PVC pipes have become one of the most widely used piping materials in the world. From residential plumbing to large-scale industrial projects, they offer durability, corrosion resistance, and cost-effectiveness.

However, to ensure long service life and safe usage, users must follow important precautions when installing, handling, and operating PVC pipe systems.

In this article, we’ll explore:

General precautions for using PVC pipes

Installation and maintenance tips

How to eliminate or reduce static electricity in PVC pipes

Why sourcing from a professional PVC pipes factory like SW ensures safer, high-quality solutions

1. Understanding PVC Pipes

Before diving into precautions, it’s useful to know why PVC pipes behave the way they do.

Lightweight: Easy to transport and install compared to metal pipes.

Corrosion resistant: No rusting like steel or iron.

Chemical resistance: Excellent for chemicals, acids, and wastewater.

Non-conductive: Since PVC is an insulator, it cannot conduct electricity. However, this property leads to static charge buildup in certain conditions (more on this later).

Versatile: Available in Schedule 40, Schedule 80, pressure pipes, drainage pipes, and electrical conduits.

These properties make PVC pipes highly versatile but also mean they need specific handling and safety considerations. Learn more about PVC pipes <A Comprehensive Guide to PVC Pipes from a Factory’s Vision>

2. General Precautions When Using PVC Pipes

2.1 Storage and Handling

Store pipes on a flat surface away from direct sunlight (UV can degrade unprotected PVC).

Avoid dropping or dragging pipes to prevent cracks and scratches.

Stack pipes in layers, supported every 1–2 meters, to prevent warping.

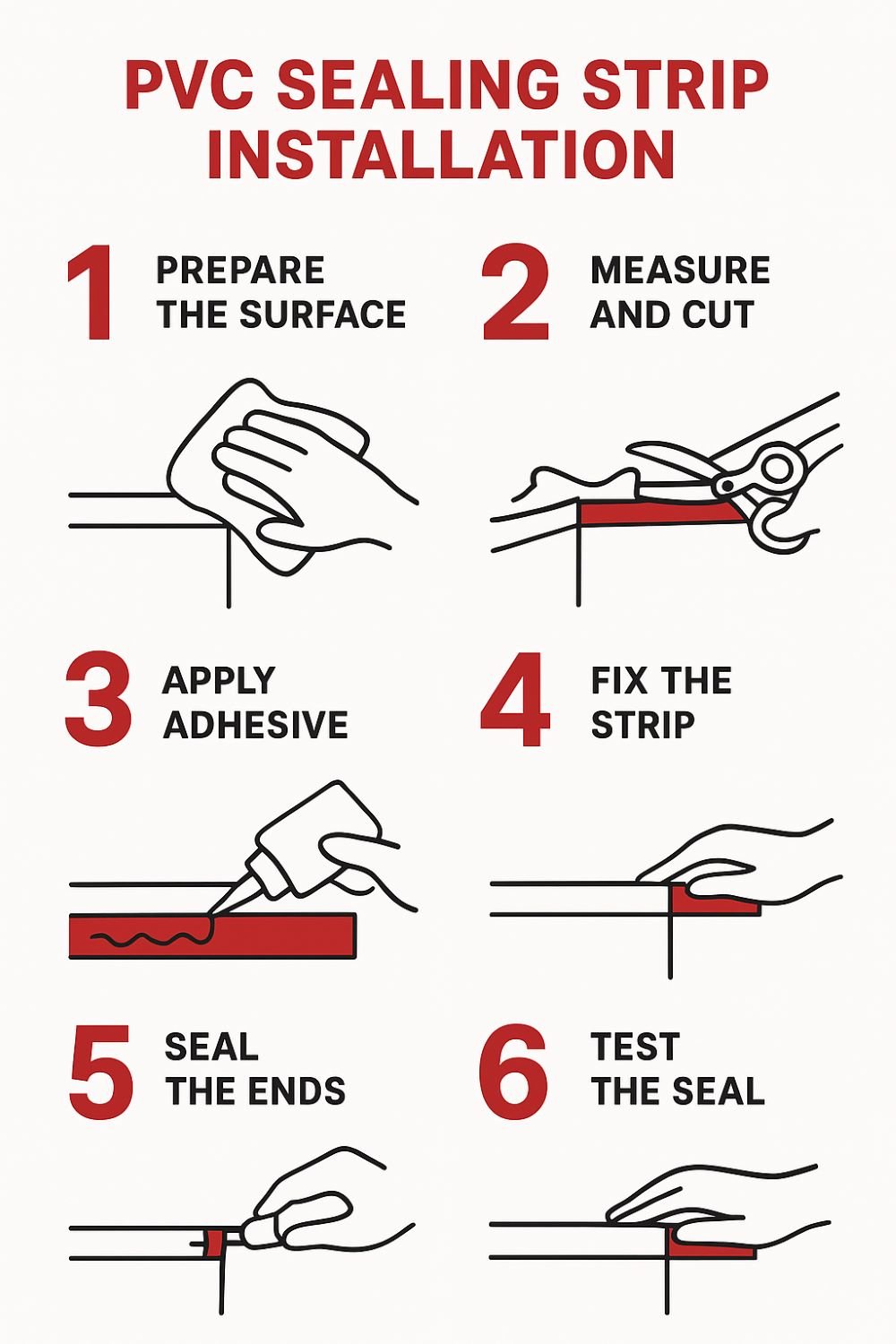

2.2 Installation Precautions

Do not install PVC pipes near open flames or high heat sources.

Allow for thermal expansion and contraction by using expansion joints or flexible couplings.

Use only approved solvent cement and primer for joining. Incompatible adhesives can weaken joints.

Avoid over-tightening threaded connections — overtightening may crack the fittings.

2.3 Pressure and Flow Considerations

Select the right pressure class for the intended application.

For compressed air systems, avoid using standard PVC pipes unless specifically rated — risk of bursting exists.

Maintain proper slope (usually 1–2%) in drainage systems to avoid blockages.

3. Environmental and Safety Considerations

Chemical exposure: While PVC resists many chemicals, certain solvents and hydrocarbons may damage it. Always check chemical compatibility charts.

UV exposure: For outdoor installation, either use UV-stabilized PVC or apply protective paint/coating.

Temperature limits: PVC softens at high temperatures (above 60°C / 140°F). Avoid hot water transport unless using CPVC (chlorinated PVC).

4. Maintenance and Long-Term Use

Inspect joints regularly for leaks.

Flush pipelines to prevent scaling or deposits.

Replace aged or brittle pipes after decades of service.

Avoid striking PVC with sharp tools or heavy objects.

5. Static Electricity in PVC Pipes

One of the lesser-known issues with PVC pipes is static electricity buildup. Since PVC is a non-conductive material, friction from fluids moving inside the pipe (especially powders, gases, or high-velocity liquids) can generate static charges.

5.1 Why Static Charge is a Problem

Shock hazard: Although usually low energy, static discharge can startle workers.

Ignition risk: In environments with flammable gases, vapors, or dust, static sparks can ignite explosions.

Attraction of dust: Static electricity attracts dust and debris, which may contaminate fluid systems.

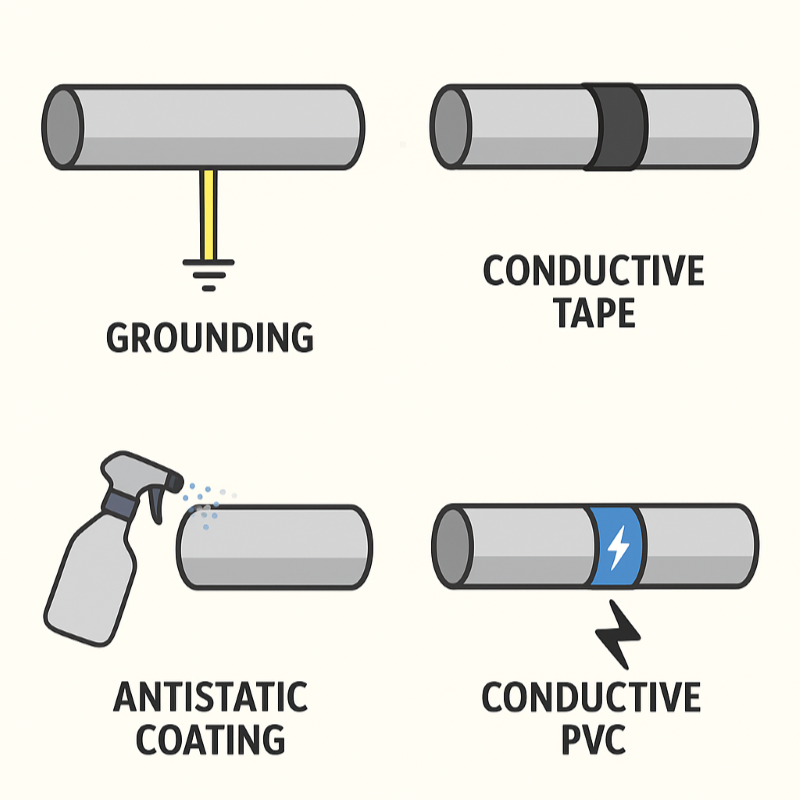

6. How to Eliminate or Reduce Static Electricity in PVC Pipes

There are several methods to minimize static buildup in PVC piping systems:

6.1 Grounding and Conductive Layers

Use PVC pipes with conductive additives (carbon-loaded PVC). These allow static charges to dissipate.

Wrap the pipe in conductive tape connected to a grounding system.

In industrial settings, consider metallic grounding wires in contact with the pipe exterior.

6.2 Antistatic Coatings

Apply antistatic sprays or coatings on the outer surface of PVC pipes.

These coatings reduce charge accumulation by making the surface slightly conductive.

6.3 Humidity Control

Maintaining moderate humidity levels reduces static buildup, since moisture helps dissipate charges.

In dry climates, humidification systems can significantly reduce static problems.

6.4 Flow Rate and System Design

Avoid extremely high velocities for fluids inside PVC pipes, as friction increases static charge.

Use smooth bends and avoid sharp turns in design to reduce turbulence.

6.5 Alternative Materials for High-Risk Applications

For conveying flammable gases or explosive powders, PVC pipes may not be the safest option. Consider conductive piping alternatives, or special antistatic PVC manufactured by professional factories.

7. Application-Specific Precautions

7.1 Plumbing and Water Supply

Use food-grade, certified pipes for potable water.

Flush the system before first use to remove solvent residues.

7.2 Drainage and Sewage

Maintain slope for efficient flow.

Install access points for maintenance.

7.3 Irrigation

Protect exposed PVC pipes from sunlight with coverings.

Use proper filtration to prevent clogging from debris.

7.4 Industrial Systems

In chemical plants, double-check chemical compatibility.

In powder or gas transport, always consider static electricity precautions.

8. Why Work with a Professional PVC Pipes Factory

Choosing the right manufacturer is just as important as correct installation.

A reliable PVC pipes factory like SW ensures:

Consistent quality with ISO-certified production

Pipes engineered for high pressure, drainage, and industrial use

Customized solutions such as UV-resistant PVC or antistatic PVC for special applications

Technical support to guide safe installation and operation

With 20+ years of expertise, SW provides pipes that not only meet industry standards but also ensure long-term safety and reliability.Learn more about SW PVC pipes factory.

PVC pipes safe use

PVC pipes are strong, durable, and versatile — but safe use requires proper handling, installation, and maintenance.

Key takeaways:

Store and install PVC pipes correctly to avoid damage.

Consider environmental factors such as temperature, UV, and chemical exposure.

Pay special attention to static electricity prevention in applications involving gas, powders, or high fluid velocity.

Work with a trusted PVC pipes factory like SW to access professional-grade solutions and expert guidance.

By following these precautions, you can maximize the safety, efficiency, and lifespan of PVC piping systems in any application.

We have a PVC pipes factory of skilled engineers ready to support you in your product development journey from idea design to production.Any ideas about your product you can contact us freely,and our engineers will get back to you with a quote asap. Whatsapp +86 188 2072 7151

Who is Shuowei?

Since 2006, Shuowei is a professional extrusion profiles factory based in Guangdong, China. There are total about 51-100 people in our office. Shuowei PVC extrusion factory is committed to the design and production of extruded profiles, such as PVC pipes, PE trunking, PVC skirting line. Since its inception, we have won the wide recognition of the market and the deep trust of customers with our ingenious design, exquisite technology and the ultimate pursuit of quality.

Are you a manufacturer or a trader?

We are a Chinese top PVC extrusion profiles manufacturer and our factory is located in Huizhou. Our factory has a 16,000㎡ production base, 5+ automated extrusion profiles production lines, an annual production capacity of 30,000 tons, and serves more than 500 customers worldwide. Welcome to visit our factory!

What is your product range?

We pecialize in the design and production of high quality extrusion profiles,such as PVC pipe, ABS extrusion, PC lampshades, PVC skirting lines, PP trunking, PE profiles…

How long does the custom development process take?

We support custom extrusion products. The usual process has 4 steps: demand confirmation → 3D design/proofing → test certification → mass production (cycle 3-8 weeks).

Do you have any international certifications?

We have passed ISO 9001, CE, RoHS, SGS and other certifications, and meet the mainstream standards of Europe, America, the Middle East and Asia