Slipping hazards are one of the most common causes of workplace, household, and public facility accidents. To reduce the risks and improve safety, anti-slip strip is widely used in residential, commercial, and industrial spaces. Whether on stairs, walkways, ramps, or wet areas like bathrooms and swimming pools, the right anti-slip strip provides effective grip, enhances durability, and ensures a safer environment.

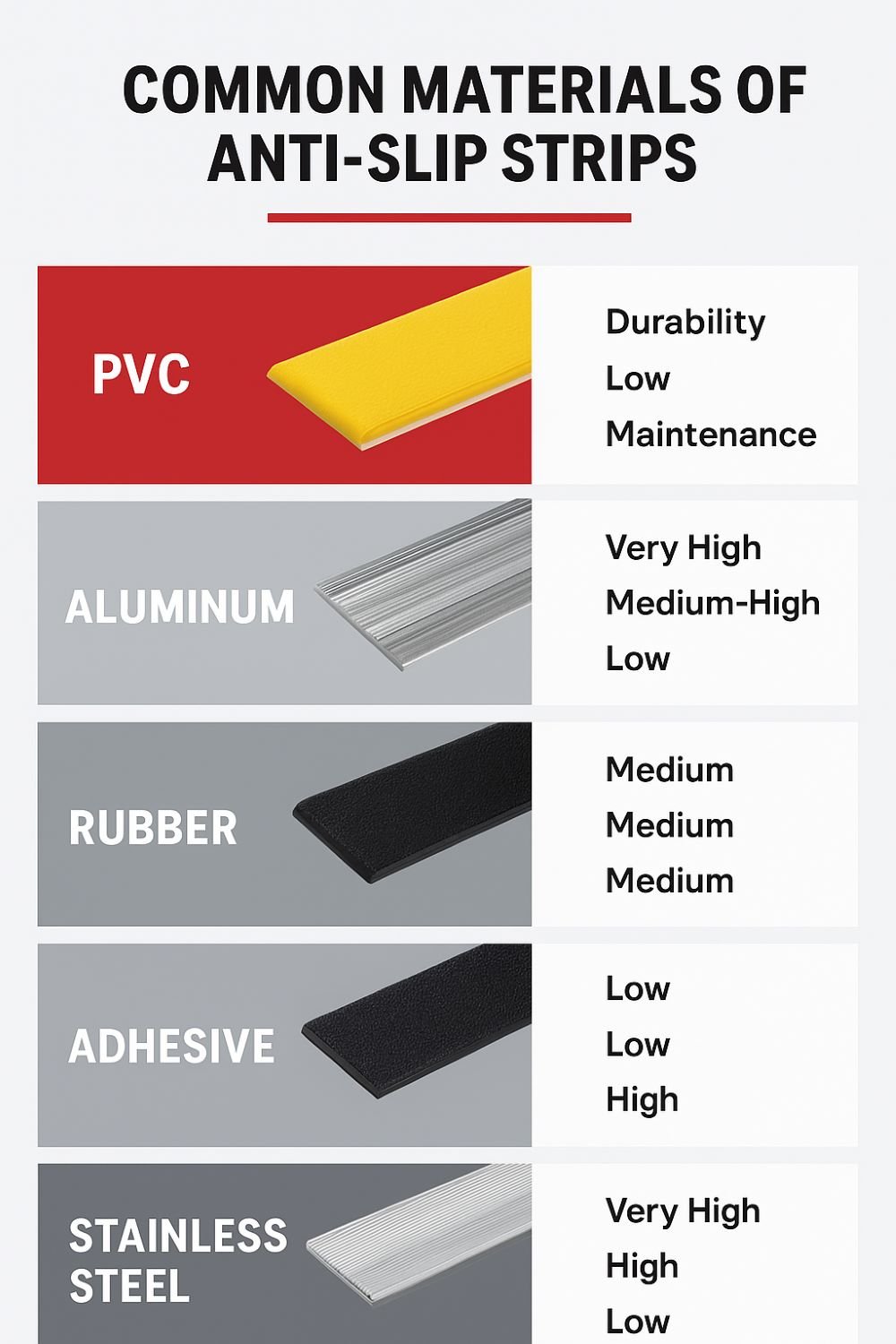

With many materials available—PVC, aluminum, rubber, stainless steel, and composite options—it can be challenging to decide which anti-slip strip is the best fit for your project. In this blog, we will explore different types of anti-slip strips, compare their advantages and limitations, and provide real-world application cases to help you choose wisely.

As a professional factory with 20 years of experience, SW specializes in extruded PVC anti-slip strips and offers tailored solutions for brands and projects worldwide.

Why Anti-Slip Strip is Essential

Before diving into materials, let’s understand why anti-slip strip is crucial:

Safety: Prevent slips and falls in high-traffic or wet areas.

Durability: Provide long-term performance even in demanding environments.

Compliance: Many industries require anti-slip solutions to meet safety standards.

Aesthetics: Improve the look of flooring and stairs while enhancing functionality.

Cost-effectiveness: Affordable compared to repairing accidents or installing new flooring.

Common Types of Anti-Slip Strip Materials

1. PVC Anti-Slip Strip

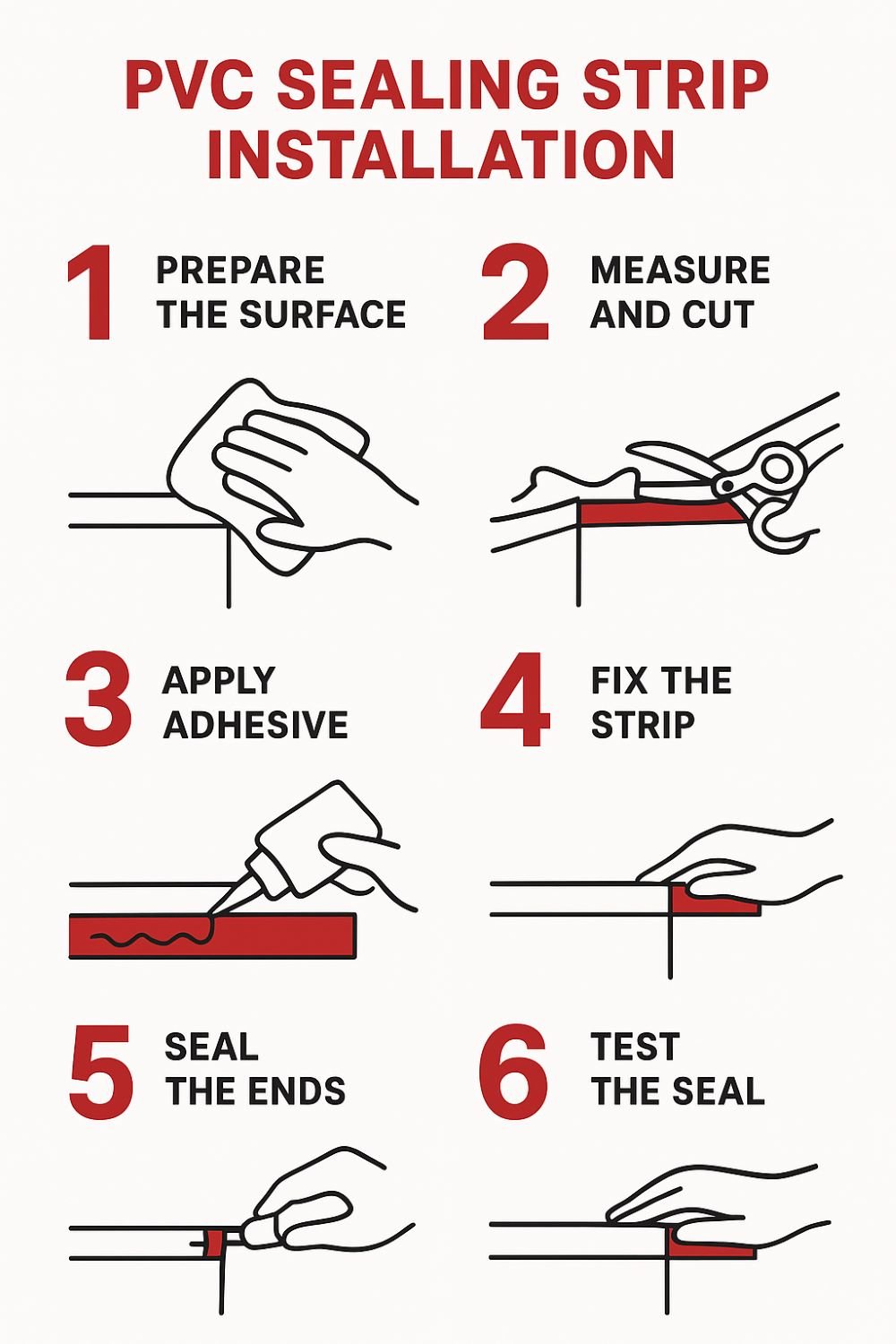

PVC anti-slip strips are among the most widely used due to their flexibility, affordability, and easy installation.

Advantages:

Lightweight and cost-effective.

Available in multiple colors and designs.

Resistant to moisture and chemicals.

Easy to extrude in custom profiles for specific applications.

Comfortable underfoot, making them ideal for residential and light commercial areas.

Limitations:

Less durable under heavy loads compared to metal alternatives.

May not perform well in extreme temperature conditions.

Applications:

Bathroom floors and showers.

Residential staircases.

Office and commercial flooring.

Public facilities requiring budget-friendly solutions.

2. Aluminum Anti-Slip Strip

Aluminum anti-slip strips are widely used in industrial and outdoor applications.

Advantages:

Extremely durable and long-lasting.

Resistant to heavy impacts and traffic.

Can be combined with abrasive inserts for maximum grip.

Suitable for both indoor and outdoor use.

Limitations:

Higher cost than PVC or rubber.

Requires more complex installation.

Applications:

Factories and warehouses.

Public stairs and ramps.

Transportation hubs like airports and train stations.

3. Rubber Anti-Slip Strip

Rubber anti-slip strips are popular for their soft texture and slip resistance.

Advantages:

Provides excellent traction.

Comfortable underfoot, reducing fatigue.

Shock-absorbing properties.

Easy to cut and install.

Limitations:

Can wear out faster in heavy traffic areas.

Less resistant to chemicals and UV exposure.

Applications:

Gyms and sports facilities.

Residential play areas.

Light commercial flooring.

4. Stainless Steel Anti-Slip Strip

Stainless steel anti-slip strips are premium solutions designed for demanding environments.

Advantages:

Highly durable and resistant to corrosion.

Withstands heavy loads and extreme weather.

Long service life with minimal maintenance.

Modern, sleek appearance.

Limitations:

High cost compared to other materials.

Less comfortable underfoot.

Applications:

Marine environments (boats, docks).

Industrial plants with chemical exposure.

Hospitals and laboratories requiring hygiene and durability.

5. Composite Anti-Slip Strip

Composite strips are made from blended materials like fiberglass and resins.

Advantages:

Excellent anti-slip performance.

Resistant to weather, chemicals, and fire.

Lightweight and durable.

Limitations:

Higher price point.

Not as widely available as PVC or aluminum.

Applications:

Outdoor decks and ramps.

Industrial flooring with chemical exposure.

High-traffic public facilities.

Material Comparison at a Glance

| Material | Durability | Comfort | Cost | Best Use Case |

|---|---|---|---|---|

| PVC | Moderate | High | Low | Homes, offices, light commercial areas |

| Aluminum | Very High | Low | High | Industrial, public spaces, outdoor stairs |

| Rubber | Moderate | High | Medium | Sports facilities, play areas |

| Stainless Steel | Very High | Low | Very High | Marine, chemical plants, hospitals |

| Composite | High | Medium | High | Outdoor decks, chemical-resistant flooring |

Application Case Studies

Case 1: Residential Building

A residential complex needed a cost-effective solution for slippery stairs and bathroom areas. PVC anti-slip strips were installed, offering both safety and aesthetics at a low cost. Residents appreciated the comfort and color-matching design.

Case 2: Industrial Warehouse

A warehouse with heavy forklift traffic chose aluminum anti-slip strips for staircases and ramps. These strips provided long-term durability, preventing accidents despite high daily loads.

Case 3: Gym Facility

A fitness center installed rubber anti-slip strips in its exercise area to reduce the risk of slipping while maintaining comfort for users. The strips also helped absorb impact from dropped weights.

Case 4: Marine Dock

For a busy marina, stainless steel anti-slip strips were installed on walkways and stairs. The corrosion resistance ensured long service life even in constant contact with saltwater.

Case 5: Outdoor Public Park

A city park authority selected composite anti-slip strips for ramps and pedestrian bridges. The strips resisted weather changes, heavy usage, and provided fire resistance.

How to Choose the Right Anti-Slip Strip

Identify the environment – indoor vs. outdoor, wet vs. dry.

Estimate load and traffic – light residential or heavy industrial.

Consider durability requirements – long-term investment vs. short-term budget.

Evaluate comfort and aesthetics – residential comfort vs. industrial toughness.

Budget planning – balance cost-effectiveness with safety performance.

Consult a professional manufacturer – experienced suppliers like SW provide expert guidance and custom solutions.

Why Choose SW for PVC Anti-Slip Strips

At SW, we have been specializing in PVC anti-slip strip for over 20 years. Our advantages include:

Advanced extrusion equipment for precision manufacturing.

Customizable designs, colors, and profiles.

High-quality raw materials for durability and performance.

Collaboration with brands worldwide to deliver tailored solutions.

Strict quality control to meet international safety standards.

Whether you need anti-slip strips for residential, commercial, or industrial use, SW is your trusted partner for PVC anti-slip strips.

Selecting the right anti-slip strip

Selecting the right anti-slip strip is essential for safety, durability, and cost-effectiveness. While aluminum, rubber, stainless steel, and composite strips all have their unique benefits, PVC anti-slip strips remain one of the most versatile and economical choices.

By comparing materials and understanding real-world applications, you can make a smarter choice that meets your project’s needs. For reliable, customizable, and affordable solutions, SW’s PVC anti-slip strips offer a perfect balance of performance and value.

We have a PVC pipes factory of skilled engineers ready to support you in your product development journey from idea design to production.Any ideas about your product you can contact us freely,and our engineers will get back to you with a quote asap. Whatsapp +86 188 2072 7151

Who is Shuowei?

Since 2006, Shuowei is a professional extrusion profiles factory based in Guangdong, China. There are total about 51-100 people in our office. Shuowei PVC extrusion factory is committed to the design and production of extruded profiles, such as PVC pipes, PE trunking, PVC skirting line. Since its inception, we have won the wide recognition of the market and the deep trust of customers with our ingenious design, exquisite technology and the ultimate pursuit of quality.

Are you a manufacturer or a trader?

We are a Chinese top PVC extrusion profiles manufacturer and our factory is located in Huizhou. Our factory has a 16,000㎡ production base, 5+ automated extrusion profiles production lines, an annual production capacity of 30,000 tons, and serves more than 500 customers worldwide. Welcome to visit our factory!

What is your product range?

We pecialize in the design and production of high quality extrusion profiles,such as PVC pipe, ABS extrusion, PC lampshades, PVC skirting lines, PP trunking, PE profiles…

How long does the custom development process take?

We support custom extrusion products. The usual process has 4 steps: demand confirmation → 3D design/proofing → test certification → mass production (cycle 3-8 weeks).

Do you have any international certifications?

We have passed ISO 9001, CE, RoHS, SGS and other certifications, and meet the mainstream standards of Europe, America, the Middle East and Asia