When it comes to flooring safety, PVC anti-slip strip plays an essential role in reducing the risk of accidents in residential, commercial, and industrial environments. These strips are designed to provide additional grip on stairs, ramps, walkways, and other potentially hazardous surfaces. Whether you are a homeowner aiming to make your staircase safer, or a facility manager implementing occupational safety standards, knowing how to install and maintain PVC anti-slip strips is crucial.

At SW, with over 20 years of expertise in manufacturing PVC anti-slip strips, we provide not only high-quality products but also technical guidance to ensure customers can use them correctly and effectively. This blog explores installation techniques, usage precautions, and best practices for maintaining PVC anti-slip strips.

Why Choose PVC Anti-Slip Strip?

Before diving into installation, it is important to understand why PVC is one of the most popular materials for anti-slip applications:

-

Durability: PVC anti-slip strips are resistant to moisture, corrosion, and chemical exposure.

-

Flexibility: Unlike metal strips, PVC anti-slip strips are easy to cut and fit into customized spaces.

-

Cost-Effectiveness: They are more affordable compared to aluminum or stainless steel strips.

-

Comfort: PVC strips provide softer contact underfoot, making them ideal for homes and workplaces.

-

Aesthetic Options: Available in a variety of colors and finishes, PVC anti-slip strips can blend with different flooring styles.

Tools and Materials Needed

Before you start installation, prepare the following tools and materials:

-

PVC anti-slip strips (cut to required length)

-

Measuring tape and marker

-

Utility knife or PVC cutter

-

Adhesive (PVC-compatible glue or double-sided industrial tape)

-

Screws and drill (if mechanical fastening is needed)

-

Cleaning supplies (mild detergent, cloth, and brush)

-

Personal protective equipment (gloves, goggles, mask)

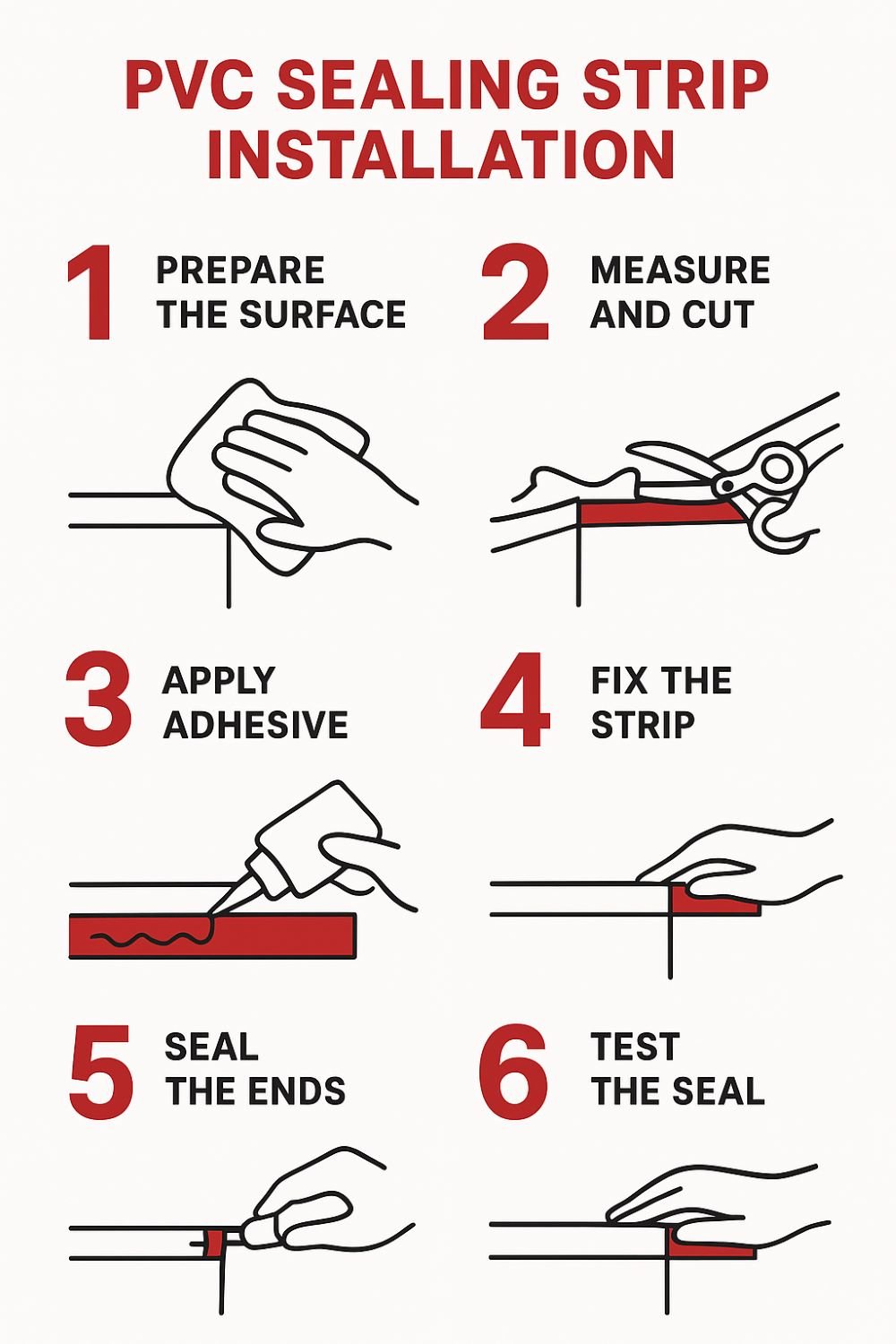

Step-by-Step PVC anti-slip strip Installation Process

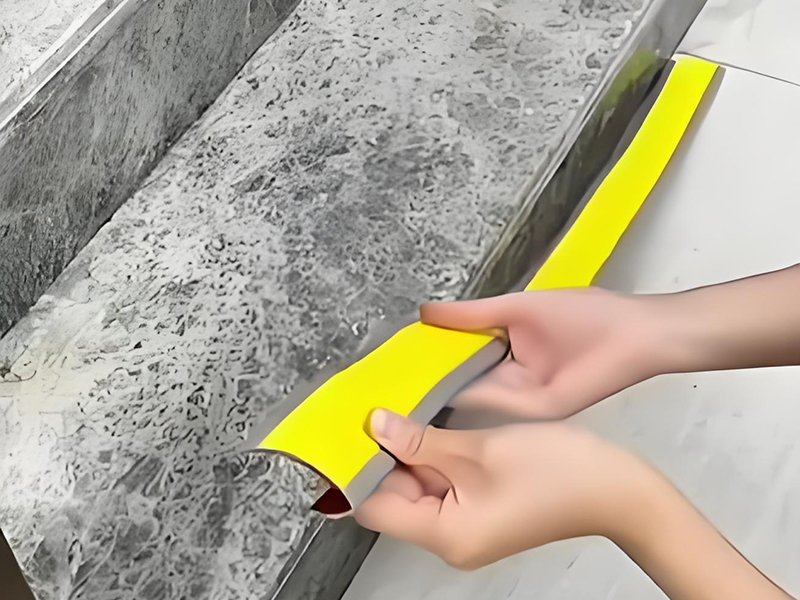

Step 1: Surface Preparation

-

Ensure the installation surface is clean, dry, and free of dust, grease, or oil.

-

Uneven flooring should be leveled before applying the PVC anti-slip strip.

-

Use a mild detergent and let the surface dry completely.

Step 2: Measurement and Cutting

-

Measure the area where the PVC anti-slip strip will be installed.

-

Mark the measurements on the strip using a marker.

-

Use a PVC cutter or a sharp utility knife to cut the strip to size.

-

For corners or angled staircases, cut at a 45° angle for a neat finish.

Step 3: Adhesive Application

-

Apply PVC-compatible adhesive evenly on the back of the strip.

-

Alternatively, use industrial-grade double-sided tape for lighter applications.

-

For high-traffic areas, mechanical fastening with screws is recommended.

Step 4: Fixing the Strip

-

Carefully align the PVC anti-slip strip with the marked position.

-

Press firmly along the entire length to ensure proper adhesion.

-

If using screws, drill pilot holes and secure the strip at regular intervals.

Step 5: Final Inspection

-

Check for air bubbles or loose edges.

-

Press down again on weak spots to ensure strong adhesion.

-

Clean any adhesive residue with a damp cloth.

Usage Precautions

To maximize the safety and durability of your PVC anti-slip strip, keep these considerations in mind:

-

Avoid Extreme Heat Exposure

-

PVC can warp or lose adhesion when exposed to direct heat sources. Do not install strips near open flames, heaters, or hot machinery.

-

-

Regular Cleaning

-

Clean with mild soap and water.

-

Avoid abrasive cleaners, harsh chemicals, or steel brushes which may damage the surface.

-

-

Periodic Inspection

-

Check strips regularly for signs of loosening, wear, or damage.

-

Replace damaged strips promptly to maintain safety.

-

-

Moisture Control

-

While PVC is resistant to water, ensure proper drainage in wet areas to prevent mold and mildew around the edges.

-

-

Proper Adhesive Selection

-

Always use adhesives specifically designed for PVC. Incompatible adhesives can cause strip peeling.

-

Application Areas of PVC Anti-Slip Strip

Residential:

-

Staircases, bathroom floors, kitchens, and balconies.

Commercial:

-

Office buildings, shopping malls, schools, and hospitals.

Industrial:

-

Factories, warehouses, ramps, and loading areas.

Public Spaces:

-

Train stations, bus terminals, gyms, and swimming pools.

Common Mistakes to Avoid

-

Incorrect Surface Preparation: Installing PVC anti-slip strips on dirty or oily surfaces reduces adhesion.

-

Skipping Edge Sealing: Exposed edges can lift over time; sealing with adhesive prevents this.

-

Using the Wrong Tools: Poorly cut strips may result in uneven surfaces and safety hazards.

-

Ignoring Load Requirements: For heavy-duty applications, always reinforce strips with screws.

Maintenance Best Practices

-

Weekly Cleaning: Mop or wipe the strips to remove dust and debris.

-

Monthly Inspection: Check adhesion and surface texture for signs of wear.

-

Annual Replacement: In high-traffic areas, consider replacing strips annually for maximum effectiveness.

Why Partner with SW for PVC Anti-Slip Strip?

As a professional PVC anti-slip strip manufacturer with 20 years of industry experience, SW ensures:

-

High-quality, durable products.

-

Custom extrusion solutions for different applications.

-

OEM & ODM services tailored to client requirements.

-

Strict quality control and international standards compliance.

Our expertise not only lies in manufacturing but also in helping clients choose, install, and maintain their anti-slip safety solutions.

Installing and maintaining PVC anti-slip strip

Installing and maintaining PVC anti-slip strip is an effective way to enhance safety and reduce accidents in both residential and commercial environments. By following proper installation techniques and usage precautions, you can extend the lifespan of your strips and ensure maximum protection.

For businesses and homeowners alike, partnering with an experienced PVC anti-slip strip factory like SW guarantees long-term value, safety, and professional support.

We have a PVC pipes factory of skilled engineers ready to support you in your product development journey from idea design to production.Any ideas about your product you can contact us freely,and our engineers will get back to you with a quote asap. Whatsapp +86 188 2072 7151

Who is Shuowei?

Since 2006, Shuowei is a professional extrusion profiles factory based in Guangdong, China. There are total about 51-100 people in our office. Shuowei PVC extrusion factory is committed to the design and production of extruded profiles, such as PVC pipes, PE trunking, PVC skirting line. Since its inception, we have won the wide recognition of the market and the deep trust of customers with our ingenious design, exquisite technology and the ultimate pursuit of quality.

Are you a manufacturer or a trader?

We are a Chinese top PVC extrusion profiles manufacturer and our factory is located in Huizhou. Our factory has a 16,000㎡ production base, 5+ automated extrusion profiles production lines, an annual production capacity of 30,000 tons, and serves more than 500 customers worldwide. Welcome to visit our factory!

What is your product range?

We pecialize in the design and production of high quality extrusion profiles,such as PVC pipe, ABS extrusion, PC lampshades, PVC skirting lines, PP trunking, PE profiles…

How long does the custom development process take?

We support custom extrusion products. The usual process has 4 steps: demand confirmation → 3D design/proofing → test certification → mass production (cycle 3-8 weeks).

Do you have any international certifications?

We have passed ISO 9001, CE, RoHS, SGS and other certifications, and meet the mainstream standards of Europe, America, the Middle East and Asia