In the world of modern manufacturing, construction, and automotive sealing, PVC sealing strips have become one of the most widely used components for protecting, sealing, and insulating. Their flexibility, cost-effectiveness, and durability make them a top choice across industries—from window and door frames to machinery, refrigerators, and vehicles.

At SW, we have over 20 years of experience as a professional PVC sealing strips factory, specializing in custom extruded PVC sealing strips designed to meet the needs of diverse applications. This guide explains the functions, advantages, and various uses of PVC sealing strips, helping customers make informed decisions when selecting the best solution for their projects.

1. What Are PVC Sealing Strips?

A PVC sealing strip is a flexible extruded plastic component made primarily from polyvinyl chloride (PVC). It’s designed to seal gaps, prevent water, air, or dust leaks, and reduce vibration or noise.

PVC’s combination of elasticity, chemical resistance, and thermal stability makes it an ideal choice for sealing applications in both residential and industrial environments. Depending on the design, PVC sealing strips can be solid, hollow, foamed, or co-extruded with other materials for added performance.

Key Features of PVC Sealing Strips

Excellent weather resistance

Waterproof and airtight performance

UV resistant and suitable for outdoor use

Flame retardant and temperature stable

Compatible with adhesives, screws, or mechanical fasteners

Available in custom shapes, colors, and hardness levels

At SW PVC sealing strips factory, we can customize the durometer (hardness), color, and cross-section to perfectly match your specific requirements.

2. Primary Functions of PVC Sealing Strips

PVC sealing strips serve several essential functions across industries:

2.1. Sealing

Their main function is to create an airtight or watertight seal between two surfaces, such as doors, windows, or machine panels. This prevents water ingress, dust infiltration, and air leakage, ensuring energy efficiency and protection against external elements.

2.2. Insulation

PVC sealing strips help provide thermal and sound insulation, which is especially valuable in buildings and vehicles. They block heat transfer and absorb sound vibrations, creating quieter and more energy-efficient environments.

2.3. Vibration Damping

In machinery or automotive settings, PVC sealing strips act as shock absorbers, reducing vibration and noise caused by mechanical movement.

2.4. Protection

PVC strips also serve as protective barriers, covering sharp edges or metal surfaces to prevent injuries or wear. They help increase the lifespan of mechanical components by reducing friction and mechanical stress.

2.5. Aesthetic Enhancement

With smooth finishes and customizable colors, PVC sealing strips can also serve decorative functions, improving the appearance of installations like window frames, doors, or furniture edges.

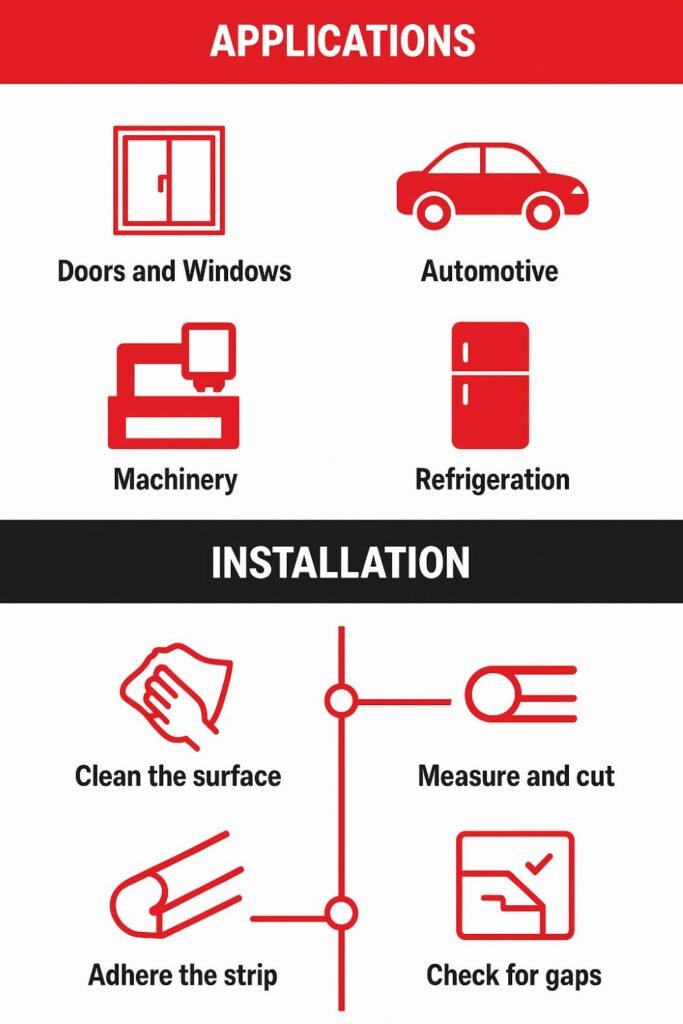

3. Applications of PVC Sealing Strips

PVC sealing strips are used in a wide range of applications due to their versatility and excellent sealing performance.

3.1. Door and Window Sealing

PVC sealing strips are used to seal the gaps between doors or windows and their frames, preventing drafts, water leakage, and noise. These are often extruded with a soft sealing lip for flexibility and tight contact.

3.2. Automotive Sealing

Automotive manufacturers use PVC sealing strips in doors, trunks, hoods, and windshields to ensure weatherproofing and vibration control. The flexibility of PVC makes it ideal for vehicle assembly, where precise sealing is critical.

3.3. Refrigeration and Appliances

PVC sealing strips are widely used in refrigerators, freezers, and other appliances to maintain temperature and reduce energy loss. The material’s resistance to cold and humidity ensures long-lasting performance.

3.4. Industrial Machinery

Industrial equipment often uses PVC sealing strips to block dust and oil, reduce vibration, and protect moving components. Their resistance to chemicals and wear makes them suitable for factories and mechanical systems.

3.5. Construction and Architecture

In the construction industry, PVC sealing strips are installed around glass panels, partitions, and flooring systems to ensure airtight, watertight, and aesthetic sealing solutions.

4. Advantages of PVC Sealing Strips

PVC sealing strips offer numerous benefits that make them one of the most preferred sealing materials in the market.

4.1. Excellent Sealing Performance

PVC’s flexibility and ability to conform to uneven surfaces provide excellent sealing performance, even in harsh weather conditions.

4.2. Cost Efficiency

Compared to rubber or silicone, PVC sealing strips are more affordable to produce and maintain, offering a great cost-performance ratio.

4.3. Durability

PVC is naturally resistant to corrosion, UV rays, and moisture, ensuring a long service life both indoors and outdoors.

4.4. Versatility

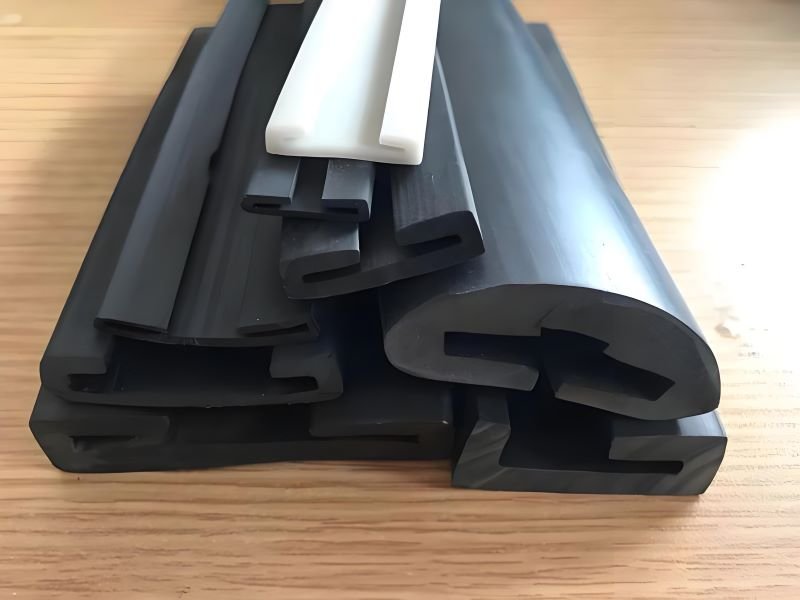

PVC sealing strips can be custom extruded into almost any profile—U-shapes, T-shapes, bulb seals, or flat gaskets—to meet specific application requirements.

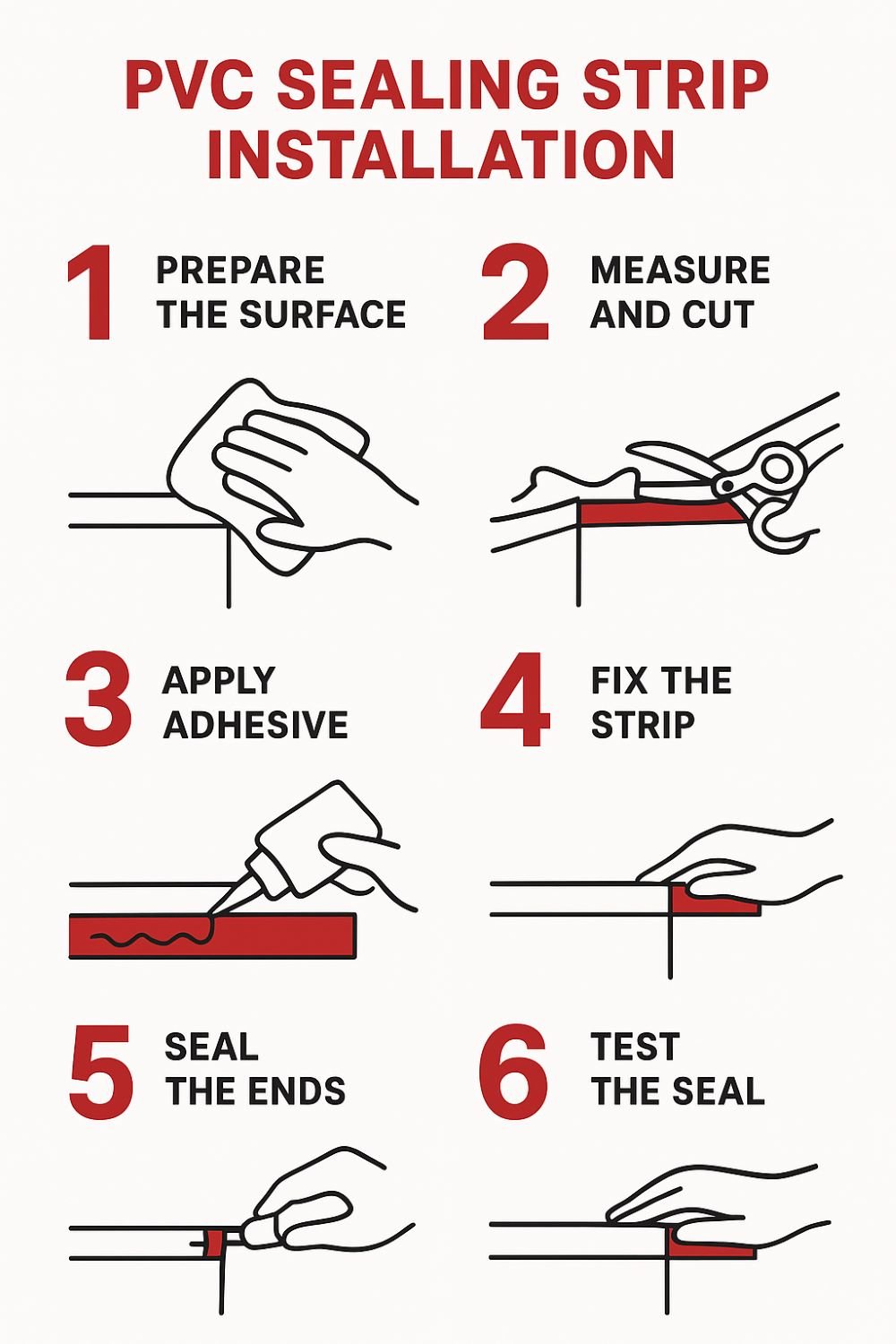

4.5. Easy Installation

These strips can be easily cut, glued, or screwed into place, making them convenient for on-site installation and replacement.

4.6. Low Maintenance

PVC sealing strips require minimal maintenance. Simple cleaning keeps them looking and performing like new for years.

5. Types of PVC Sealing Strips

Depending on the design and purpose, PVC sealing strips can be categorized as:

| Type | Description | Typical Applications |

|---|---|---|

| Solid PVC Strip | Dense and durable, ideal for structural sealing | Doors, windows, machinery |

| Foamed PVC Strip | Lightweight, excellent for sound insulation | Automotive, construction |

| Co-Extruded Strip | Combines hard and soft PVC layers | Doors, windows, appliances |

| Magnetic PVC Strip | Contains magnetic material for tight closure | Refrigerators, cabinets |

| Adhesive-backed Strip | Features self-adhesive tape for quick installation | DIY applications |

At SW PVC sealing strips factory, we produce all these variations and can customize based on your drawings, hardness range (60–95 Shore A), and color requirements.

6. How PVC Sealing Strips Are Manufactured

At SW, our PVC sealing strips production process involves several key steps to ensure consistency and high quality.

6.1. Material Preparation

PVC resin, plasticizers, stabilizers, and additives are mixed to form a flexible compound suitable for extrusion.

6.2. Extrusion

The compound is heated and extruded through a die, shaping it into the desired sealing profile. The extrusion temperature and speed are precisely controlled for accuracy.

6.3. Cooling and Calibration

The newly formed strip passes through a cooling and calibration system, maintaining dimensional stability and surface smoothness.

6.4. Cutting and Coiling

The strips are cut to the required length or rolled into coils for easier transportation and installation.

6.5. Quality Inspection

Each batch undergoes quality control tests for hardness, color consistency, surface finish, and sealing performance before packaging.

7. How to Choose the Right PVC Sealing Strips

When selecting the ideal PVC sealing strip, consider the following factors:

7.1. Application Environment

Determine whether the strip will be exposed to heat, UV light, or chemicals. PVC performs well in moderate to harsh environments, but additional additives may be needed for extreme conditions.

7.2. Shape and Size

Choose the right profile based on your sealing gap. Custom extruded shapes can be designed to match precise dimensions.

7.3. Hardness

The durometer (Shore A) affects flexibility. Soft PVC (60–75 Shore A) provides excellent sealing, while harder PVC offers structural support.

7.4. Color and Finish

PVC sealing strips can be produced in white, black, gray, or transparent finishes to match the aesthetic of the application.

7.5. Installation Method

Decide whether you need adhesive-backed, magnetic, or mechanical fixing types depending on how the strip will be mounted.

8. Real-World Application Examples

Example 1: Automotive Door Sealing

A car manufacturer used SW’s co-extruded PVC sealing strip with soft lips for superior noise reduction and water sealing. The result was a 20% improvement in cabin quietness and durability.

Example 2: Refrigerator Door Seal

A home appliance brand adopted SW’s magnetic PVC sealing strips for tight, energy-efficient door closure. The magnetic design improved insulation and reduced energy costs.

Example 3: Industrial Equipment Enclosure

In a machinery project, PVC sealing strips were used to prevent oil leakage and vibration in heavy equipment, significantly increasing lifespan and safety.

Example 4: Building Window Frames

An architectural firm used SW’s clear PVC sealing strips in glass façade installations, achieving both weatherproofing and a clean visual appearance.

9. Why Choose SW as Your PVC Sealing Strips Factory

For over two decades, SW has been a trusted PVC sealing strips factory providing custom extrusion solutions for global clients.

Our Strengths:

20+ years of extrusion expertise

Advanced production equipment

Support for OEM & ODM customization

Fast sampling and mold development

Consistent quality control and ISO compliance

Worldwide shipping and technical support

We work with clients across construction, automotive, appliance, and industrial sectors, ensuring every sealing strip meets exact performance standards.

PVC sealing strips play a crucial role

PVC sealing strips play a crucial role in ensuring protection, insulation, and longevity across multiple industries. Their combination of affordability, flexibility, and durability makes them one of the most reliable sealing solutions available.

When choosing a PVC sealing strips factory, experience, customization capability, and quality control are key. With 20 years of professional manufacturing experience, SW is proud to offer high-quality PVC sealing strips tailored to your project’s exact needs.

If you are looking for a dependable partner for custom PVC sealing strips, contact SW today — your trusted source for professional extrusion and sealing solutions.

We have a PVC pipes factory of skilled engineers ready to support you in your product development journey from idea design to production.Any ideas about your product you can contact us freely,and our engineers will get back to you with a quote asap. Whatsapp +86 188 2072 7151

Who is Shuowei?

Since 2006, Shuowei is a professional extrusion profiles factory based in Guangdong, China. There are total about 51-100 people in our office. Shuowei PVC extrusion factory is committed to the design and production of extruded profiles, such as PVC pipes, PE trunking, PVC skirting line. Since its inception, we have won the wide recognition of the market and the deep trust of customers with our ingenious design, exquisite technology and the ultimate pursuit of quality.

Are you a manufacturer or a trader?

We are a Chinese top PVC extrusion profiles manufacturer and our factory is located in Huizhou. Our factory has a 16,000㎡ production base, 5+ automated extrusion profiles production lines, an annual production capacity of 30,000 tons, and serves more than 500 customers worldwide. Welcome to visit our factory!

What is your product range?

We pecialize in the design and production of high quality extrusion profiles,such as PVC pipe, ABS extrusion, PC lampshades, PVC skirting lines, PP trunking, PE profiles…

How long does the custom development process take?

We support custom extrusion products. The usual process has 4 steps: demand confirmation → 3D design/proofing → test certification → mass production (cycle 3-8 weeks).

Do you have any international certifications?

We have passed ISO 9001, CE, RoHS, SGS and other certifications, and meet the mainstream standards of Europe, America, the Middle East and Asia