In modern construction, safety and durability are top priorities. Floors, stairs, and walkways present potential hazards if left untreated, especially in areas exposed to moisture or heavy foot traffic. This is where the PVC anti-slip strip becomes an essential product.

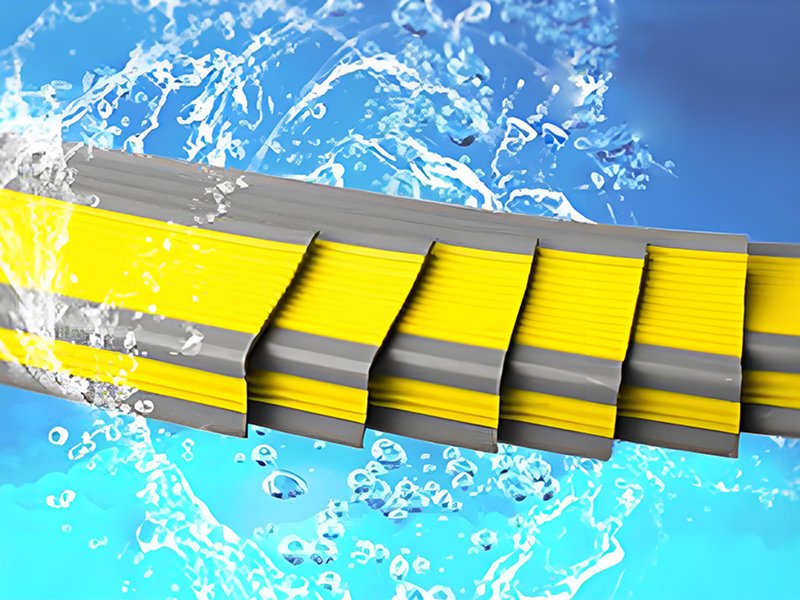

A PVC anti-slip strip is a specialized extrusion designed to provide grip and safety. It prevents slips and falls by offering a textured or coated surface that increases friction underfoot. Widely used in commercial buildings, public facilities, residential spaces, and industrial environments, these strips combine practicality with cost-efficiency.

At SW, we are a professional extrusion factory with more than 20 years of manufacturing experience in PVC anti-slip strips. We provide OEM and custom solutions to clients worldwide. This blog will explain how PVC anti-slip strips are produced, the customization process, their benefits, and important quality considerations for buyers.

Why Choose a PVC Anti-Slip Strip?

Before diving into the manufacturing process, let’s explore why PVC anti-slip strips are so widely chosen over alternatives such as aluminum, stainless steel, or rubber.

-

Durability: PVC material offers resistance to wear, impact, and moisture.

-

Cost-effectiveness: Compared with metal strips, PVC strips are affordable while still providing safety.

-

Flexibility in design: Extrusion allows custom shapes, sizes, and textures.

-

Color and finish options: PVC anti-slip strips can be manufactured in a wide variety of colors to match interiors or provide safety highlights.

-

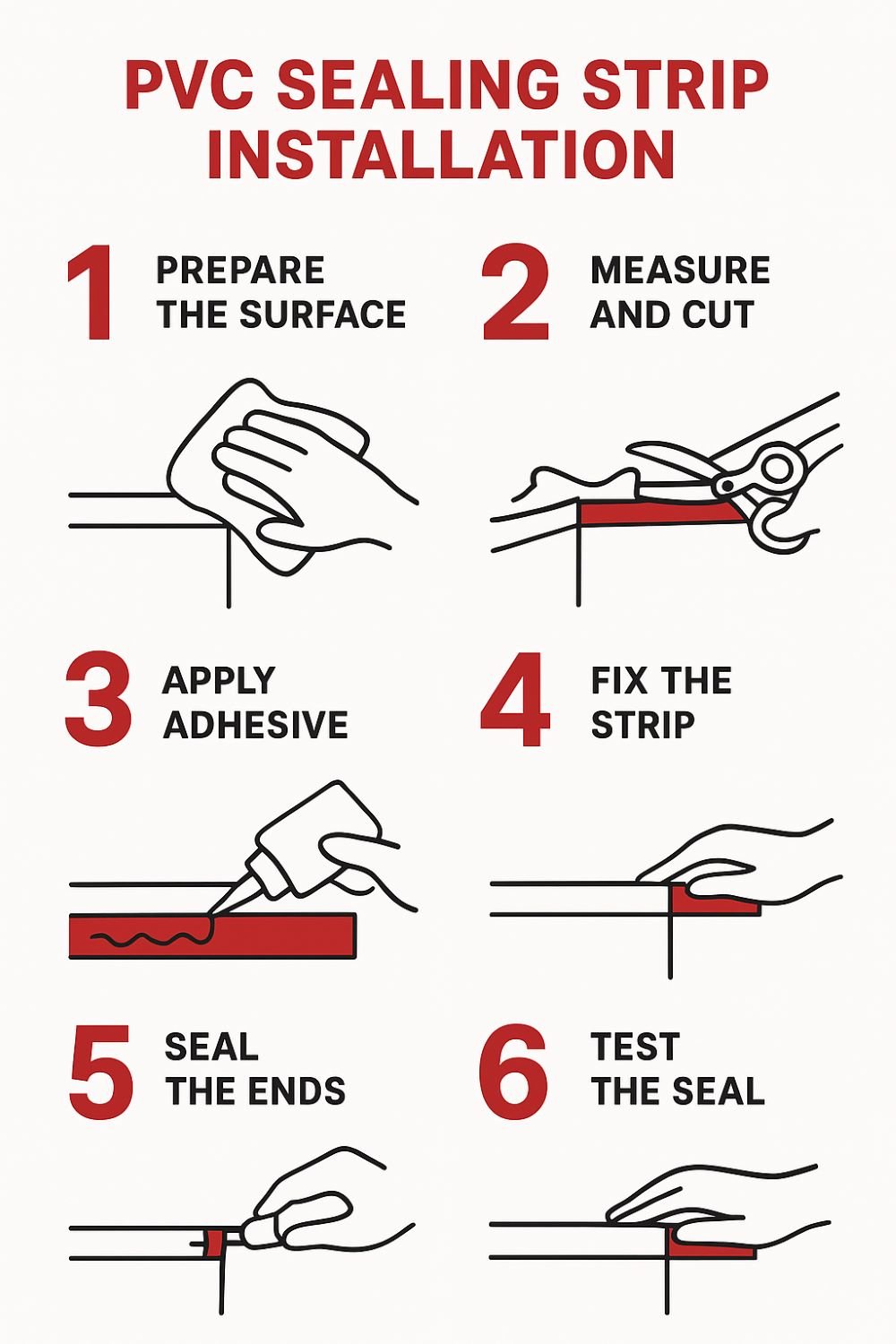

Easy installation: Lightweight and versatile, PVC strips are easy to cut, fit, and fix.

These benefits make PVC anti-slip strips a smart investment for staircases, ramps, bathrooms, public corridors, and commercial flooring.

The Production Process of Custom PVC Anti-Slip Strips

At SW factory, producing a custom PVC anti-slip strip follows a highly controlled extrusion process. Below is a step-by-step guide to the typical manufacturing procedure.

1. Raw Material Selection and Preparation

The process begins with selecting high-quality PVC resin. Depending on the client’s needs, additives are mixed with the resin to achieve specific properties:

-

Plasticizers for flexibility.

-

Stabilizers for heat and UV resistance.

-

Pigments for color matching.

-

Fillers for cost and density control.

These ingredients are precisely measured and blended to create the formulation for extrusion.

2. Compounding and Mixing

The resin blend is fed into a high-speed mixer, where it is heated and blended into a uniform compound. This ensures consistent quality and material properties across all batches.

3. Extrusion Process

The compounded PVC material is fed into an extrusion machine, where it is heated to a molten state. The molten material passes through a specially designed die that shapes it into a strip.

-

The die design is crucial: It defines the dimensions, profile, and anti-slip surface pattern (e.g., ridges, grooves, dots).

-

Cooling tanks solidify the extruded strip, preserving its shape.

-

Precision cutting machines then cut the strips into required lengths.

4. Surface Treatment and Texturing

The anti-slip function is created by surface finishing techniques:

-

Embossing: Creates raised ridges or textured surfaces.

-

Coating: Application of anti-slip materials, such as grit or rubberized layers.

-

UV Coating: Protects against fading and outdoor weathering.

This step can be fully customized to meet safety regulations or design preferences.

5. Color Customization

One advantage of PVC extrusion is the ability to customize colors. Anti-slip strips may be manufactured in bright yellow for hazard awareness, black or gray for modern interiors, or transparent/neutral finishes for subtle designs. At SW, we match Pantone colors for OEM customers.

6. Quality Control and Testing

Every batch of PVC anti-slip strip undergoes strict testing:

-

Slip resistance testing under wet and dry conditions.

-

Impact and load testing for durability.

-

Dimensional accuracy checks.

-

Color consistency inspection.

This ensures every strip meets international safety and quality standards.

7. Packaging and Delivery

Finally, strips are bundled, labeled, and packaged according to customer requirements. Options include rolls, bundles, or individually wrapped strips for retail markets.

Customization Options for PVC Anti-Slip Strips

When you partner with a professional PVC anti-slip strip factory like SW, customization is one of the key advantages. Customers can specify:

-

Profile and Shape: Flat strips, rounded edges, stair nosing profiles, or T-shaped profiles.

-

Dimensions: Thickness, width, and length according to project needs.

-

Colors: Matching branding, safety colors, or natural tones.

-

Surface Texture: Smooth, ribbed, embossed, or coated.

-

Installation Method: Self-adhesive backing, screw-fixed, or clip-in systems.

Customization allows architects, builders, and designers to integrate safety solutions seamlessly with aesthetics.

Applications of PVC Anti-Slip Strips

PVC anti-slip strips are versatile and can be used in various sectors:

-

Residential Buildings: Stairs, bathrooms, kitchens, and children’s rooms.

-

Commercial Spaces: Shopping malls, schools, office lobbies.

-

Public Infrastructure: Train stations, airports, hospitals.

-

Industrial Areas: Factories, warehouses, loading docks.

-

Outdoor Spaces: Swimming pools, ramps, playgrounds (with UV-resistant PVC).

At SW, we also work with OEM brands who integrate PVC anti-slip strips into complete flooring systems.

Advantages of Working with a Professional PVC Anti-Slip Strip Factory

Not all suppliers provide the same level of quality and service. Choosing the right PVC anti-slip strip factory ensures safety, reliability, and cost savings. Here’s what SW provides:

-

20 years of manufacturing expertise in PVC extrusion.

-

OEM/ODM services for international clients.

-

Advanced extrusion lines for precision and efficiency.

-

Strict quality control with international testing standards.

-

Custom solutions for different industries and markets.

-

On-time delivery with global logistics support.

Common Mistakes to Avoid When Ordering PVC Anti-Slip Strips

-

Choosing the wrong material: Always verify PVC is the right fit compared with rubber or metal alternatives.

-

Ignoring slip resistance testing: Not all strips are tested under wet conditions.

-

Overlooking installation methods: Ensure the strip design fits your flooring or stair type.

-

Selecting low-quality suppliers: Cheap strips may crack, fade, or lose adhesion quickly.

Future Trends in PVC Anti-Slip Strips

The market for PVC anti-slip strips continues to grow. New trends include:

-

Eco-friendly PVC with recycled content.

-

Transparent anti-slip strips for minimalist designs.

-

Smart strips with embedded reflective lines for safety in low light.

-

Improved UV stability for outdoor applications.

SW is continuously innovating to meet these demands, ensuring our clients stay ahead of the competition.

a trusted partner in PVC anti-slip strip production

A PVC anti-slip strip may seem like a small detail, but in terms of safety, aesthetics, and functionality, it plays a big role. From raw material selection to extrusion, surface treatment, and customization, the production process ensures that every strip is reliable, durable, and suited for its intended application.

At SW, with 20 years of manufacturing experience, we specialize in producing and customizing PVC anti-slip strips that meet international quality standards. Whether you are an architect, distributor, or contractor, we provide tailored solutions to enhance safety and design.

If you’re looking for a trusted partner in PVC anti-slip strip production, SW is your reliable factory in China.

We have a PVC pipes factory of skilled engineers ready to support you in your product development journey from idea design to production.Any ideas about your product you can contact us freely,and our engineers will get back to you with a quote asap. Whatsapp +86 188 2072 7151

Who is Shuowei?

Since 2006, Shuowei is a professional extrusion profiles factory based in Guangdong, China. There are total about 51-100 people in our office. Shuowei PVC extrusion factory is committed to the design and production of extruded profiles, such as PVC pipes, PE trunking, PVC skirting line. Since its inception, we have won the wide recognition of the market and the deep trust of customers with our ingenious design, exquisite technology and the ultimate pursuit of quality.

Are you a manufacturer or a trader?

We are a Chinese top PVC extrusion profiles manufacturer and our factory is located in Huizhou. Our factory has a 16,000㎡ production base, 5+ automated extrusion profiles production lines, an annual production capacity of 30,000 tons, and serves more than 500 customers worldwide. Welcome to visit our factory!

What is your product range?

We pecialize in the design and production of high quality extrusion profiles,such as PVC pipe, ABS extrusion, PC lampshades, PVC skirting lines, PP trunking, PE profiles…

How long does the custom development process take?

We support custom extrusion products. The usual process has 4 steps: demand confirmation → 3D design/proofing → test certification → mass production (cycle 3-8 weeks).

Do you have any international certifications?

We have passed ISO 9001, CE, RoHS, SGS and other certifications, and meet the mainstream standards of Europe, America, the Middle East and Asia