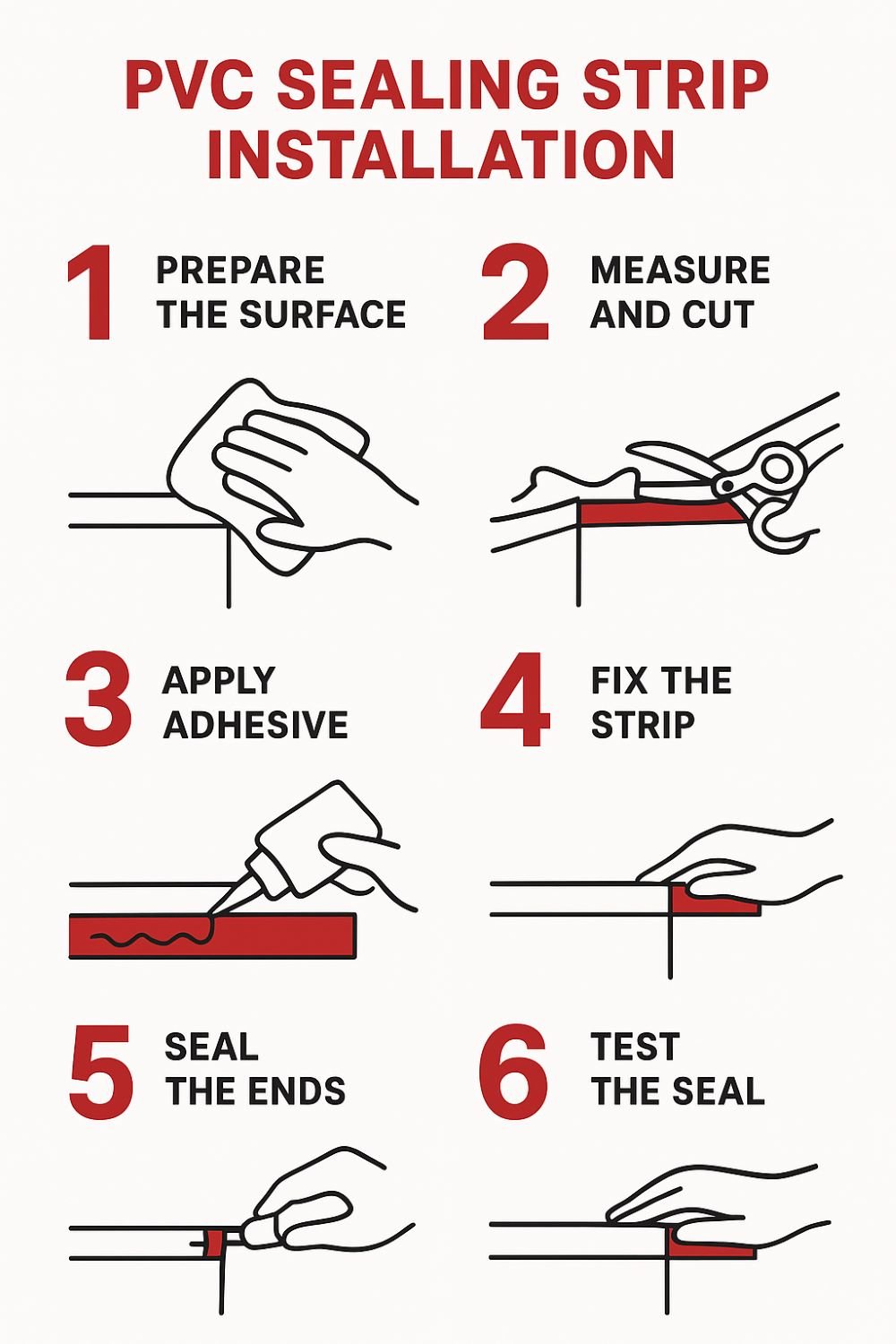

Q5: Do factories provide adhesive-backed strips?

Yes, many factories (including SW) offer 3M adhesive-backed profiles for easy installation.

10. How to Work Efficiently With a PVC Sealing Strip Factory

Provide a clear drawing or sample.

Specify the application environment (temperature, UV exposure, chemicals).

Confirm hardness and color codes.

Approve samples before mass production.

Establish inspection standards (tolerance, surface finish, color).

Agree on packaging and labeling requirements.

11. The Future of PVC Sealing Strips

Trends shaping the industry:

Eco-friendly plasticizers (phthalate-free, bio-based options)

Flame-retardant PVC for building compliance

Hybrid profiles (PVC + TPE or magnet layers)

Recycled material extrusion for sustainability goals

Smart sealing strips integrating light or sensor elements

Top factories like SW are investing in green extrusion technology, improving efficiency and recyclability while maintaining performance.

Choosing the right PVC sealing strip factory

Choosing the right PVC sealing strip factory is essential for ensuring reliable product performance, cost efficiency, and long-term partnership. Evaluate factories not only by price but also by technical expertise, quality consistency, and customization capability.

With its 20 years of specialization in extrusion and a strong global reputation, SW stands out as a trusted partner for OEM and brand owners seeking professional, durable, and tailored sealing solutions.

| Key Factor | What to Look For |

|---|---|

| Material quality | Non-toxic, UV-stable PVC |

| Technical equipment | Twin-screw extrusion, vacuum calibration |

| Customization | Hardness, color, co-extrusion |

| Quality control | ISO 9001, RoHS, REACH |

| Service | OEM/ODM support, quick sampling |

| Reputation | Proven export experience |

We have a PVC pipes factory of skilled engineers ready to support you in your product development journey from idea design to production.Any ideas about your product you can contact us freely,and our engineers will get back to you with a quote asap. Whatsapp +86 188 2072 7151

Who is Shuowei?

Since 2006, Shuowei is a professional extrusion profiles factory based in Guangdong, China. There are total about 51-100 people in our office. Shuowei PVC extrusion factory is committed to the design and production of extruded profiles, such as PVC pipes, PE trunking, PVC skirting line. Since its inception, we have won the wide recognition of the market and the deep trust of customers with our ingenious design, exquisite technology and the ultimate pursuit of quality.

Are you a manufacturer or a trader?

We are a Chinese top PVC extrusion profiles manufacturer and our factory is located in Huizhou. Our factory has a 16,000㎡ production base, 5+ automated extrusion profiles production lines, an annual production capacity of 30,000 tons, and serves more than 500 customers worldwide. Welcome to visit our factory!

What is your product range?

We pecialize in the design and production of high quality extrusion profiles,such as PVC pipe, ABS extrusion, PC lampshades, PVC skirting lines, PP trunking, PE profiles…

How long does the custom development process take?

We support custom extrusion products. The usual process has 4 steps: demand confirmation → 3D design/proofing → test certification → mass production (cycle 3-8 weeks).

Do you have any international certifications?

We have passed ISO 9001, CE, RoHS, SGS and other certifications, and meet the mainstream standards of Europe, America, the Middle East and Asia