In modern construction, interior design, and safety management, anti-slip strips play a vital role. These simple yet highly effective components help prevent accidents, enhance safety, and extend the durability of flooring surfaces. Whether used in residential, commercial, or industrial spaces, anti-slip strips are a cost-effective and versatile solution.

At SW, we are a professional extruded PVC product manufacturer with 20 years of expertise. Our specialty includes producing high-quality PVC anti-slip strips that meet global standards for safety, performance, and durability. In this blog, we will explore what anti-slip strips are, how they work, their key benefits, various applications, and why businesses and homeowners alike rely on them.

What Are Anti-Slip Strips?

An anti-slip strip is a specially designed insert or attachment applied to floors, stairs, or other walking surfaces to increase traction and reduce the risk of slipping. They are typically made from durable materials such as PVC, aluminum, or rubber, and are often textured or ribbed to enhance grip.

PVC anti-slip strips, in particular, have become one of the most popular choices due to their lightweight, affordable, and long-lasting nature. They can be used indoors and outdoors, in both wet and dry environments, making them suitable for multiple industries.

Why Anti-Slip Strips Are Essential

Accident Prevention – Slipping is one of the most common causes of injury in both homes and workplaces. Installing an anti-slip strip significantly reduces this risk.

Compliance with Safety Regulations – Many industries must follow safety codes that require non-slip surfaces, especially in areas with heavy foot traffic.

Low Maintenance Solution – Anti-slip strips are easy to clean and maintain compared to traditional anti-slip flooring solutions.

Cost-Effective Safety Upgrade – Instead of replacing entire floors or staircases, simply applying an anti-slip strip can dramatically improve safety.

Types of Anti-Slip Strips

There are several types of anti-slip strips, each suited to specific needs:

PVC Anti-Slip Strips – Affordable, versatile, and available in multiple colors. Excellent for residential and commercial use.

Aluminum Anti-Slip Strips – Heavy-duty and durable, often used in industrial environments.

Rubber Anti-Slip Strips – Flexible and ideal for wet areas such as bathrooms, swimming pools, and outdoor pathways.

Adhesive Anti-Slip Strips – Easy to install, commonly used for temporary safety needs.

Applications of Anti-Slip Strips

1. Residential Spaces

Anti-slip strips are commonly installed on:

Staircases

Bathroom floors

Kitchen entrances

Balconies and outdoor patios

PVC anti-slip strips are particularly popular for homes because they are lightweight, decorative, and easy to install.

2. Commercial Buildings

In offices, retail shops, and shopping malls, anti-slip strips ensure customer safety while maintaining an aesthetic appearance. They can be integrated into stairs, ramps, and tiled walkways.

3. Industrial Facilities

Factories, warehouses, and logistics hubs often require heavy-duty anti-slip strips to handle high traffic and machinery movement. Aluminum and PVC anti-slip strips provide the necessary grip to reduce hazards.

4. Public Spaces

Anti-slip strips are widely used in airports, train stations, and hospitals to comply with public safety requirements. PVC anti-slip strips offer both safety and durability in these high-footfall environments.

5. Outdoor Applications

Outdoor staircases, walkways, and swimming pool decks often face wet conditions. PVC and rubber anti-slip strips are water-resistant and weatherproof, making them ideal for such environments.

Benefits of PVC Anti-Slip Strips

Compared to other materials, PVC anti-slip strips stand out due to:

Durability – Resistant to corrosion, chemicals, and UV rays.

Cost-Effectiveness – Lower production and installation costs.

Design Flexibility – Available in various colors, textures, and shapes.

Lightweight Nature – Easy to handle and install without professional tools.

Eco-Friendly Options – Many PVC anti-slip strips can be produced using recyclable materials.

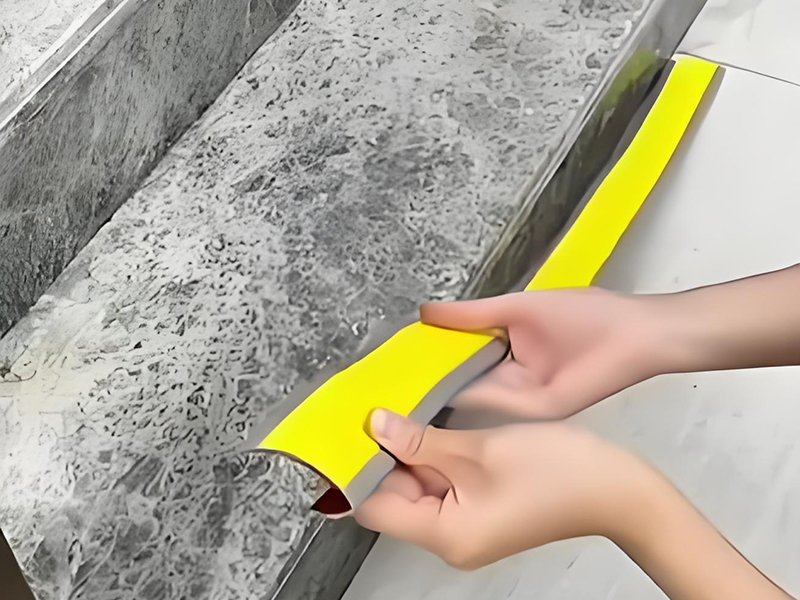

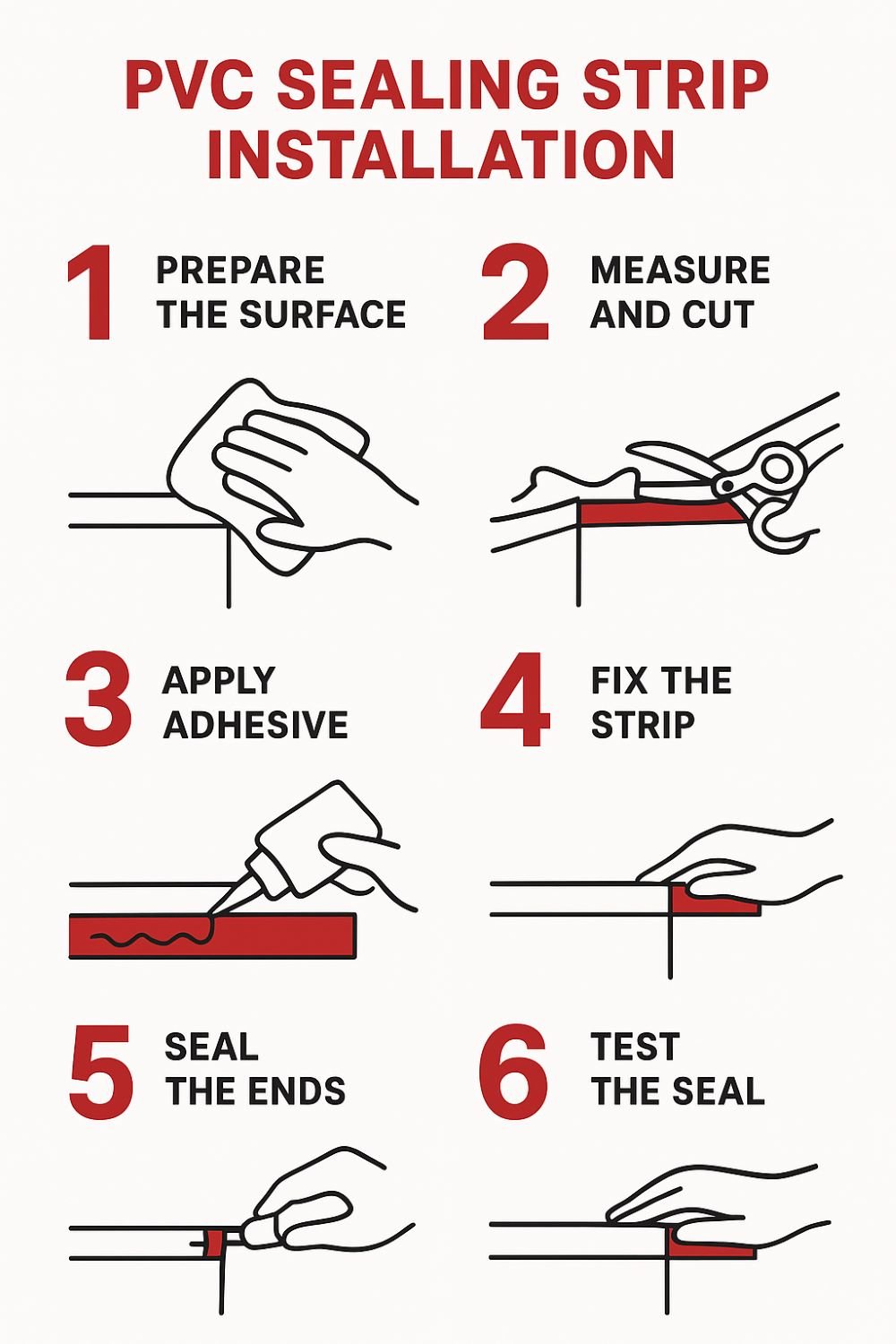

Installation of Anti-Slip Strips

Installing an anti-slip strip is straightforward and can be done with minimal tools. The process generally involves:

Cleaning the surface thoroughly.

Measuring and cutting the strip to fit the required area.

Securing it with adhesive backing, screws, or clips.

Ensuring the strip is tightly fixed without air bubbles or loose ends.

For PVC anti-slip strips, installation is quick and cost-efficient, making them a preferred choice for DIY projects as well as large-scale construction.

Maintenance Tips

To maximize the lifespan of your anti-slip strip, regular maintenance is recommended:

Routine Cleaning – Wipe with a damp cloth or mop to remove dirt and debris.

Inspection – Check periodically for any signs of wear or lifting edges.

Replacement – Replace damaged or heavily worn strips promptly to maintain safety.

Real-World Use Cases

Hotels – Using PVC anti-slip strips in staircases and bathrooms enhances guest safety.

Schools – Preventing slips in hallways and playground steps reduces student injuries.

Factories – Anti-slip strips reduce workplace accidents, ensuring compliance with safety laws.

Transportation Hubs – Airports and train stations rely on anti-slip strips to manage large passenger flow safely.

Why Choose SW as Your PVC Anti-Slip Strip Supplier

As a professional PVC anti-slip strip factory, SW has over 20 years of extrusion manufacturing experience. Our products are:

Made with high-quality raw materials.

Customizable in color, size, and texture.

Tested for durability and safety standards.

Exported globally to serve both residential and industrial clients.

When you choose SW, you’re choosing a trusted partner committed to delivering safe, durable, and cost-effective anti-slip solutions.

The demand for anti-slip strips

The demand for anti-slip strips continues to grow across residential, commercial, and industrial sectors due to their critical role in safety enhancement. Among various options, PVC anti-slip strips stand out for their affordability, versatility, and ease of use.

Whether you are a homeowner looking to improve safety at home or a business seeking compliance with safety standards, anti-slip strips provide a practical solution. With decades of expertise, SW ensures high-quality PVC anti-slip strips tailored to customer needs.

Investing in the right anti-slip strip today means building a safer and more reliable environment for tomorrow.

We have a PVC pipes factory of skilled engineers ready to support you in your product development journey from idea design to production.Any ideas about your product you can contact us freely,and our engineers will get back to you with a quote asap. Whatsapp +86 188 2072 7151

Who is Shuowei?

Since 2006, Shuowei is a professional extrusion profiles factory based in Guangdong, China. There are total about 51-100 people in our office. Shuowei PVC extrusion factory is committed to the design and production of extruded profiles, such as PVC pipes, PE trunking, PVC skirting line. Since its inception, we have won the wide recognition of the market and the deep trust of customers with our ingenious design, exquisite technology and the ultimate pursuit of quality.

Are you a manufacturer or a trader?

We are a Chinese top PVC extrusion profiles manufacturer and our factory is located in Huizhou. Our factory has a 16,000㎡ production base, 5+ automated extrusion profiles production lines, an annual production capacity of 30,000 tons, and serves more than 500 customers worldwide. Welcome to visit our factory!

What is your product range?

We pecialize in the design and production of high quality extrusion profiles,such as PVC pipe, ABS extrusion, PC lampshades, PVC skirting lines, PP trunking, PE profiles…

How long does the custom development process take?

We support custom extrusion products. The usual process has 4 steps: demand confirmation → 3D design/proofing → test certification → mass production (cycle 3-8 weeks).

Do you have any international certifications?

We have passed ISO 9001, CE, RoHS, SGS and other certifications, and meet the mainstream standards of Europe, America, the Middle East and Asia