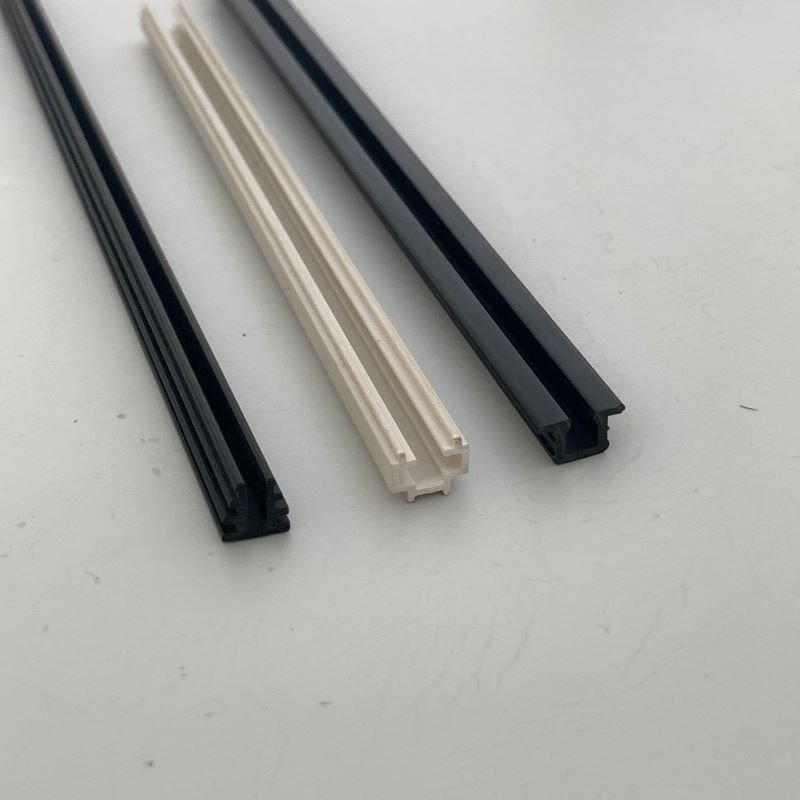

Leading PVC sealing strips solutions

How to find the right PVC sealing strips factory? As a professional PVC sealing strips factory in China, SW has served many brand customers with customized solutions.

What are PVC sealing strips?

PVC sealing strips are made of polyvinyl chloride (PVC) as the main raw material, with plasticizers and other ingredients added. They have heat resistance, toughness and ductility, and are mainly used in the door and window, furniture, automobile and curtain wall manufacturing industries. Its production process includes raw material preparation, mixing, extrusion molding and other links. The microwave vulcanization process can improve the surface finish and elasticity. The applicable temperature range is -40℃ to +120℃.

High-quality products are identified by their characteristics such as not softening at high temperatures and not breaking easily at low temperatures. When burned, they emit black smoke and leave hard residues. The density is 1.4-1.6; inferior products often have poor elasticity and are prone to aging and shrinkage due to excessive talcum powder filling. Silicone rubber sealing strips have a wider temperature resistance range (-50℃ to 200℃), burn smokelessly and odorlessly, and have a lower density (1.1-1.25) [1]. This product supports customized services and can meet the needs of scenarios such as insect control and sound insulation.

What is the function of PVC sealing strips

PVC sealing strips are primarily used for waterproofing, sealing, soundproofing, dustproofing, and energy conservation. They are suitable for use in doors, windows, furniture, and automobiles, and feature excellent processability and low cost.

PVC Sealing Strips:

Waterproofing: Prevents rain and moisture from penetrating through a physical barrier, protecting internal structures.

Sealing: Prevents airflow and foreign matter from entering, maintaining pressure balance in the space.

Soundproofing: Reduces noise transmission and enhances living comfort.

Dustproofing: Blocks dust and pollutants, maintaining a clean environment.

Energy Saving: Sealing reduces energy consumption and meets environmental requirements.

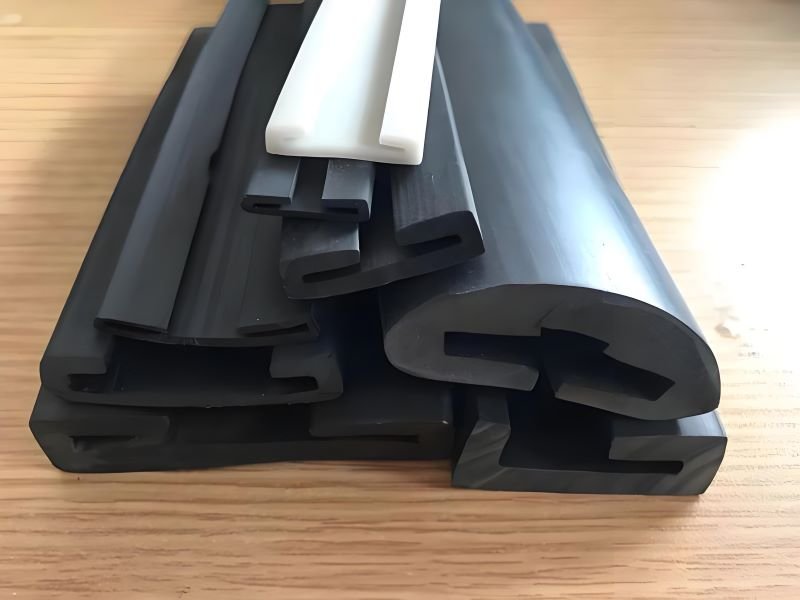

Type of sealing strips

According to the modification process and performance differences, sealing strips can be divided into the following four types

PVC sealing strips

Silicone sealing strips

EPDM sealing strips

TPV sealing strips

Application scenarios of PVC sealing strips

PVC sealing strips are sealing products made primarily from polyvinyl chloride (PVC). They are used in a variety of applications:

Construction

Doors and Windows: Used to seal the gap between glass and sash, and the joint between door panels and frames, on plastic-steel, aluminum-alloy, and wooden doors and windows, providing waterproofing and soundproofing.

Curtain Walls: Used in the curtain wall manufacturing industry, they provide leak prevention and energy savings.

Furniture and Office Equipment

Furniture Panel Edge Banding: Laminating different materials together creates color harmony, prevents moisture and deformation on the panel surface, and inhibits formaldehyde emissions.

Office Equipment: Used for surface protection and decoration of panel furniture and office desks and chairs.

Transportation

Automobiles: Used for waterproofing and soundproofing doors and windows, and other areas. Some models use PVC as the base material.

Other Applications

Home Appliances: Some appliance housings require PVC sealing strips for waterproofing and dustproofing.

How to Custom PVC sealing strips

Custom PVC sealing strips require personalized production based on specific application scenarios, dimensions, and performance requirements. The following are the key considerations and processes for customizing PVC sealing strips:

1. Clarify customization requirements: application scenario, dimensions, and performance requirements

2. Select materials and processes: open mill mixing and extrusion, pelletizing followed by extrusion molding, or direct powder extrusion

3. Production and processing: mold development, adhesive application, and surface treatment

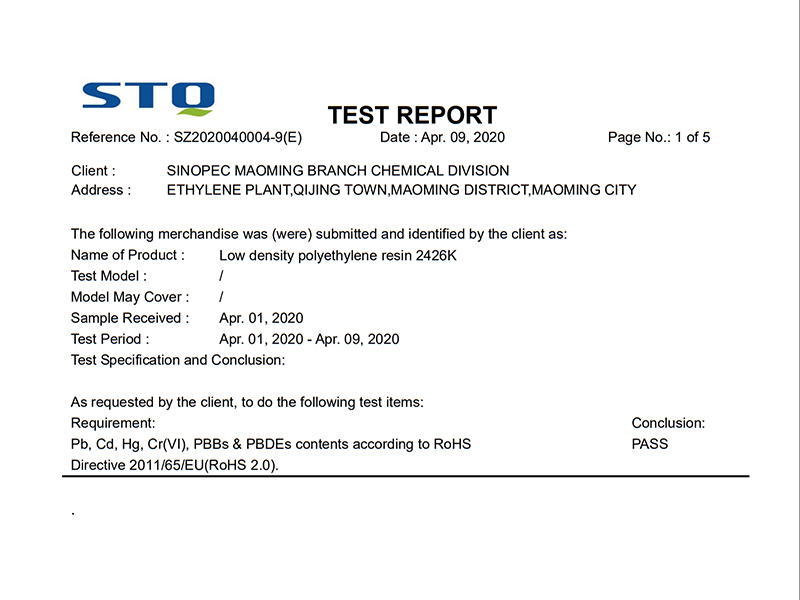

4. Quality testing and environmental requirements: performance testing and environmental standards

5. Supplier selection and cost control: We recommend selecting a manufacturer with formula development capabilities and mold processing experience.

How to choose PVC sealing strips factory

When choosing a PVC sealing strips factory, you need to consider factors such as material performance, production capacity, and after-sales service. Specific suggestions are as follows

Products

Let's see PVC sealing strips factory recommend

How to choose right PVC sealing strips

When choosing PVC sealing strips, you need to consider factors such as material properties, installation location, operating environment, and product quality. Here are some key considerations:

1. Material Properties: PVC sealing strips offer excellent processing properties and corrosion resistance, while being relatively cost-effective. However, they offer poor weather resistance. If your budget allows, consider materials such as TPV or EPDM.

2. Installation Location: Different locations require different sealing strips.

3. Quality Inspection Methods: Observe appearance, smell, perform high-temperature tests, and perform tensile tests.

4. Brand and Price: Selecting a reputable brand generally offers greater assurance.

5. Other Considerations: Measure Size: Accurately measure the gap to be sealed before purchasing, and select a sealing strip with the appropriate width and shape (e.g., L-shaped or slotted).

Get in touch

As a 20+ years custom PVC sealing strips factory, we have a team of skilled engineers ready to support you in your product development journey from prototyping to production.Any ideas about your product you can contact us freely,and our engineers will get back to you with a quote as soon as possible.