When designing or renovating interiors, small details often define the overall look and performance of a space. Among these details, PVC skirting boards have become a popular choice due to their durability, cost-effectiveness, and aesthetic versatility. As a professional PVC skirting board manufacturer with over 20 years of experience, SW has helped countless customers select, install, and maintain skirting solutions tailored to their projects.

This blog provides a comprehensive technical guide on how to install PVC skirting boards properly and what usage precautions you need to consider. Whether you are a homeowner planning a DIY installation or a contractor working on a large-scale project, understanding the right techniques and care practices is essential for achieving the best results.

Image sourcing: swpvcextrusion.com

Why Choose PVC Skirting Board?

Before moving into installation methods, it’s important to understand why PVC skirting boards are an excellent option compared to alternatives like wood, MDF, or aluminum.

-

Waterproof and moisture resistant – PVC material does not swell, warp, or rot, making it perfect for kitchens, bathrooms, or damp environments.

-

Low maintenance – Unlike wood, it doesn’t require regular polishing or repainting.

-

Durable and impact resistant – Can withstand daily wear and tear from vacuum cleaners, mops, or furniture movement.

-

Versatile designs – Available in multiple colors, finishes, and sizes to match any interior theme.

-

Cost-effective – Affordable to purchase, install, and maintain.

Tools and Materials Required

Before starting installation, gather the following tools and supplies to ensure a smooth process:

-

PVC skirting board (cut to required length)

-

Measuring tape and pencil

-

Spirit level

-

Miter saw or fine-tooth handsaw

-

Adhesive (PVC-friendly glue) or screws and wall plugs

-

Drill and screwdriver (if using mechanical fixing)

-

Sandpaper (for smoothing cut edges)

-

Caulking gun and sealant (for joints and finishing)

-

Safety gear (gloves, goggles, mask if cutting indoors)

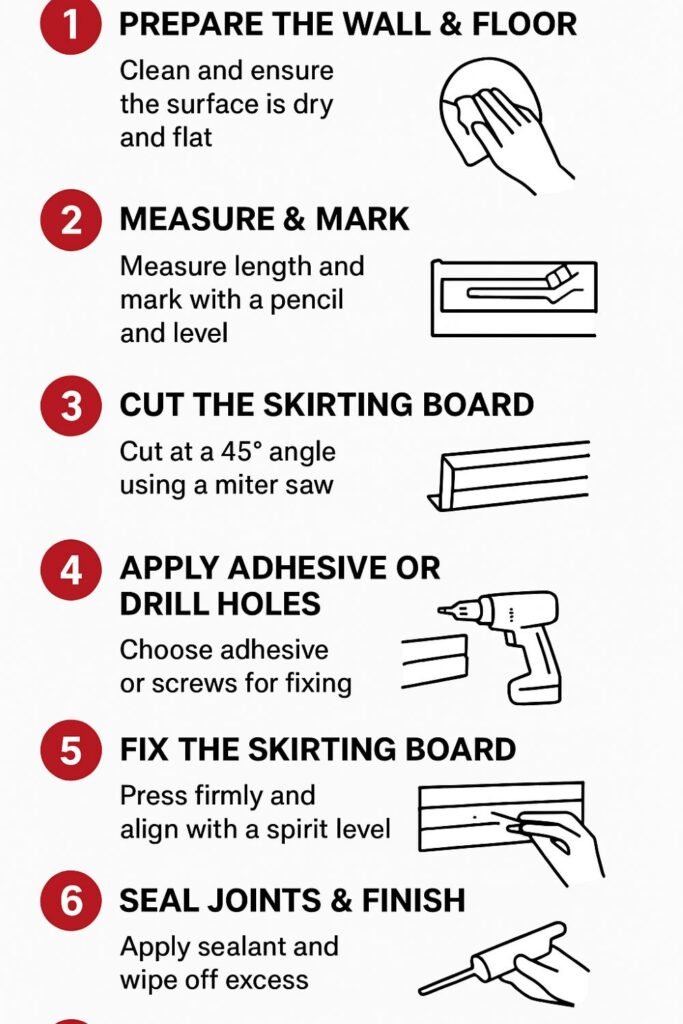

Step-by-Step PVC Skirting Board Installation

Installing PVC skirting board requires precision to ensure a seamless and professional look. Below is a detailed step-by-step guide.

Step 1: Preparing the Walls and Floor

-

Clean the wall and floor surface where the skirting will be fixed.

-

Remove dust, grease, or old adhesive.

-

Ensure the surface is dry, flat, and smooth for better adhesion.

Step 2: Measuring and Marking

-

Measure the length of each wall with a tape measure.

-

Transfer measurements to the PVC skirting board.

-

Use a pencil to mark cutting points clearly.

Step 3: Cutting the Skirting Boards

-

Use a miter saw or fine-tooth handsaw to cut boards to size.

-

For corners, cut at a 45° angle to create neat joints.

-

Smooth any rough edges with sandpaper.

Step 4: Fixing the Boards – Adhesive Method

-

Apply a strong PVC-compatible adhesive in zig-zag lines on the back of the skirting board.

-

Press the board firmly against the wall.

-

Use a spirit level to ensure it is straight.

-

Hold in place for a few minutes until adhesive begins to set.

Step 5: Fixing the Boards – Mechanical Method

-

Drill pilot holes along the length of the skirting board.

-

Insert wall plugs where screws will be positioned.

-

Fix the board with screws using a drill or screwdriver.

-

Conceal screw heads with matching caps or filler.

Step 6: Finishing Touches

-

Fill gaps between joints with sealant for a clean look.

-

Wipe away excess adhesive or caulk.

-

Check alignment once again with a spirit level.

-

Allow adhesive or sealant to cure fully before exposing to moisture.

Usage Precautions for PVC Skirting Boards

Proper usage extends the life and maintains the appearance of PVC skirting board. Below are essential precautions:

1. Avoid Excessive Heat

PVC is sensitive to high temperatures. Keep skirting boards away from direct heat sources such as radiators, heaters, or open flames. Prolonged exposure can cause warping or discoloration.

2. Regular Cleaning

-

Use a damp cloth or mild detergent solution to clean.

-

Avoid abrasive cleaning tools that may scratch the surface.

-

Do not use strong chemicals or solvents, as they may damage the PVC finish.

3. Handle with Care During Installation

-

Do not bend boards excessively, as this may cause cracking.

-

Always cut slowly with the right tools to prevent chipping.

4. Proper Adhesive Selection

-

Ensure the adhesive used is compatible with PVC.

-

Avoid water-based glues that may not bond effectively.

5. Moisture Precautions

Although PVC skirting boards are waterproof, always ensure the wall surface is dry before installation. Trapped moisture may affect adhesive strength.

6. Prevent Mechanical Damage

Take care when moving furniture or heavy equipment near the skirting. Though durable, repeated impact may cause scratches or dents.

Common Mistakes to Avoid

Even professional installers sometimes make errors. Here are mistakes to avoid when working with PVC skirting board:

-

Incorrect measurements – Always double-check before cutting.

-

Poor surface preparation – Dusty or greasy walls weaken adhesion.

-

Not leveling properly – Uneven skirting disrupts aesthetics.

-

Skipping expansion gaps – In large areas, leave small expansion gaps to accommodate natural movement.

-

Overusing adhesive – Too much glue causes uneven bonding and messy finishes.

Maintenance Tips for Long-Term Performance

-

Perform periodic cleaning to maintain shine.

-

Touch up joints with sealant if gaps appear over time.

-

Inspect boards yearly for any loosening or detachment.

-

Replace damaged sections immediately to maintain visual consistency.

Application Areas for PVC Skirting Board

Because of their waterproof and durable nature, PVC skirting boards are widely used in:

-

Residential spaces – Living rooms, bedrooms, kitchens, and bathrooms.

-

Commercial spaces – Offices, hotels, hospitals, and retail stores.

-

Public spaces – Schools, government buildings, and airports.

Why Work With SW – Your Reliable PVC Skirting Board Factory

With 20 years of expertise, SW has become a trusted PVC skirting board factory known for:

-

Custom extrusion capabilities to meet diverse project requirements.

-

High-quality materials ensuring durability and safety.

-

Variety of designs and finishes to suit different interior styles.

-

Technical support for installation and maintenance.

-

Global delivery for both small and large orders.

By choosing SW, you gain not only a reliable product but also professional after-sales support for long-term satisfaction.

Installing PVC skirting boards is a straightforward process

Installing PVC skirting board is a straightforward process if done with the right tools, careful preparation, and proper techniques. By following step-by-step installation instructions, applying the correct adhesives, and maintaining them properly, you can achieve a professional finish that enhances both function and style.

At SW, we pride ourselves on producing high-quality PVC skirting boards that meet the diverse needs of customers worldwide. Whether you’re designing a luxury residence, outfitting a commercial property, or planning a custom project, we provide solutions backed by 20 years of expertise in extrusion manufacturing.

If you are looking for reliable skirting solutions, contact SW today to learn more about our wide range of PVC skirting boards and custom services.

We have a PVC pipes factory of skilled engineers ready to support you in your product development journey from idea design to production.Any ideas about your product you can contact us freely,and our engineers will get back to you with a quote asap. Whatsapp +86 188 2072 7151

Who is Shuowei?

Since 2006, Shuowei is a professional extrusion profiles factory based in Guangdong, China. There are total about 51-100 people in our office. Shuowei PVC extrusion factory is committed to the design and production of extruded profiles, such as PVC pipes, PE trunking, PVC skirting line. Since its inception, we have won the wide recognition of the market and the deep trust of customers with our ingenious design, exquisite technology and the ultimate pursuit of quality.

Are you a manufacturer or a trader?

We are a Chinese top PVC extrusion profiles manufacturer and our factory is located in Huizhou. Our factory has a 16,000㎡ production base, 5+ automated extrusion profiles production lines, an annual production capacity of 30,000 tons, and serves more than 500 customers worldwide. Welcome to visit our factory!

What is your product range?

We pecialize in the design and production of high quality extrusion profiles,such as PVC pipe, ABS extrusion, PC lampshades, PVC skirting lines, PP trunking, PE profiles…

How long does the custom development process take?

We support custom extrusion products. The usual process has 4 steps: demand confirmation → 3D design/proofing → test certification → mass production (cycle 3-8 weeks).

Do you have any international certifications?

We have passed ISO 9001, CE, RoHS, SGS and other certifications, and meet the mainstream standards of Europe, America, the Middle East and Asia