In modern construction, manufacturing, and industrial design, PVC sealing strips have become essential components for ensuring durability, safety, and energy efficiency. From preventing water leakage to reducing vibration and air infiltration, PVC sealing strips serve as versatile sealing and protection solutions across multiple industries.

As a professional manufacturer with 20 years of experience, SW specializes in extruding PVC sealing strips tailored to meet a wide range of customer requirements. This guide explores everything you need to know about PVC sealing strips — including their types, benefits, manufacturing process, applications, and selection tips — to help you make the right choice for your project.

What Are PVC Sealing Strips?

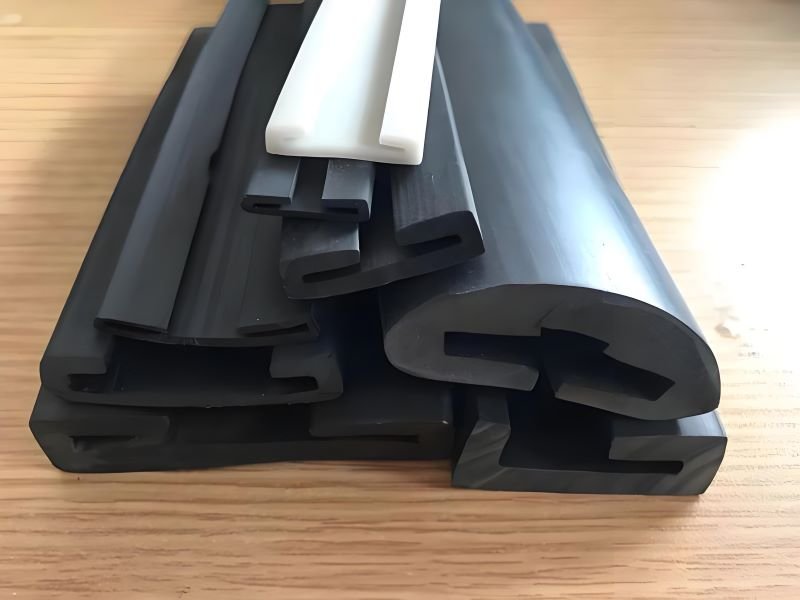

PVC sealing strips are flexible plastic extrusions made primarily from polyvinyl chloride (PVC). They are used to seal gaps, joints, or connections between surfaces to prevent the passage of liquids, air, dust, and noise. These strips are often installed around doors, windows, machinery panels, and vehicles to provide a tight, protective barrier.

Key Features

Excellent resistance to water, oil, and chemical corrosion.

Durable and long-lasting under normal environmental conditions.

Flexible yet strong enough to maintain a secure seal.

Cost-effective and easy to install compared to rubber or silicone alternatives.

Why PVC Is the Ideal Material for Sealing Strips

PVC (polyvinyl chloride) is a synthetic polymer known for its versatility and durability. When extruded into sealing strips, it provides several advantages over other materials such as rubber, silicone, or EPDM.

1. Durability

PVC is highly resistant to environmental wear and tear, including moisture, UV exposure, and temperature changes. This makes PVC sealing strips ideal for both indoor and outdoor applications.

2. Flexibility

PVC’s flexibility allows it to adapt to irregular surfaces and maintain a tight seal even under compression or vibration.

3. Chemical Resistance

PVC offers strong resistance to acids, oils, and chemicals, making it suitable for industrial applications where chemical exposure is common.

4. Cost-Effectiveness

Compared to silicone or EPDM, PVC sealing strips offer a significantly lower production cost while still delivering excellent sealing performance.

5. Ease of Customization

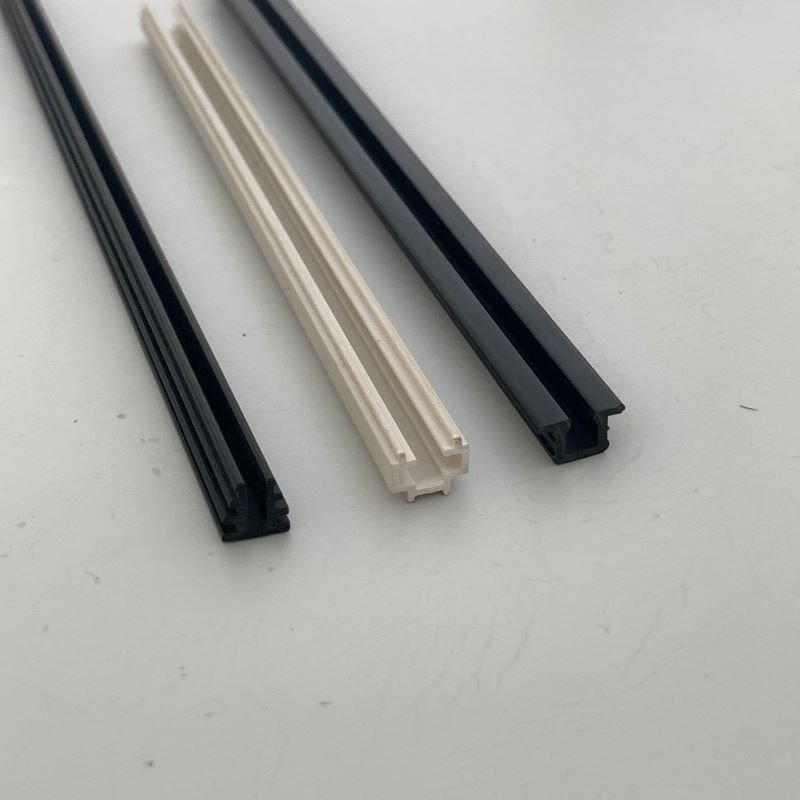

PVC can be extruded into different shapes, sizes, and hardness levels (measured in Shore A) to meet specific customer requirements.

Common Types of PVC Sealing Strips

1. Door and Window Sealing Strips

These strips are designed to prevent air and water infiltration in residential and commercial buildings. They improve energy efficiency by maintaining temperature control and reducing noise.

Applications:

Household doors and windows

Office buildings

Industrial enclosures

2. Automotive Sealing Strips

Used in car doors, trunks, and sunroofs, PVC sealing strips protect against water, dust, and wind while reducing vibration and noise.

Applications:

Vehicle doors and windows

Trunk lids and engine compartments

RVs and caravans

3. Machinery Sealing Strips

Industrial machines often require reliable sealing to protect mechanical components from dust, moisture, and oil contamination.

Applications:

Electrical cabinets

HVAC systems

Manufacturing machinery

4. Refrigerator Sealing Strips

PVC sealing strips are also widely used in the refrigeration industry to maintain insulation and prevent air leakage.

Applications:

Refrigerator and freezer doors

Cold storage facilities

5. Construction and Infrastructure Strips

In civil construction, PVC sealing strips are used to seal expansion joints and water-retaining structures such as tunnels, dams, and bridges.

Applications:

Concrete expansion joints

Waterproofing systems

Drainage channels

The Manufacturing Process of PVC Sealing Strips

As a professional PVC sealing strips factory, SW follows a detailed and controlled manufacturing process to ensure consistent quality and performance.

Step 1: Raw Material Selection

High-quality PVC resin is combined with additives such as plasticizers, stabilizers, and pigments to achieve desired flexibility, color, and durability.

Step 2: Extrusion

The PVC compound is melted and extruded through a precision die that shapes it into the desired sealing strip profile. This is a critical step that determines the strip’s dimensions and surface finish.

Step 3: Cooling and Calibration

The newly extruded strip passes through a cooling system to stabilize its shape and ensure dimensional accuracy.

Step 4: Cutting and Coiling

The cooled strips are cut into standard lengths or coiled for bulk packaging, depending on client requirements.

Step 5: Quality Inspection

Each batch undergoes thorough inspection for surface defects, hardness, flexibility, and sealing performance.

Step 6: Packaging and Shipping

Finally, strips are packaged securely to avoid deformation during transit and shipped to customers worldwide.

Advantages of PVC Sealing Strips

Waterproof and Dustproof: Perfect for sealing applications in wet or dusty environments.

Noise Reduction: Helps dampen sound in automotive and construction uses.

Thermal Insulation: Prevents air leakage and enhances energy efficiency.

Chemical Resistance: Ideal for industrial environments exposed to oils or solvents.

Versatility: Suitable for a wide range of applications across multiple industries.

Customizable: Can be extruded in different colors, shapes, and hardness levels.

Easy Maintenance: Simple to clean and replace when necessary.

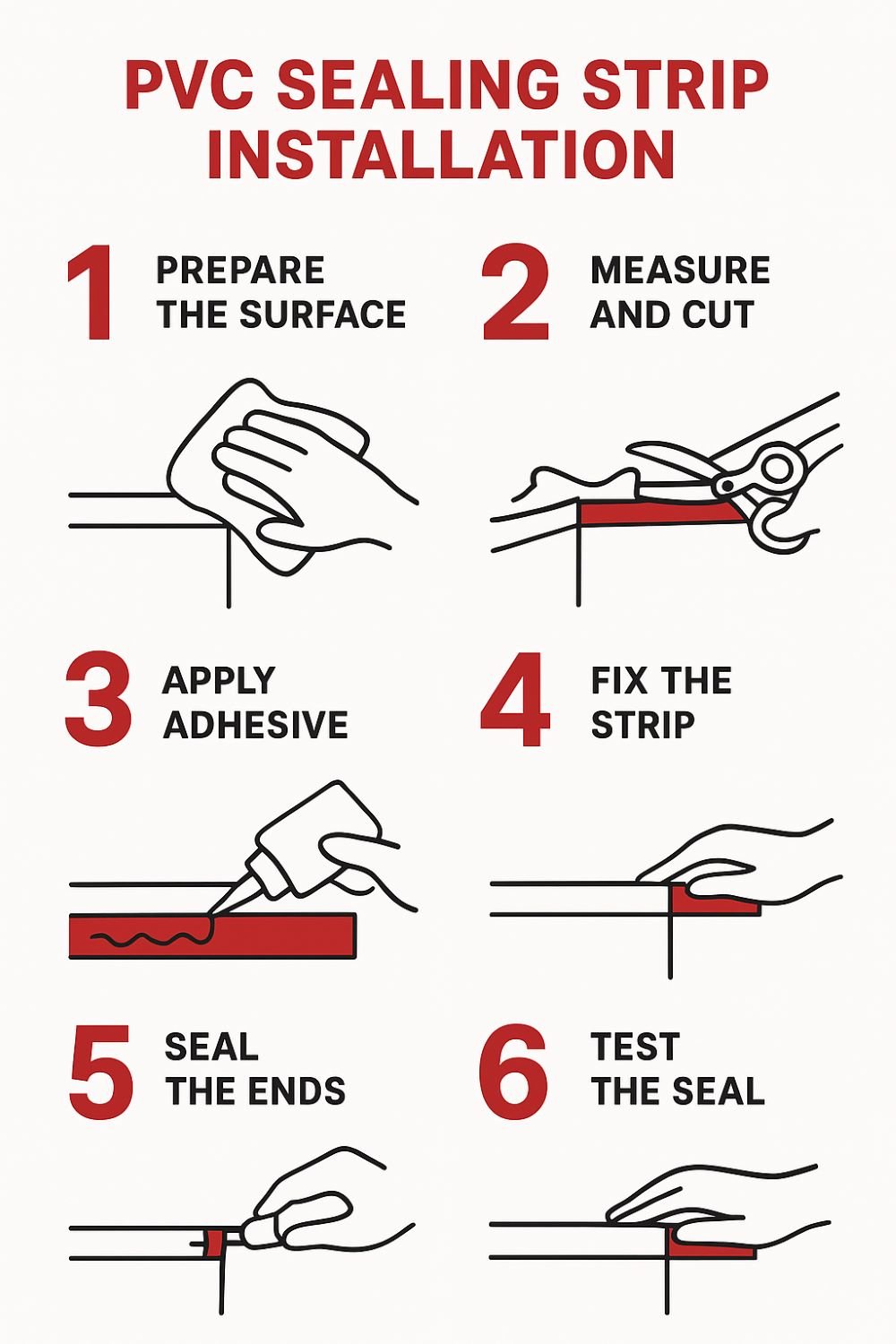

How to Install PVC Sealing Strips

Proper installation is key to achieving a durable and effective seal. Here’s a general installation guide:

Step 1: Clean the Surface

Ensure the installation area is free of dust, grease, and moisture.

Step 2: Measure and Cut

Measure the required length and cut the PVC sealing strip to size using a sharp utility knife or scissors.

Step 3: Apply Adhesive or Insert

Depending on the design, either apply adhesive to the back of the strip or insert it into the designated groove.

Step 4: Press Firmly

Press the strip along the surface, ensuring even contact and a continuous seal.

Step 5: Check for Gaps

Inspect the installation to make sure there are no air gaps or uneven sections.

Maintenance and Usage Tips

Regular Cleaning: Use mild soap and water to clean the strips. Avoid harsh chemicals.

Avoid High Heat: PVC may deform under excessive temperatures.

Check Adhesion: Over time, reapply adhesive if strips begin to loosen.

Inspect Periodically: Replace worn or damaged strips to maintain performance.

Avoid Stretching: Do not overstretch the strip during installation to prevent shrinkage later.

Comparison: PVC vs. Other Materials

| Material | Cost | Flexibility | Durability | Chemical Resistance | Common Applications |

|---|---|---|---|---|---|

| PVC | Low | High | High | High | Doors, windows, machinery |

| EPDM Rubber | Medium | High | Very High | Medium | Automotive, outdoor use |

| Silicone | High | Medium | Very High | Very High | Medical, food, electronics |

| Neoprene | Medium | Medium | Medium | Medium | Industrial sealing |

| Foam | Low | High | Low | Low | Temporary sealing, insulation |

PVC remains the best balance of performance, price, and customization — making it the top choice for most sealing applications.

Industries Using PVC Sealing Strips

Automotive Manufacturing

Building and Construction

HVAC and Electrical Equipment

Food Storage and Refrigeration

Marine and Transportation

Machinery and Industrial Equipment

Each of these industries relies on the unique combination of flexibility, durability, and chemical resistance offered by PVC sealing strips.

Why Choose SW as Your PVC Sealing Strips Factory

With two decades of specialization in plastic extrusion, SW stands out as a leading PVC sealing strips manufacturer trusted by clients around the world.

Our strengths include:

Over 20 years of manufacturing experience.

Advanced extrusion technology ensuring precision and consistency.

Customized solutions based on your project requirements.

High-quality raw materials ensuring durability and performance.

Fast delivery and competitive pricing.

International certifications for quality and safety.

SW supports OEM and ODM production, providing tailored sealing solutions that fit specific customer needs — from automotive applications to construction systems.

The right PVC sealing strip can significantly improve the safety

The right PVC sealing strip can significantly improve the safety, efficiency, and durability of your product or building system. Its unique combination of flexibility, affordability, and resistance to environmental factors makes PVC one of the most practical materials for sealing applications today.

Whether you are looking for door and window sealing, automotive weatherstripping, or industrial sealing solutions, SW’s PVC sealing strips offer unmatched performance and customization.

By partnering with a professional PVC sealing strips factory like SW, you ensure not only superior product quality but also expert guidance, consistent supply, and long-term reliability.

We have a PVC pipes factory of skilled engineers ready to support you in your product development journey from idea design to production.Any ideas about your product you can contact us freely,and our engineers will get back to you with a quote asap. Whatsapp +86 188 2072 7151

Who is Shuowei?

Since 2006, Shuowei is a professional extrusion profiles factory based in Guangdong, China. There are total about 51-100 people in our office. Shuowei PVC extrusion factory is committed to the design and production of extruded profiles, such as PVC pipes, PE trunking, PVC skirting line. Since its inception, we have won the wide recognition of the market and the deep trust of customers with our ingenious design, exquisite technology and the ultimate pursuit of quality.

Are you a manufacturer or a trader?

We are a Chinese top PVC extrusion profiles manufacturer and our factory is located in Huizhou. Our factory has a 16,000㎡ production base, 5+ automated extrusion profiles production lines, an annual production capacity of 30,000 tons, and serves more than 500 customers worldwide. Welcome to visit our factory!

What is your product range?

We pecialize in the design and production of high quality extrusion profiles,such as PVC pipe, ABS extrusion, PC lampshades, PVC skirting lines, PP trunking, PE profiles…

How long does the custom development process take?

We support custom extrusion products. The usual process has 4 steps: demand confirmation → 3D design/proofing → test certification → mass production (cycle 3-8 weeks).

Do you have any international certifications?

We have passed ISO 9001, CE, RoHS, SGS and other certifications, and meet the mainstream standards of Europe, America, the Middle East and Asia